Device and method for measuring angle of tenon pressure surface of dovetail blade

An angle measurement device and blade tenon technology, which is applied in angle/taper measurement and other directions, can solve the problems that the actual value cannot be obtained, and achieve the effects of accurate and convenient measurement, accurate displacement transmission, and guaranteed transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

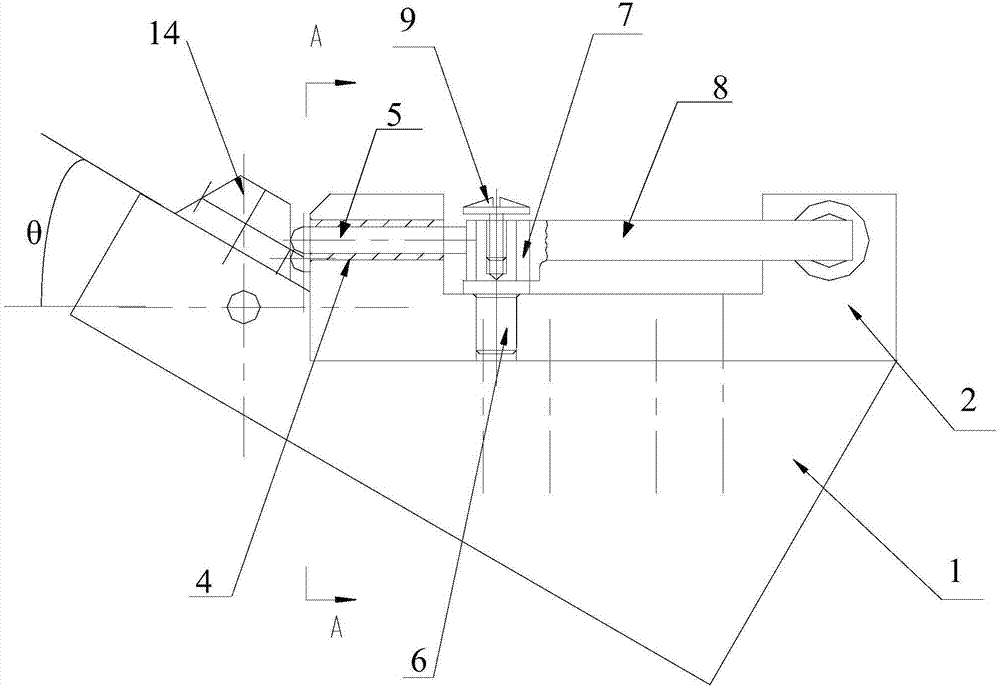

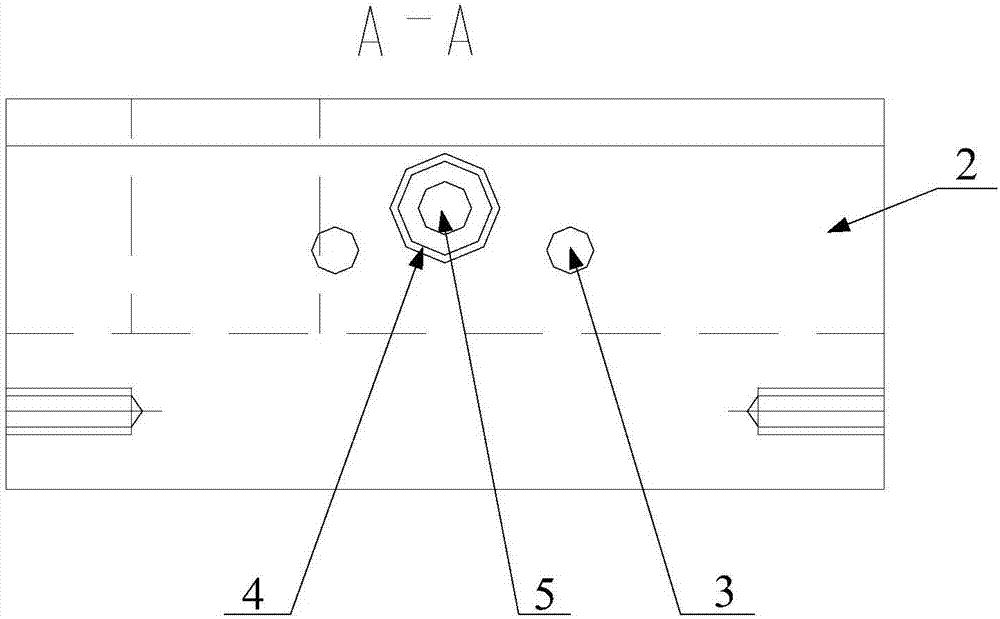

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] In the present invention, when the positioning block 2 is placed horizontally, the short-axis end face of the lever 8 faces the front side, and the long-axis end face faces the right side, which is only for clarity of description, rather than limitation of the present invention.

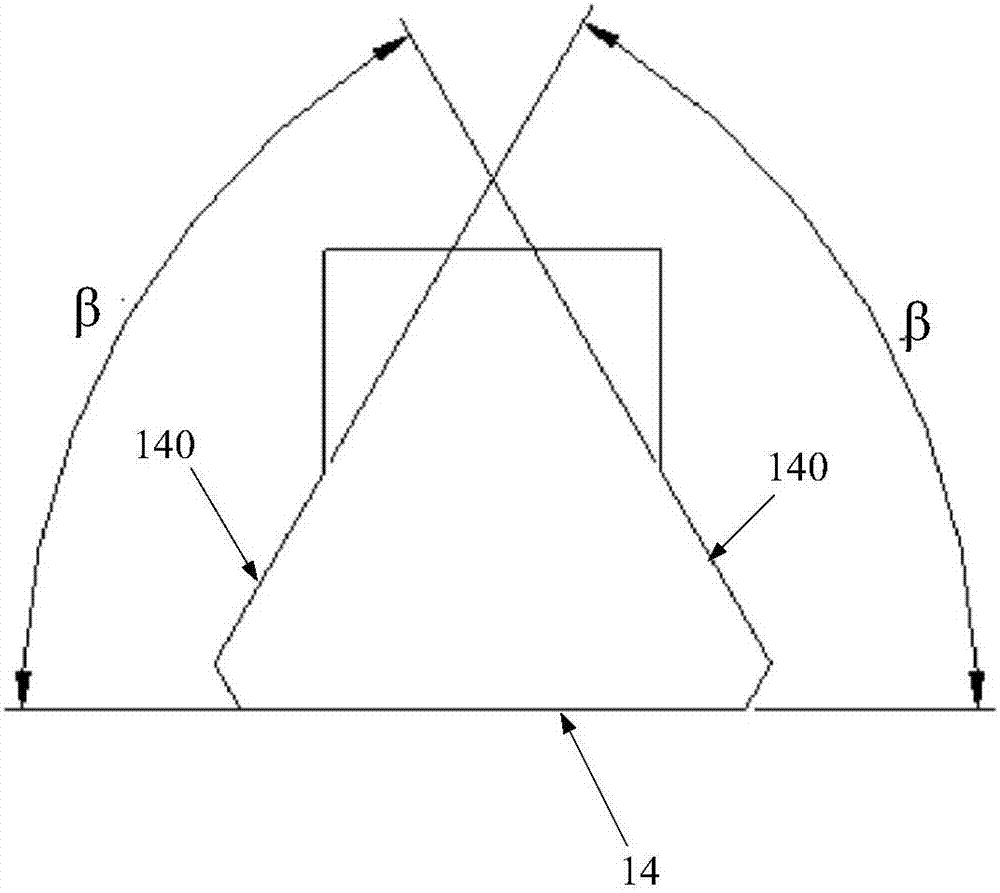

[0033] see figure 1 , the present invention adopts a standard part 14 of the dovetail blade tenon to be tested, the standard part 14 is consistent with the shape of the dovetail blade tenon to be tested, and only the actual value of the angle β of the pressure surface 140 is slightly different, wherein the dovetail blade tenon to be tested The value of the pressure surface angle β is 60°±4′, and the pressure surface angle β of the standard part 14 is considered to be equal to 60° in the present invention, and its error is ignored.

[0034] see Figure 2 to Figure 4 , the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com