Train shaft unloading groove probe

A technology for train shafts and unloading tanks, which is applied to the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, instruments, etc., which can solve problems such as easy missing detection, limited probe movement range, and no flaw detection equipment. The effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

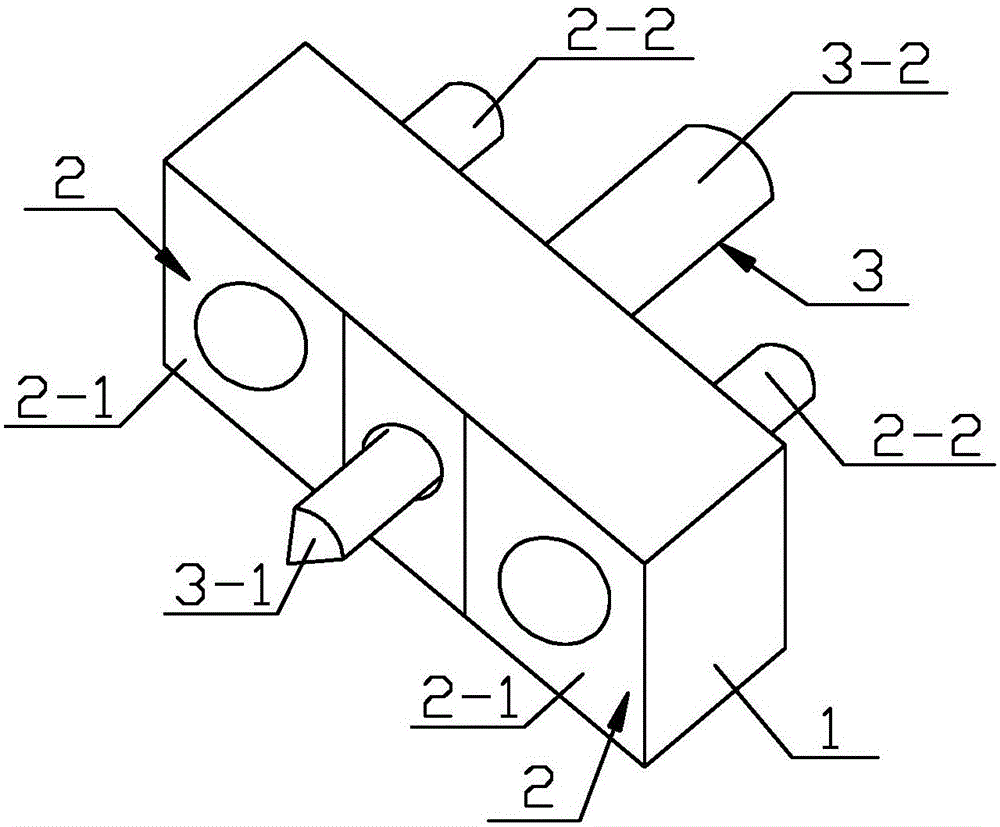

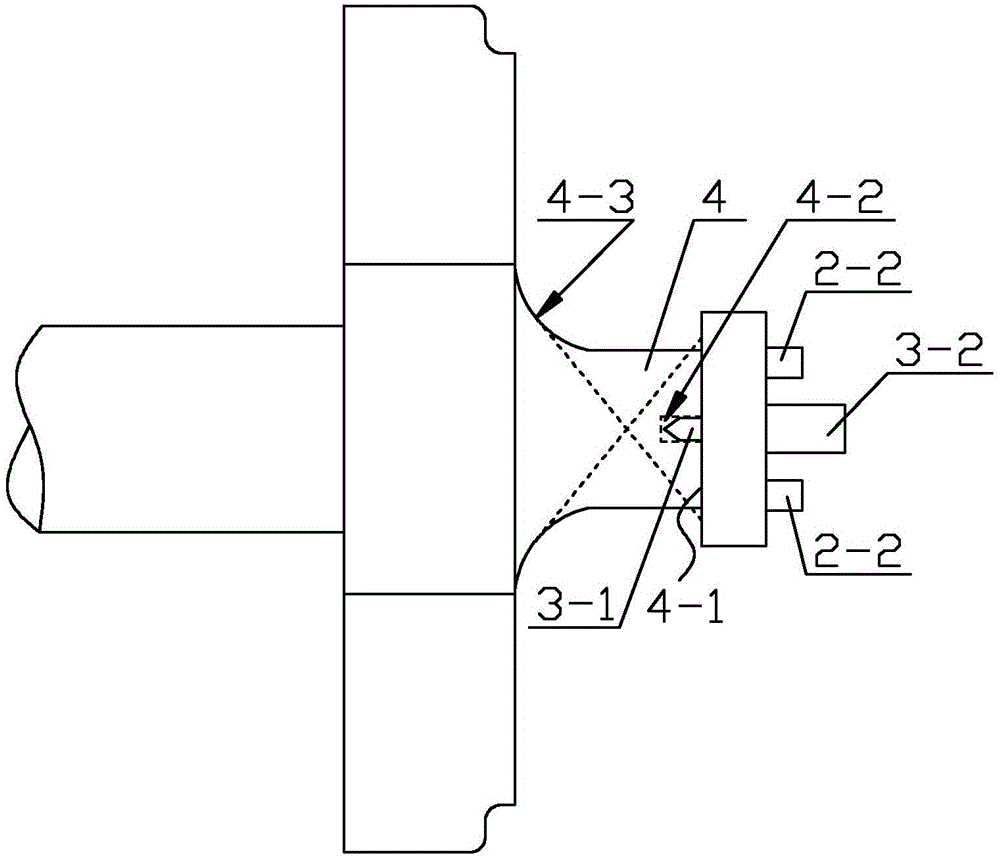

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] Such as figure 1 As shown, a train shaft unloading tank probe includes a housing 1, two longitudinal wave probes 2 and a positioning pin 3, the two longitudinal wave probes 2 are arranged inside the housing 1, and the positioning pin 3 is pierced through the housing 1 The middle part and both ends of the positioning pin 3 protrude from the shell 1, and two longitudinal wave probes 2 are symmetrically arranged on both sides of the positioning pin 3, and the longitudinal wave probe 2 includes a protective film 2-1, a probe core and a joint 2-2 in sequence , the positioning pin 3 includes a head 3-1 and a tail 3-2, and the joint 2-2 and the tail 3-2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com