Method for simulating high temperature alloy ultra-high cycle fatigue damage

A high-temperature alloy, fatigue damage technology, applied in the field of measurement and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The test material is directionally solidified superalloy DZ125, which is a cast superalloy, and heat treatment is carried out according to the conventional heat treatment system 1180°C / 2h+1230°C / 3h air cooling+1100°C / 4h air cooling+870°C / 20h. The steps of this method are as follows:

[0025] step one,

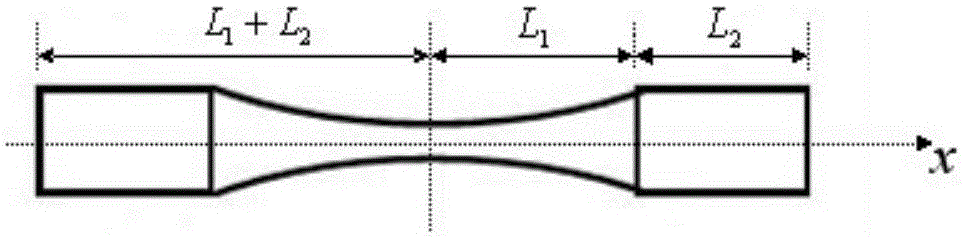

[0026] Ultrasonic fatigue test system was used to test the ultra-high cycle fatigue performance of materials. For ultrasonic fatigue, funnel-shaped specimens are usually selected, such as figure 1 shown. Firstly, the resonant frequency f of the specimen can be measured by using the ultrasonic fatigue test system, and then through the formula E d = 4l 2 f 2 ρ, density of known material ρ=8.48g / cm 3 , Specimen length ι = 50mm and resonant frequency f = 20kHz, the dynamic modulus of elasticity of the material can be obtained. The size of each stage of the sample is designed through the theory of solid vibration and the dynamic modulus of elasticity. The test frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com