Oil compensation type transformer

A transformer and compensation technology, applied in the direction of transformer/inductor cooling, etc., can solve problems such as affecting the normal use of the transformer, lack of oil in the transformer, and a large number of oil drains, avoiding local sampling distortion, improving accuracy, and facilitating operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

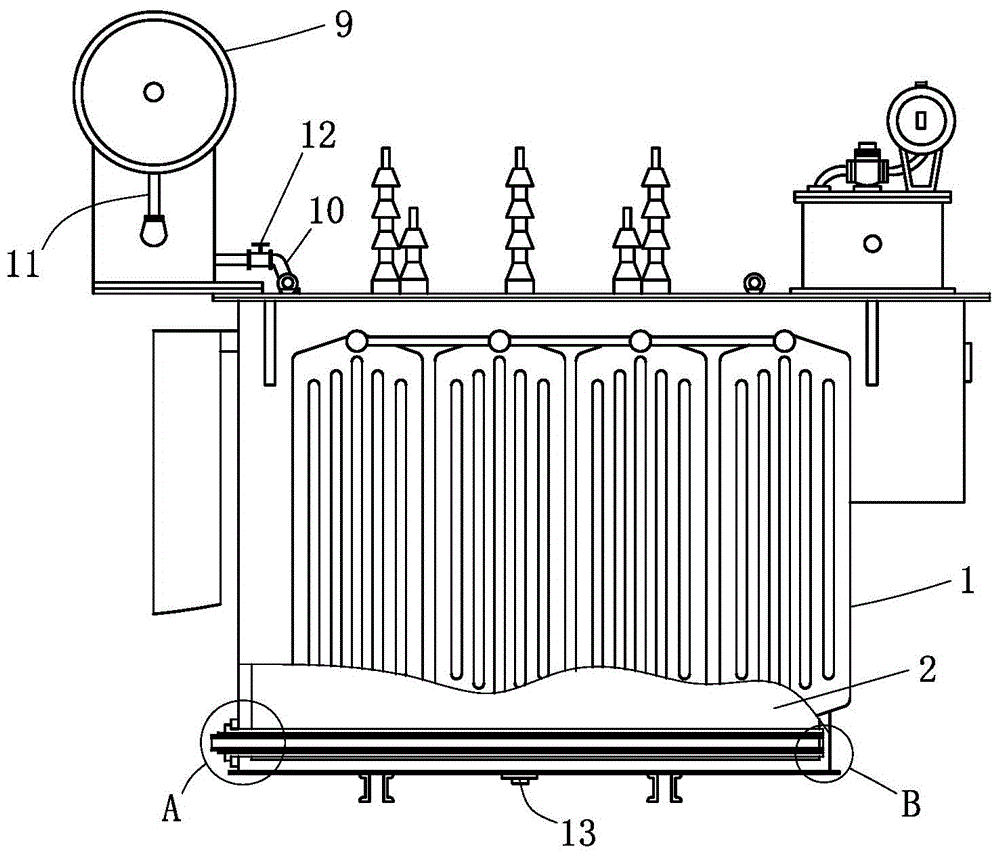

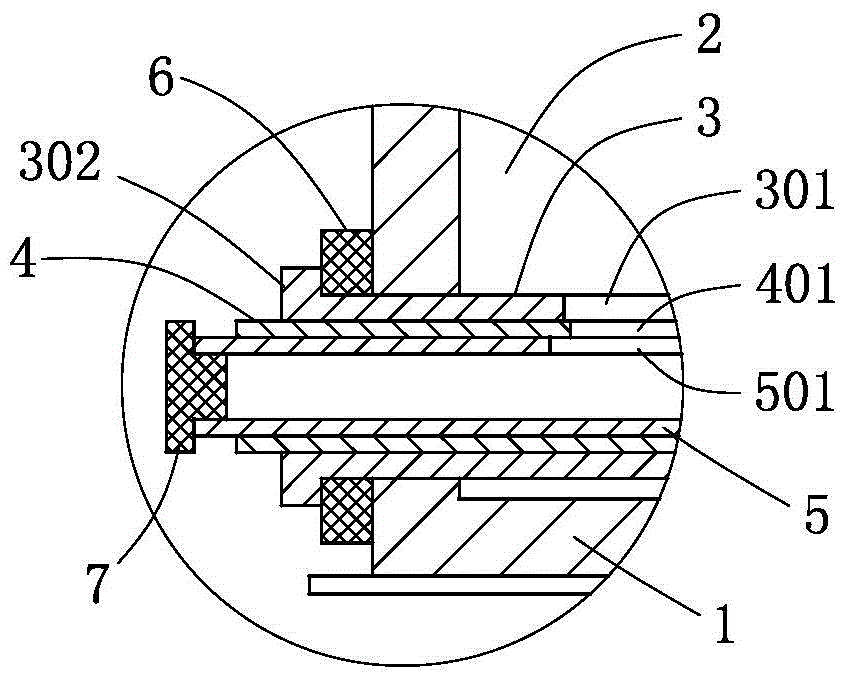

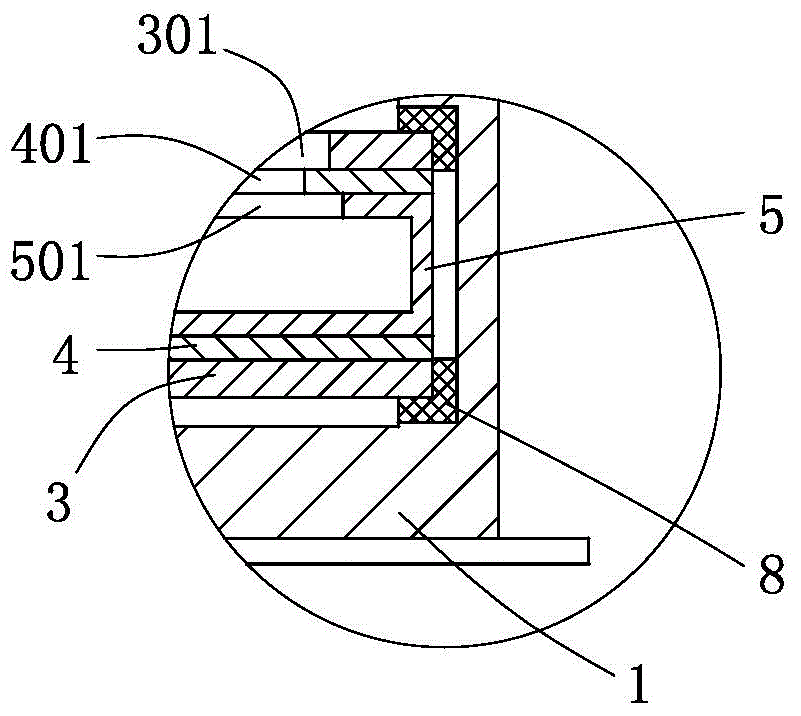

[0026] Such as figure 1 , figure 2 and image 3 Commonly shown, the present invention provides an oil volume compensation type transformer, comprising a transformer box 1, the transformer box 1 has an oil cavity 2 for containing transformer oil, and a compensation oil tank 9 is provided on the top of the transformer box 1, and the compensation oil tank 9 is connected to the oil chamber 2 through the pipeline 10, and the shut-off valve 12 is set on the pipeline 10. The bottom of the transformer box 1 is provided with a sampling port, the sampling port is connected to the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com