Display panel and manufacturing method thereof and display device and control method thereof

A technology for display panels and display units, which can be used in identification devices, semiconductor/solid-state device manufacturing, static indicators, etc., and can solve the problems of inability to form reflections, reducing light extraction efficiency, and increasing layer structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

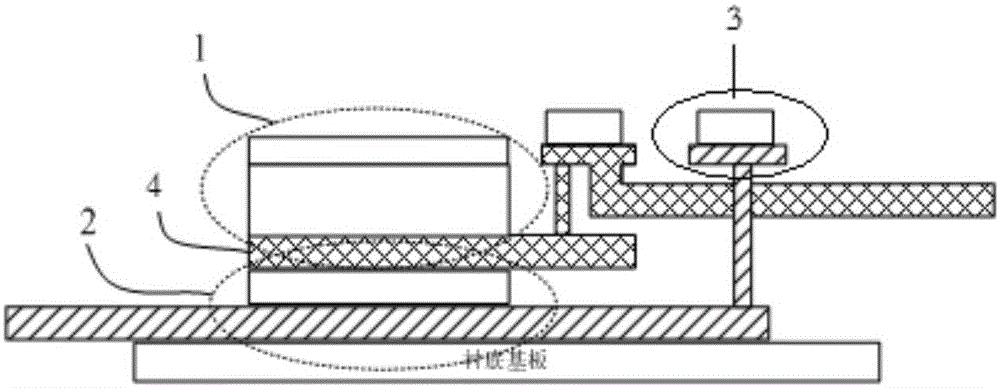

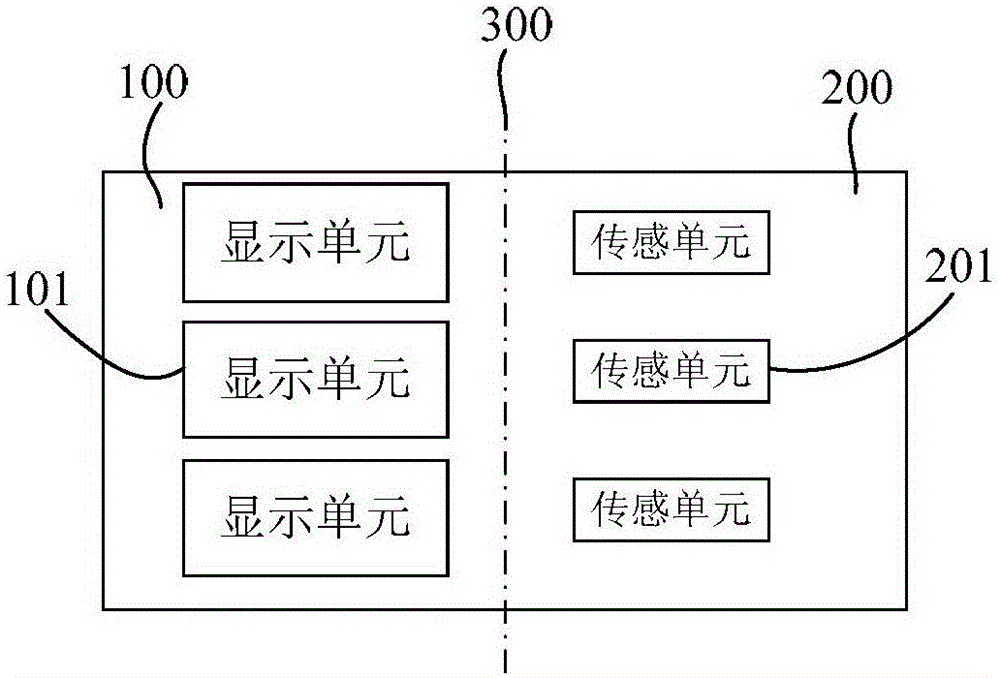

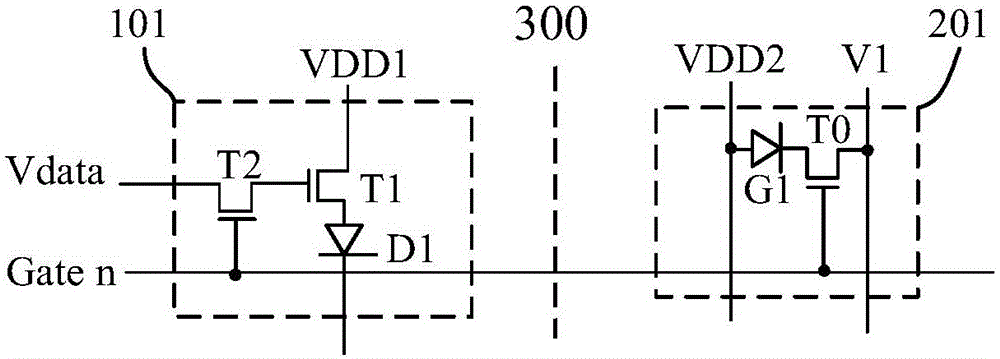

[0063] An embodiment of the present invention provides a display panel, including: a display unit and a sensing unit for detecting the brightness of the display unit. The sensing unit and the display unit are synchronously formed on different regions of the same substrate.

[0064] The display panel provided by the embodiment of the present invention includes a plurality of display units, and also includes sensing units synchronously formed on different regions of the same substrate, and the sensing units are used to detect the brightness of some display units, so as to realize brightness detection and compensation function. Generally speaking, a display unit mainly includes a display device, a thin film transistor and a signal line for controlling the operation of the display device, while the main component of a sensing unit is a photosensitive device, and the electrodes of the photosensitive device and the signal lines connected to the electrodes can be connected The metal ...

Embodiment 2

[0086] This embodiment provides a method for manufacturing a display panel, including: providing a base substrate; forming a display unit in the display area of the base substrate; Simultaneously form the sensing unit.

[0087] Therefore, in the display panel provided by this embodiment, the sensing unit used to detect the brightness of the display unit is formed synchronously with the display unit, without additional manufacturing process due to the introduction of the sensing unit, and the sensing unit is bent ( Or cut and install) attached to the top cover of the display area, after closing the top cover, the sensing unit covers the display area, then play the test picture to obtain the brightness data, and then play the test picture to obtain the brightness data, obtained by calculation The compensation value is stored and compensated according to the set compensation value after the top cover is opened, so as to solve the problem of uneven brightness.

[0088] Specific...

Embodiment 3

[0093] The embodiment of the present invention also provides a control method of a display device, the display device includes any one of the display panels in the embodiments, that is, the display panel is also provided with a sensing unit synchronously formed with the display unit, and the sensing unit is It is attached to the top cover of the display area by bending (or installing after cutting). The display device control method provided in this embodiment specifically includes:

[0094] Step 1: Trigger the brightness compensation switch to enable the brightness detection and compensation function; optionally, in this step, the brightness compensation switch can be triggered by closing the top cover.

[0095] Step 2: The display panel displays a test picture; optionally, the test picture includes: all white and all black pictures of each primary color, but is not limited thereto, and may also be other test pictures for testing brightness.

[0096] Step 3, collecting and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com