Change-over type electrical connector

An electrical connector and transfer technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of inability to determine the length of the wire, increase the production cost and difficulty of production, and achieve reasonable and effective wiring. The effect of avoiding cost cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

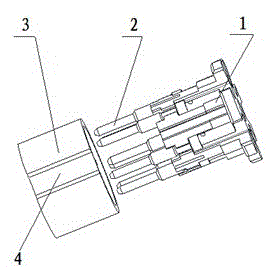

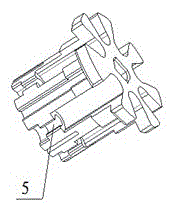

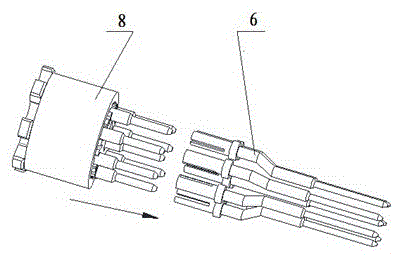

[0022] Such as figure 2 As shown, the positioning mounting plate of the crimping section, the main function of the mounting plate is to fix the crimping pin and connect the cable. Eight clips are connected to one side of the positioning mounting plate, and each clip is provided with a slot on the inner side, which is used for clipping and limiting the crimping pin. The connection point between the clamping piece and the positioning mounting plate is movable, and the clamping piece can move up and down around the connection point. There are through holes on the positioning mounting plate. In the actual installation process, pull up each clamping piece, pass the cable through the through hole, and each wire is fixedly connected to a crimping pin separately, and then the crimping Pins snap into slots to secure; then snap each snap back into place. Such as figure 1 As shown, insert the positioning mounting plate with the crimping pins into the insulating sheath, and there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com