Pneumatic tire and its manufacturing method

A technology for pneumatic tires and manufacturing methods, which is applied to pneumatic tires, tire parts, tire treads/tread patterns, etc., can solve the problems of easy perforation and easy trauma, reduce cavity resonance, and improve repair efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1 and comparative example 2

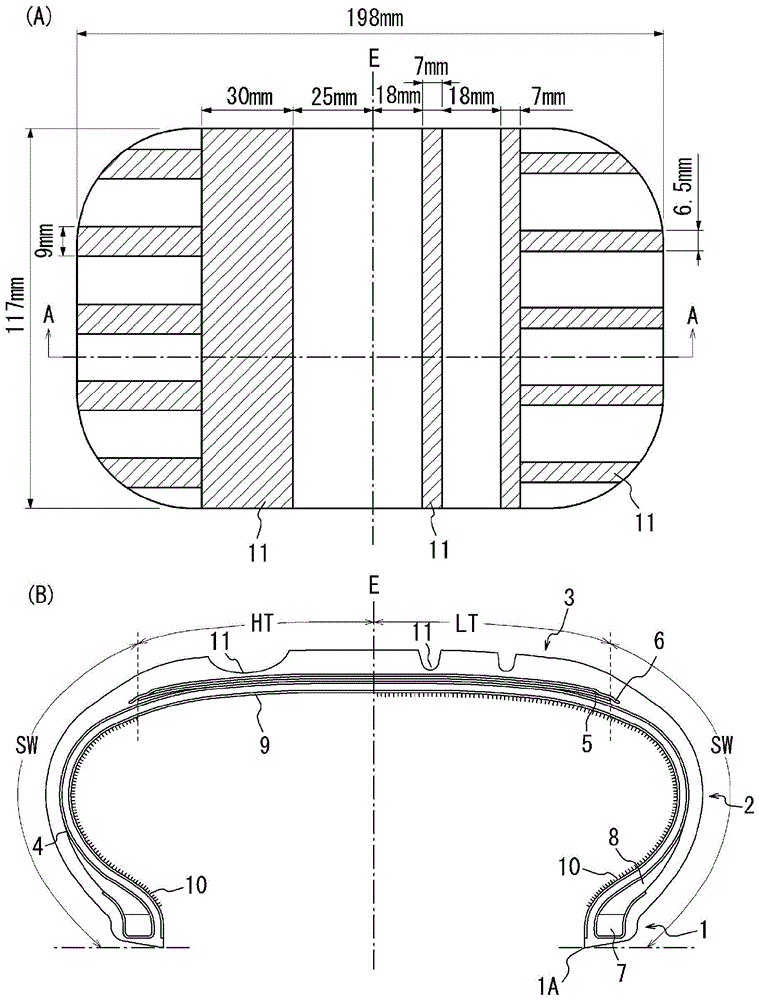

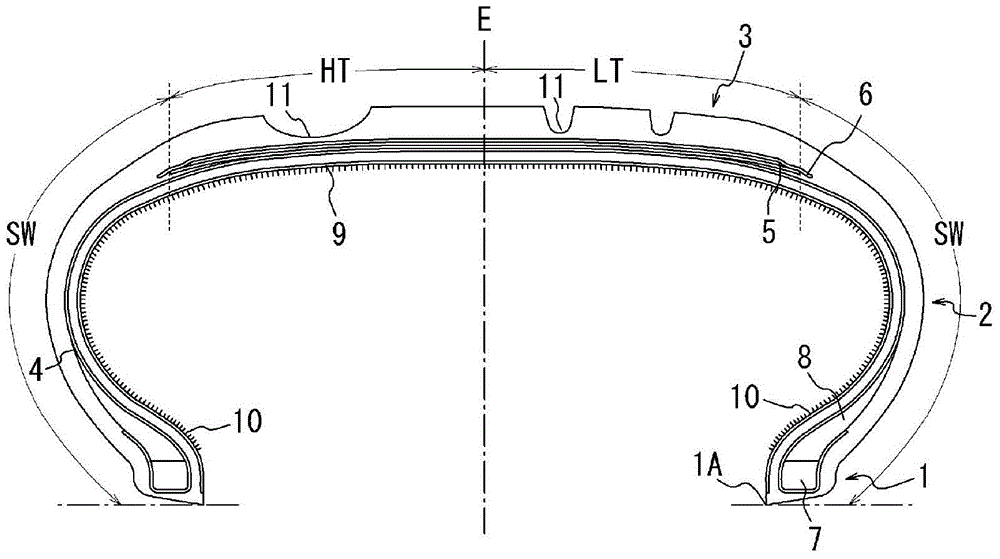

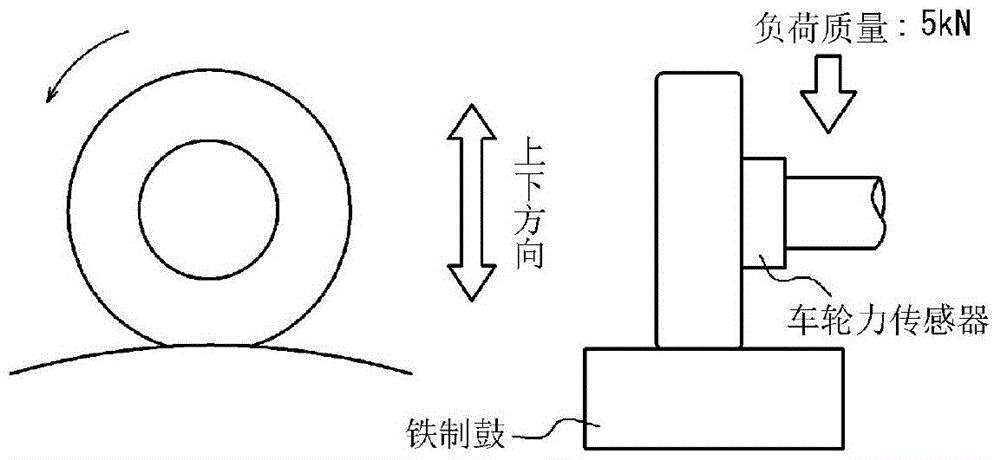

[0054] prepared with such figure 1 A tire of the same specification with the tread pattern shown, with or without short fibers made of nylon attached to predetermined areas by flocking. The cavity resonance and puncture repair efficiency of each tire were measured as described below. The tires used are those with figure 1 Tire size 255 / 35R20 for the construction shown. Specifically, the tread portion of each tire is divided into two sides by the equatorial plane E, that is, the serial side (tread half HT) and the reverse serial side (tread half LT), and the serial side Set the negative ratio to 48%, and set the negative ratio on the reversed side to 26%. Use 8.5J-20 rims. Note that the maximum width BW in the tire width direction of each belt layer is 78% of the maximum width of the tire.

[0055] Example 1 is as figure 1 The region (excluding the rim mounting portion) of the tire inner peripheral surface from the equatorial plane E to the tire radially inner end portion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com