Tire wheel assembly and run-flat core

A runflat and assembly technology, applied in the direction of wheels, pneumatic tires, tire parts, etc., can solve problems such as increased cavity resonance sound, achieve the effect of reducing friction and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

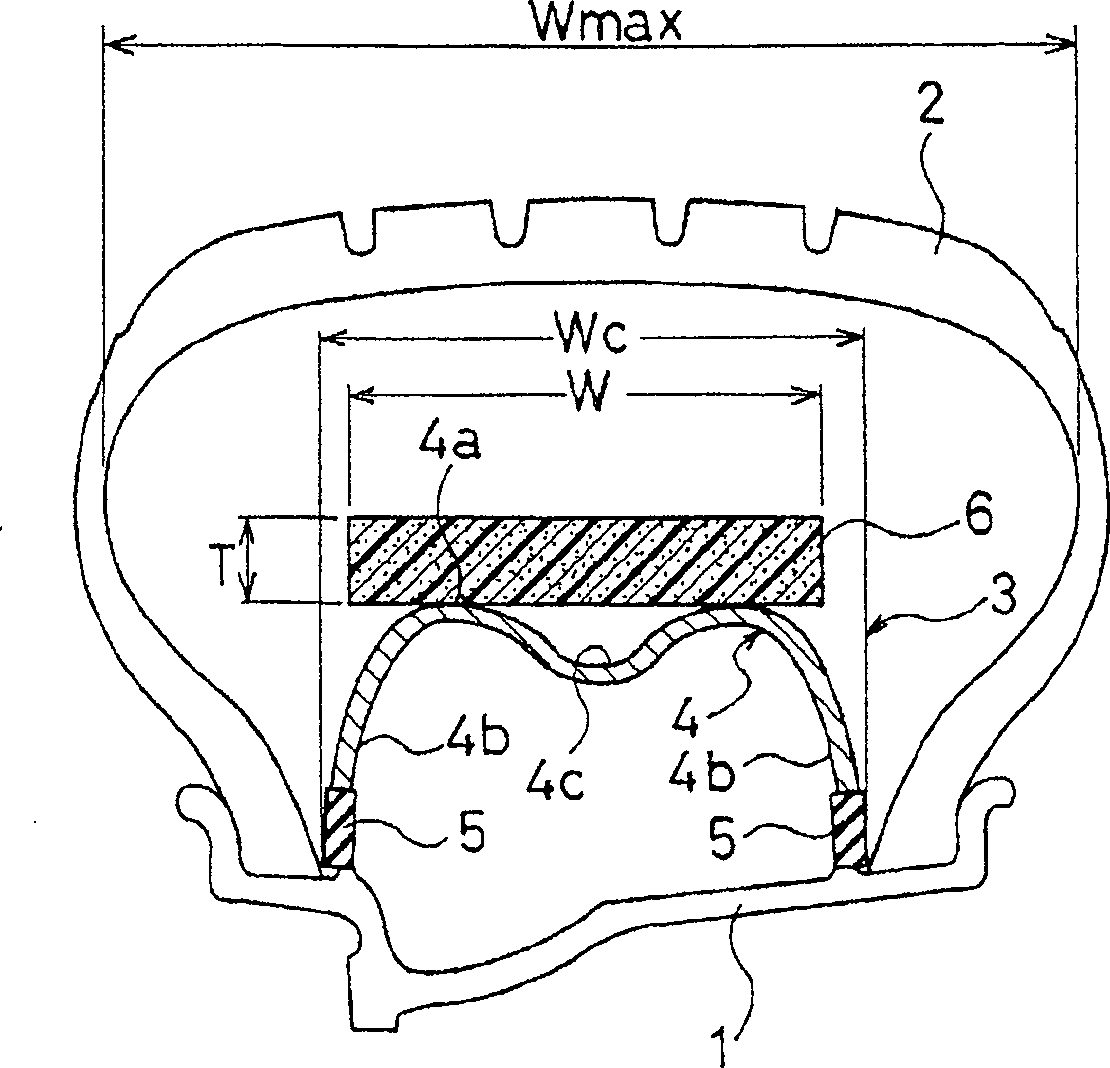

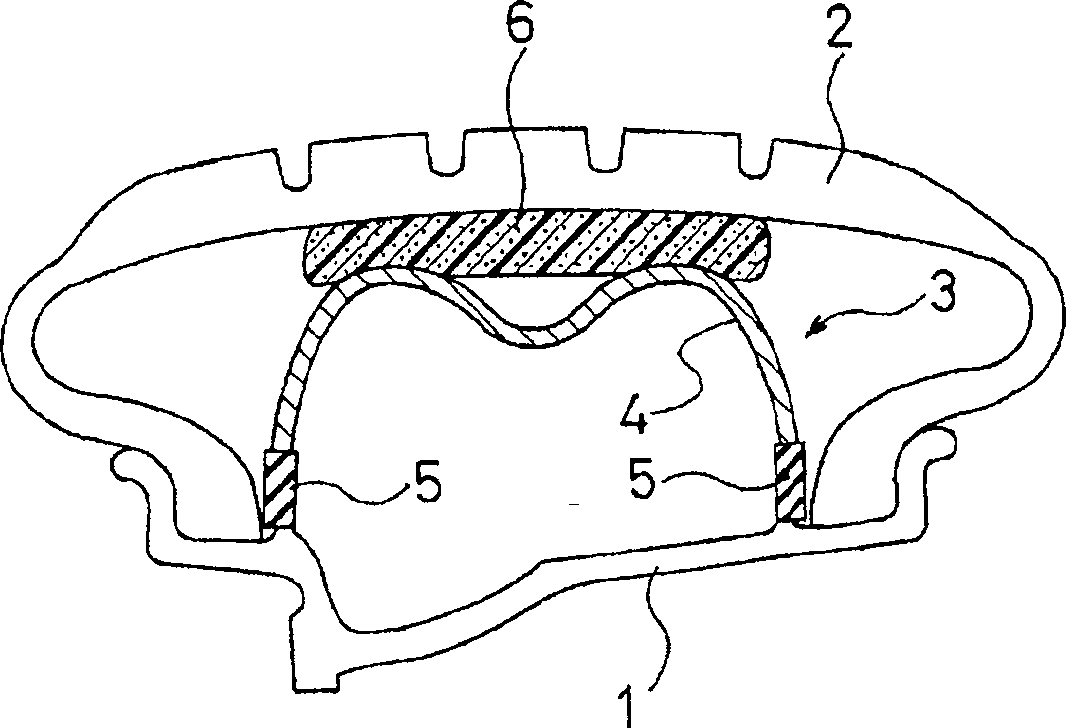

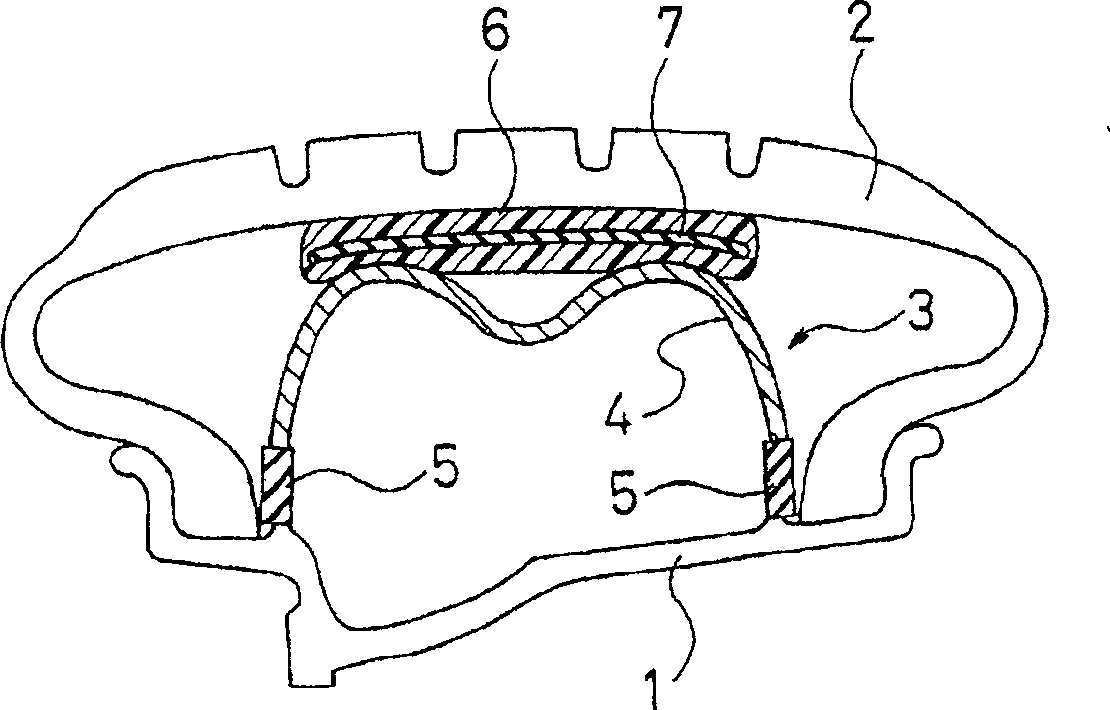

[0051] Including a pneumatic tire with a tire size of 215 / 55R16 and a wheel with a rim size of 16×7JJ, and inserting a leak air composed of a pair of elastic rings and an annular shell into the cavity formed between the pneumatic tire and the rim of the wheel In the tire wheel assembly of the core, a tire wheel assembly in which a sound absorbing material was provided on the annular shell of the runflat core was prepared (Examples 1 and 2). In addition, for comparison, a tire and wheel assembly (conventional example) in which no sound absorbing material was provided on the annular shell of the runflat was prepared.

[0052] In Example 1, a polyurethane foam having a tear strength (JIS K6301) of 4.5 N / cm and a sound absorption rate at 200 Hz (JIS A1405) of 18% was used as the sound absorbing material. In Example 2, as a sound absorbing material, a polyurethane foam having a tear strength (JIS K6301) of 5.5 N / cm and a sound absorption rate at 200 Hz (JIS A1405) of 12% was used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com