Pneumatic tire and manufacturing method thereof

A technology for pneumatic tires and tire width directions, applied to pneumatic tires, tire parts, tires, etc., can solve problems such as deterioration of fuel consumption and increase of rolling resistance of tire weight, and achieve the purpose of suppressing the deterioration of riding comfort and suppressing rolling resistance The effect of increasing and suppressing cavity resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1 and comparative example 2

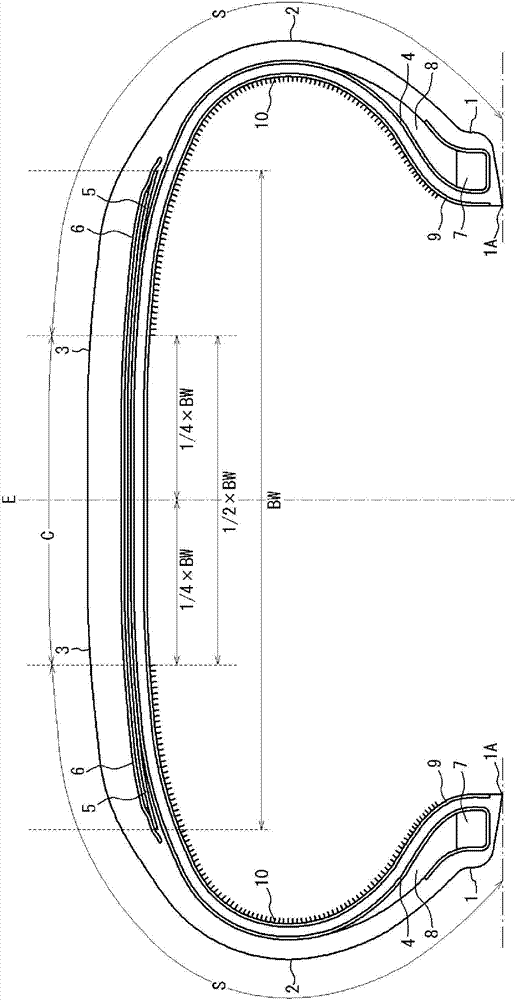

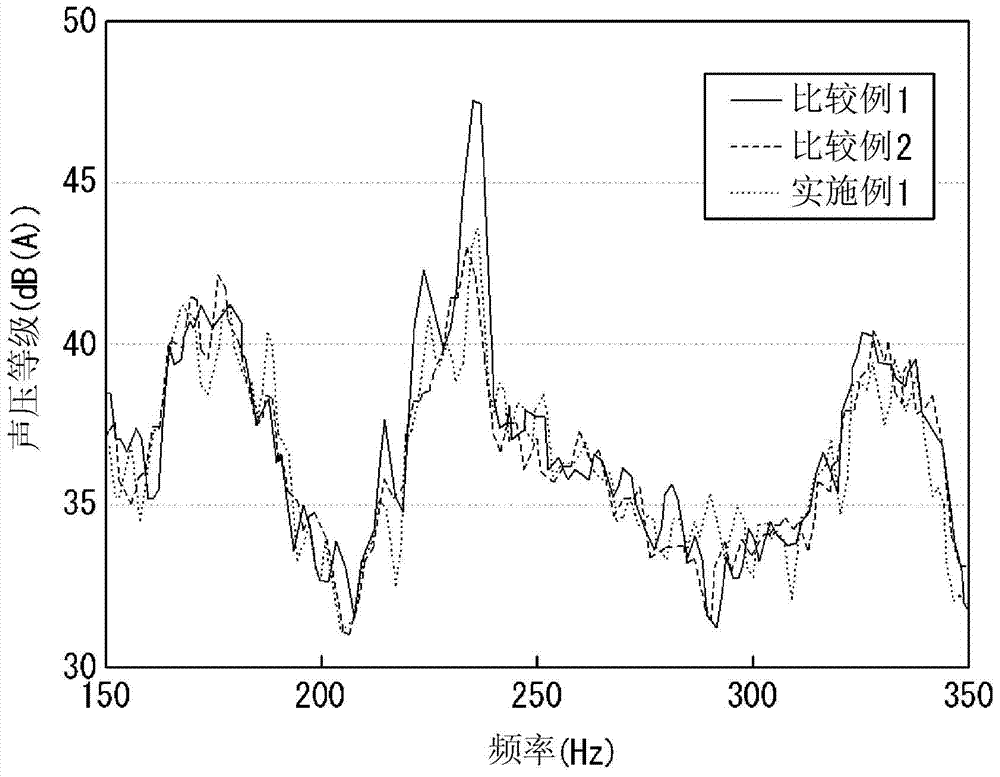

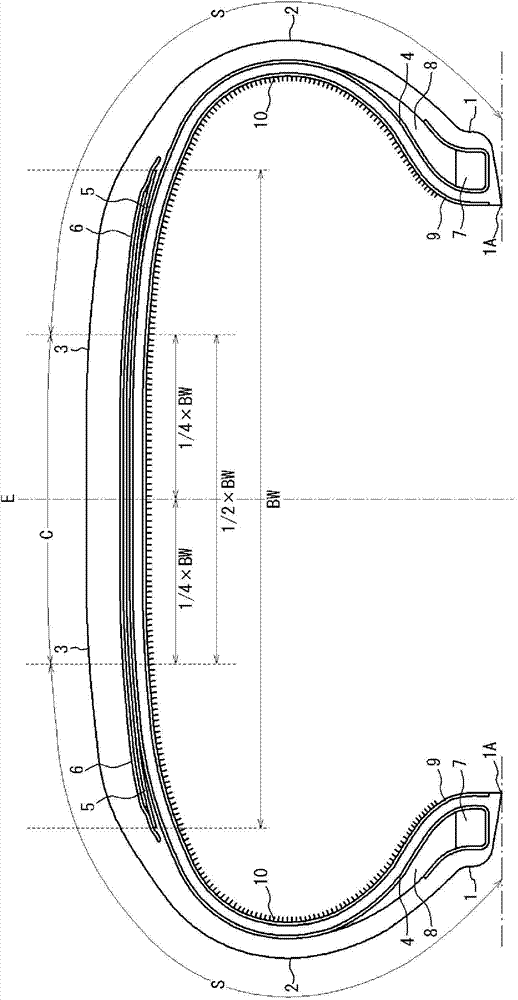

[0062] Test tires (Example 1) in which short fibers were provided in each tire side region of the tire inner peripheral surface by electrostatic flocking processing were respectively prepared by using tires sharing the same specifications in other details, in the tire inner peripheral surface A test tire without short fibers (Comparative Example 1) and a test tire with short fibers provided on the entire inner peripheral surface of the tire by electrostatic flocking (Comparative Example 2). The interior noise of an actual vehicle was measured for each of the test tires by the method described below.

[0063] In the test tire of Example 1, about 20 g of short fibers made of nylon (fiber thickness: 15 denier (denier) = φ45 μm, fiber length: 2.5 mm) were attached to each tire side region by electrostatic flocking inner surface of the tire (approximately 20,000 short fibers / square centimeter). In the tire of Example 1, the ratio of the area of the tire inner peripheral surface ...

Embodiment 2 to Embodiment 4

[0069] Except for the ratio of the area of the sub-region to which short fibers are fixedly attached to the tire inner peripheral surface of each tire side region of Examples 2 to 4 and the overall area of the tire inner peripheral surface of each tire side region as shown in Table 1 Test tires of Examples 2 to 4 were prepared in the same manner as in Example 1 except for the changes shown. For each test tire, the interior noise was measured by the method described above. The sound pressure reduction amounts of the test tires at the peak around 235 Hz (at which the noise reduction effect is observed to be most significant) are shown in Table 1 using index values relative to the results of Comparative Example 1 as a reference.

[0070] [Table 1]

[0071]

[0072] As can be understood from the results shown in Table 1, in terms of satisfactorily reducing the cavity resonance sound of the tire, it is preferable in the inner peripheral surface of the tire that the sub-re...

Embodiment 5 to Embodiment 8

[0074] Test tires of Examples 5 to 8 were prepared in the same manner as in Example 1 except that the number of short fibers per square centimeter was changed in Examples 5 to 8 as shown in Table 2. The interior noise of each test tire was measured by the method described above. The sound pressure reduction amounts of the test tires at the peak near 235 Hz (at which the noise reduction effect is observed to be most significant) are shown in Table 2 using index values relative to the results of Comparative Example 1 as a reference.

[0075] [Table 2]

[0076]

[0077] As can be understood from the results shown in Table 2, in terms of satisfactorily reducing the cavity resonance sound of the tire, it is preferable that the number of short fibers per square centimeter is 100 fibers / square centimeter or more, more preferably 1000 fibers / cm2 or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com