Device and method for the non-destructive control of metal profiles

A technology of transducers and active surfaces, which is applied in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. , to achieve a good detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

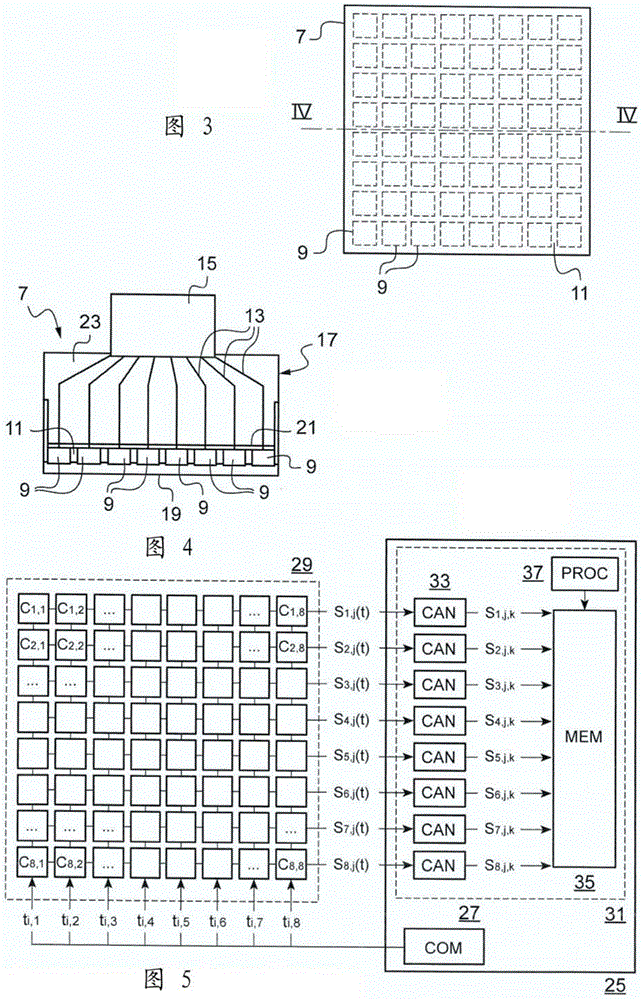

[0080] According to a first embodiment of the invention, when the main plane of the working surface of the sensor is a plane, the emission direction is inclined with respect to its normal direction, or when said plane is a curved surface, the emission direction is inclined with respect to its central region . The ultrasound beam can be considered as a deflected beam. The beam diverges about said line of sight.

[0081] According to a second embodiment of the invention, the emission direction corresponds substantially to its normal when the main plane of the working surface of the sensor is a plane, or to its central region when said plane is curved. The ultrasound beams are divergent. In particular, the beam is defocused.

[0082] now refer to Figure 6A .

[0083] The figure shows a multi-element sensor C, which is generally planar and square in shape, with a geometric center referenced S.

[0084] The direction of propagation D of the ultrasound beam, also referred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com