Screw rod electric clamp

An electric and screw technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of simple structure, complex structure, high labor cost, etc., and achieve the effect of strong clamping, tight fit and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

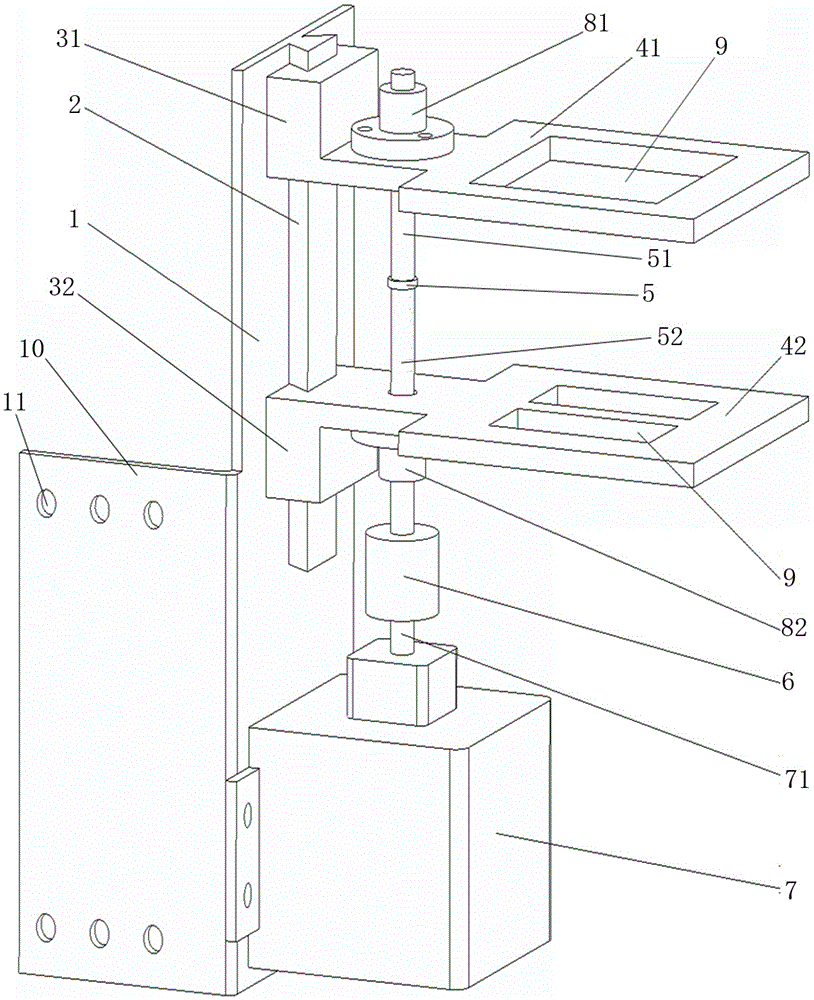

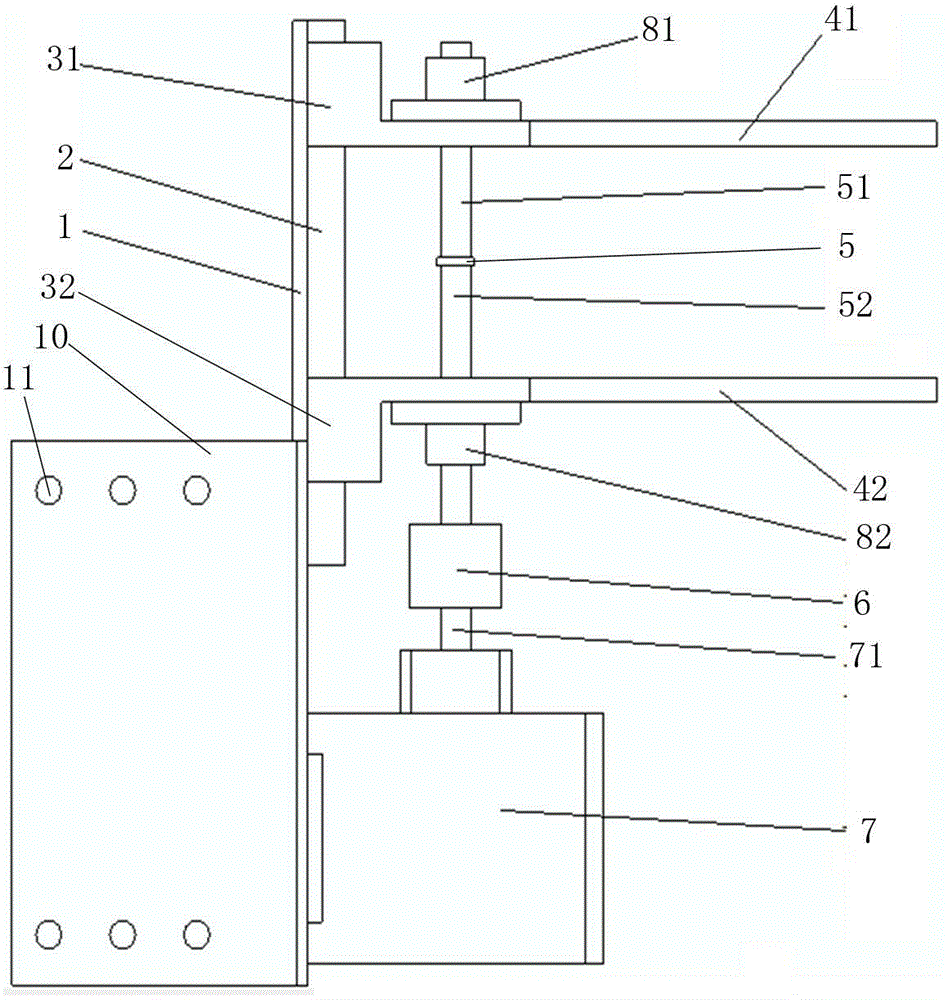

[0021] Please refer to figure 1 and figure 2 , this embodiment provides a screw electric clamp, which is characterized in that it includes a fixed plate 1, a slide rail 2 is arranged on one side of the fixed plate 1, and a corresponding Coordinated upper slider 31 and lower slider 32, the slide rail 2 and the chute of the upper and lower sliders are all dovetail-shaped structures, ensuring that the slide rail 2 is closely matched with the upper slider 31 and lower slider 32, and is not easy to fall off , the upper slider 31 is connected with an upper splint 41, preferably, the upper slider 31 is integrally formed with the upper splint 41, and the lower slider 32 is connected with the lower splint 42, preferably, the The lower slider 32 is integrally formed with the lower splint 42, the upper splint 41 and the lower splint 42 are connected through a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com