Flaw detection assisting collector

A collector and storage technology, used in tool storage devices, manufacturing tools, etc., can solve the problems of being scattered, difficult to find, and nowhere to place, and achieve the effect of easy ordering, easy finding and use, and reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, further elaborate the present invention.

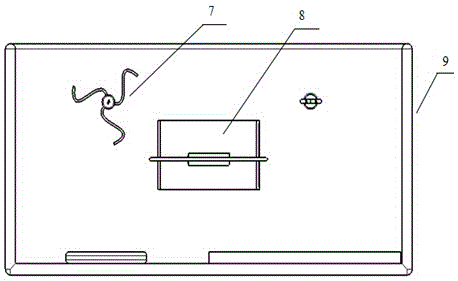

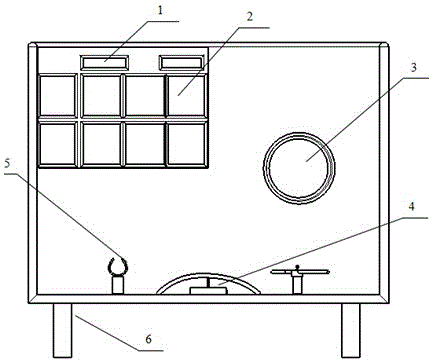

[0013] Such as figure 1 , shown in 2, a flaw detection auxiliary collector, including chalk storage room 1, lead type storage room 2, tape measure storage room 3, strong magnet 4, marker pen holder 5, auxiliary collector boss 6, soft tape measure collector 7. Magnetic shielding baffle 8. Storage shell 9.

[0014] A chalk storage room 1, a lead type storage room 2 and a tape measure storage room 3 are installed on the inner plane of the storage housing 9, and a marker pen holder 5, a soft tape measure collector 7 and a magnetic shielding baffle plate 8 side are installed on the side. Powerful magnet 4, auxiliary collector boss 6 is installed on the outside of storage shell 9.

[0015] The magnetic shielding baffle is made of two pieces of 0.6mm soft iron sheets on the outside and foam cotton in the middle.

[0016] When performing X-ray flaw detection work, you can put marker pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com