3d printing equipment and effectors of 3d printing equipment

A printing device and 3D printing technology, applied in the field of 3D printing, can solve the problems of non-concentrated cooling airflow, untimely cooling of models, and small effective printing range of 3D printing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

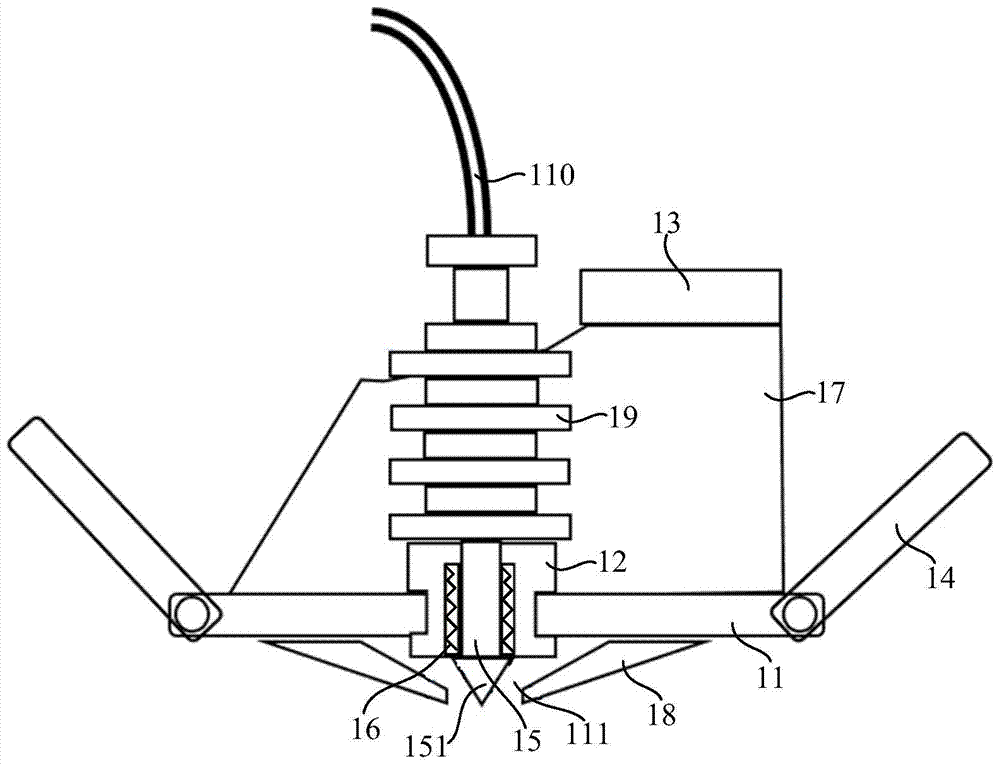

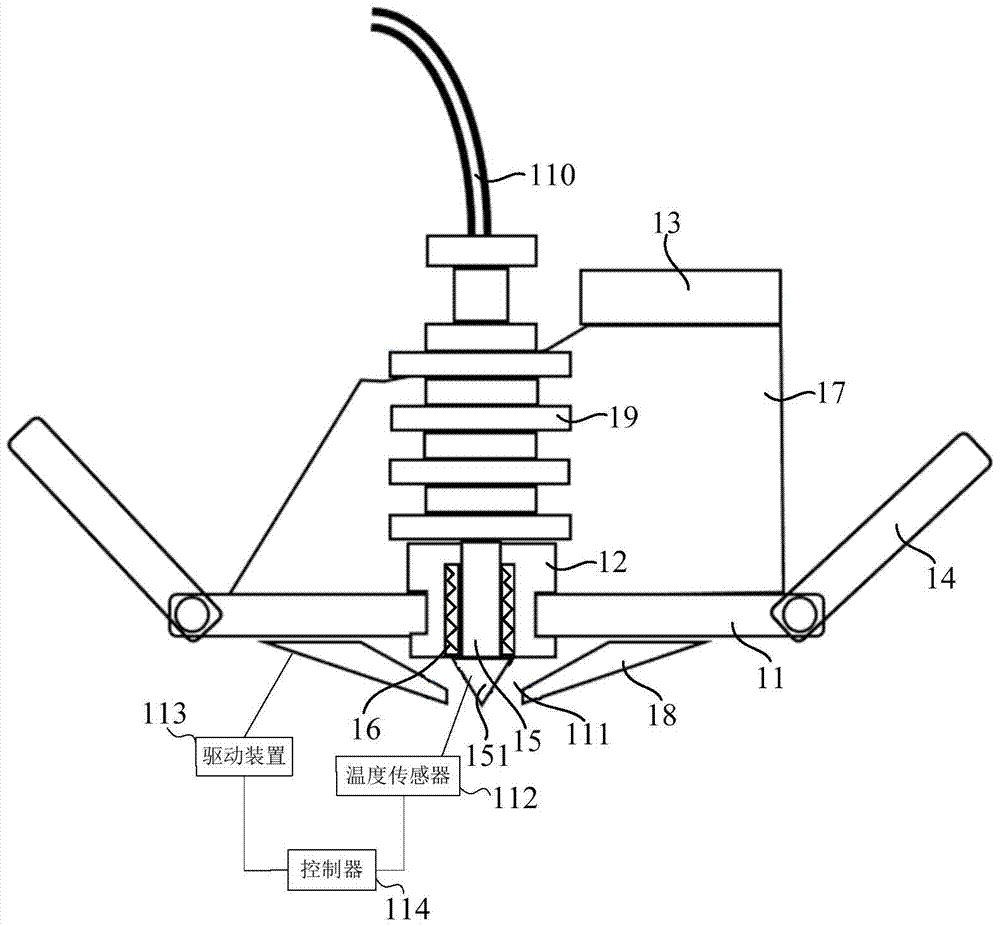

[0034] An embodiment of the present invention provides an effector for a 3D printing device, which solves the problems in the background art that the partial cooling of the model is not timely due to the lack of concentration of the cooling airflow, and the effective printing range of the 3D printing device is small.

[0035] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are described below in conjunction with the accompanying drawings The program is described in further detail.

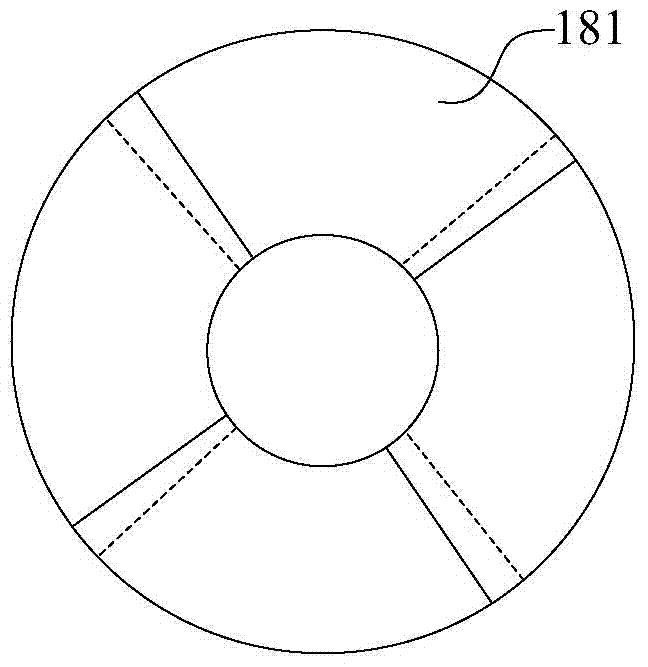

[0036] Please refer to the attached figure 1 , the embodiment of the present invention provides an effector of a 3D printing device. The provided effector of the 3D printing equipment includes an effector ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com