Tentering setting machine control system

A tenter setting machine and control system technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of unstable setting quality, tension and running line speed not well detected and controlled, etc. , to achieve the effect of improving the styling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

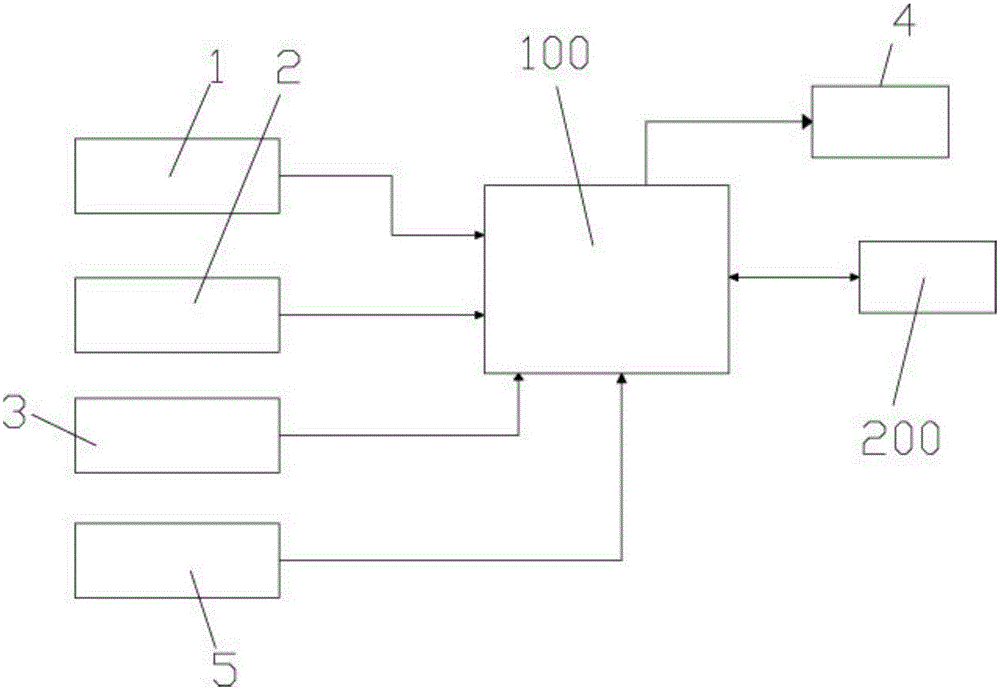

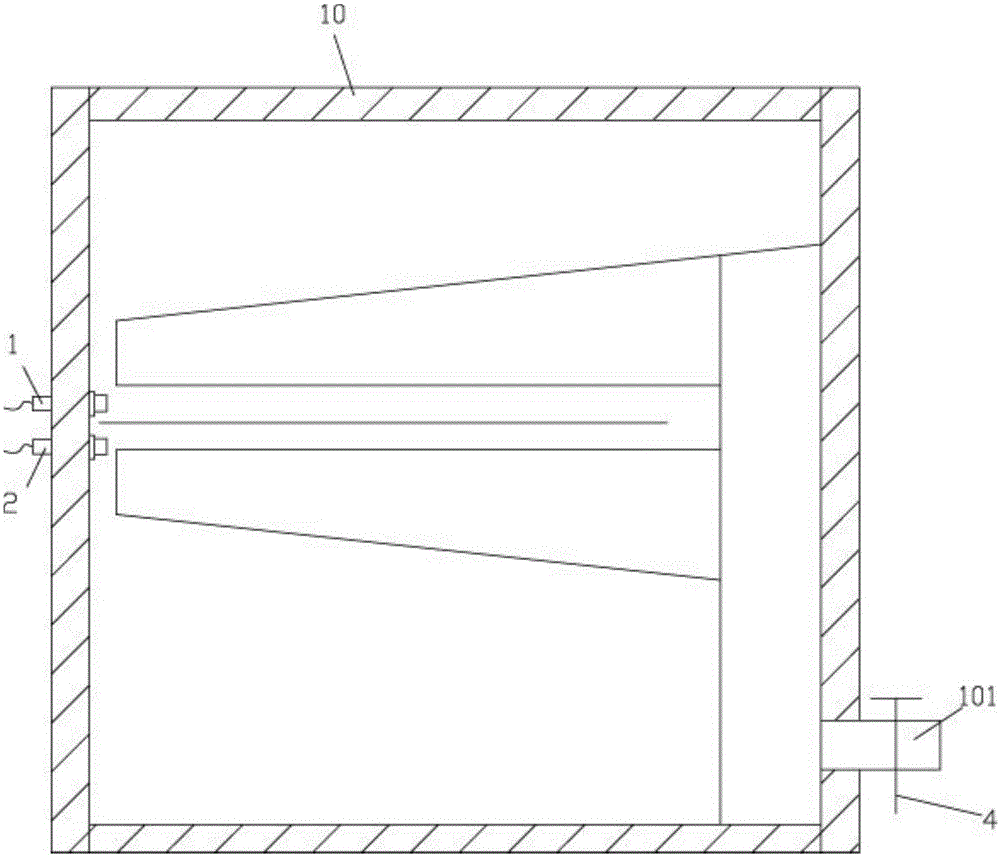

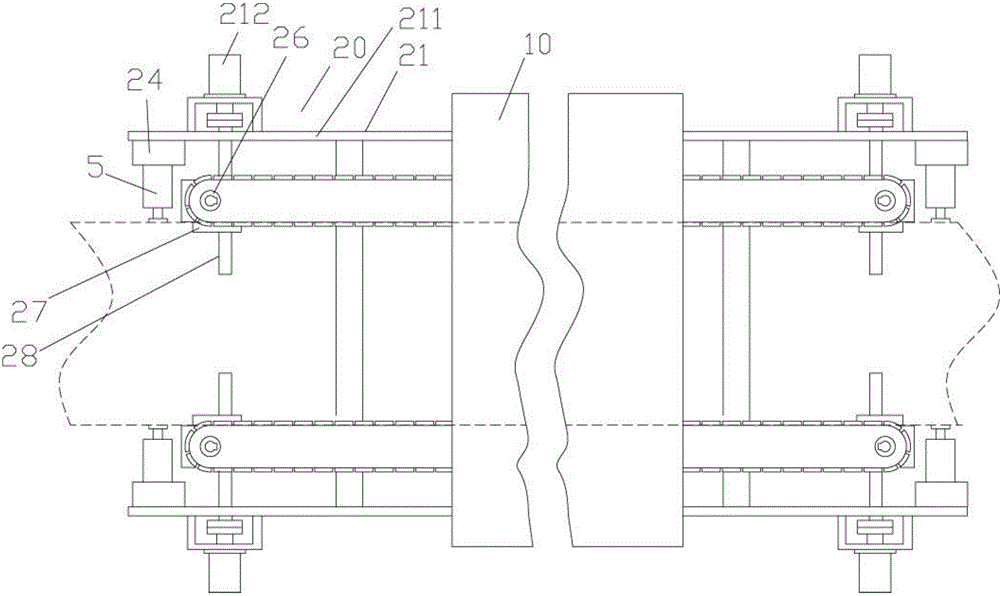

[0019] Examples, see e.g. Figures 1 to 5 As shown, a control system of a stenter setting machine includes a stenter body and a PLC control main board 100, each oven 10 of the stenter body is provided with a temperature sensor 1 and a humidity sensor 2, and a transmission device 20 of the stenter A vehicle speed sensor 3 is fixed on the frame 21 of the vehicle speed sensor 3, and the induction head of the vehicle speed sensor 3 faces the induction gear 23 fixed on the drive roller 22, and the air intake pipe 101 of the oven 10 is provided with a valve 4, and the temperature sensor 1 and the humidity sensor 2 will The sensing signal is sent to the PLC control board 100, and the PLC control board 100 processes the received sensing signal and controls the opening and closing of the corresponding valve 4;

[0020] The vehicle speed sensor 3 sends the induction signal to the PLC control main board 100, and the PLC control main board 100 processes the received induction signal and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com