Multi-disc Vacuum Washer

A multi-disk, pulp washer technology, applied in the direction of washing/replacing pulp treatment liquid, etc., can solve the problems that the production capacity is difficult to meet the production needs, the equipment is large in size, and the manufacturing difficulty is large, so as to achieve compact structure, reduce equipment investment, The effect of reduced infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solutions of the present invention, and do not constitute any form of limitation to the present invention.

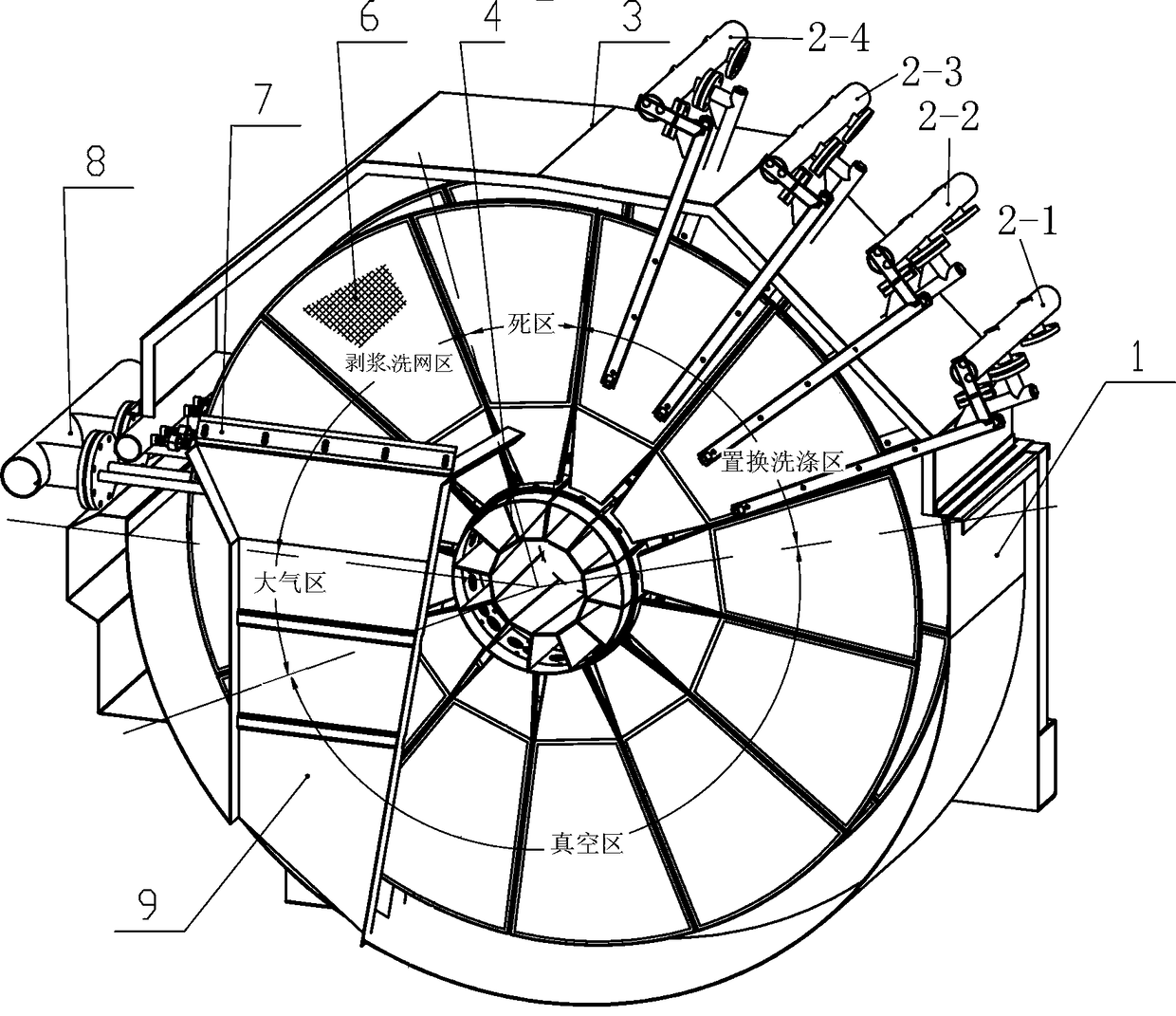

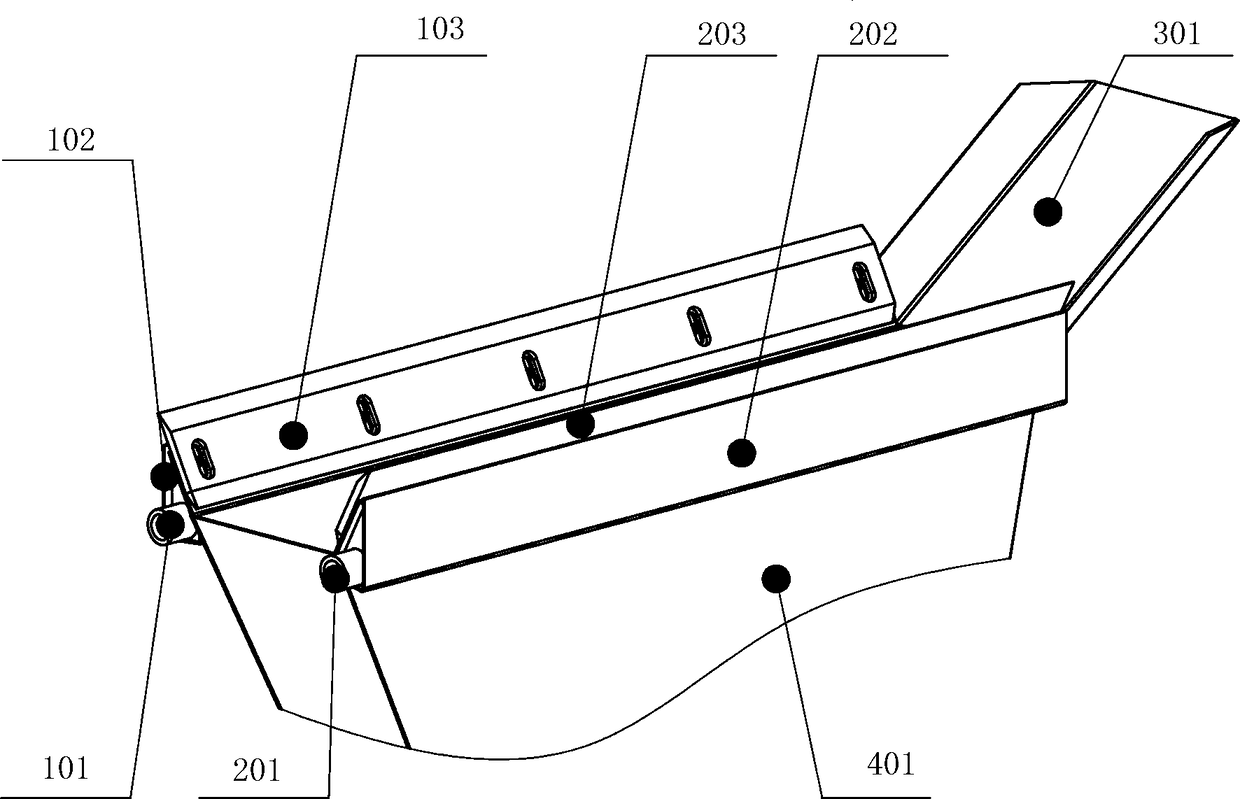

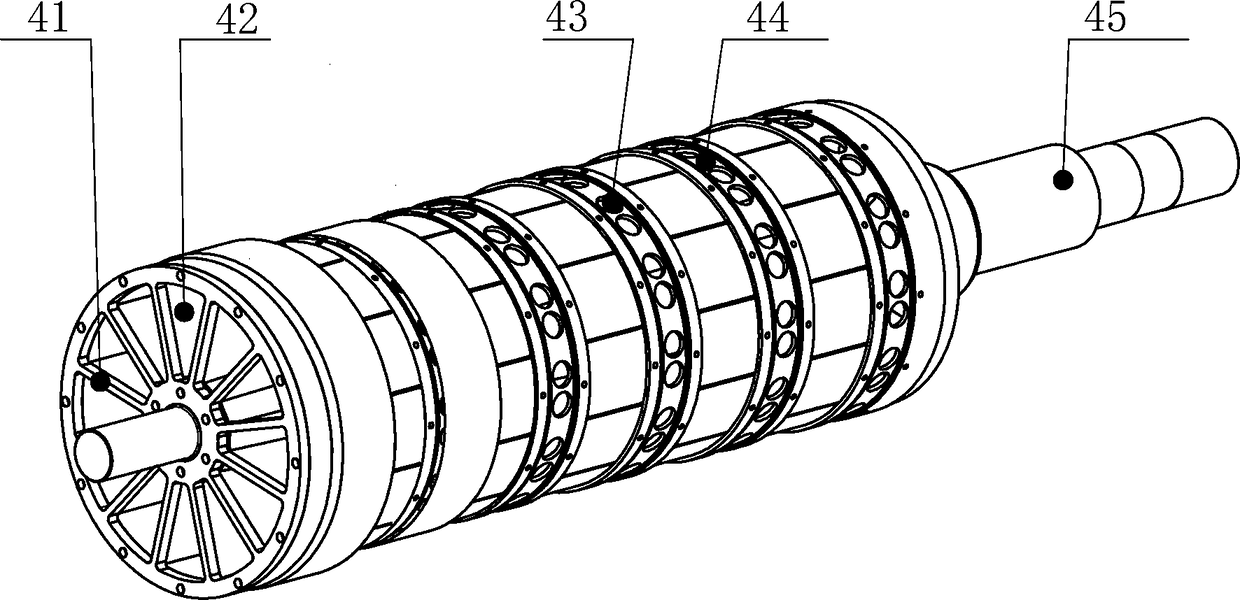

[0011] The multi-disc vacuum washing machine includes a tank body, in which there are multiple filter discs connected to the main shaft and parallel to each other. Each filter disc is composed of multiple independent fan-shaped plates, and the fan-shaped plates are hollow. The surface of the fan-shaped plate is provided with a filter screen, and a frame can be arranged on the fan-shaped plate, the filter screen is connected to the frame, the main shaft is a hollow structure, and the hollow structure of the main shaft is divided into a plurality of independent channels, and each channel is connected to the A fan-shaped plate of each filter disc is connected, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com