Sediment disposal system for water inlets of power station

A water inlet and power station technology, applied in hydropower stations, water conservancy projects, hydropower, etc., can solve the problems of small flow capacity of sand-drawing holes, small range of scour funnels, and small flow velocity at the mouth, etc., and achieve a significant effect of sand removal , Convenient construction and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

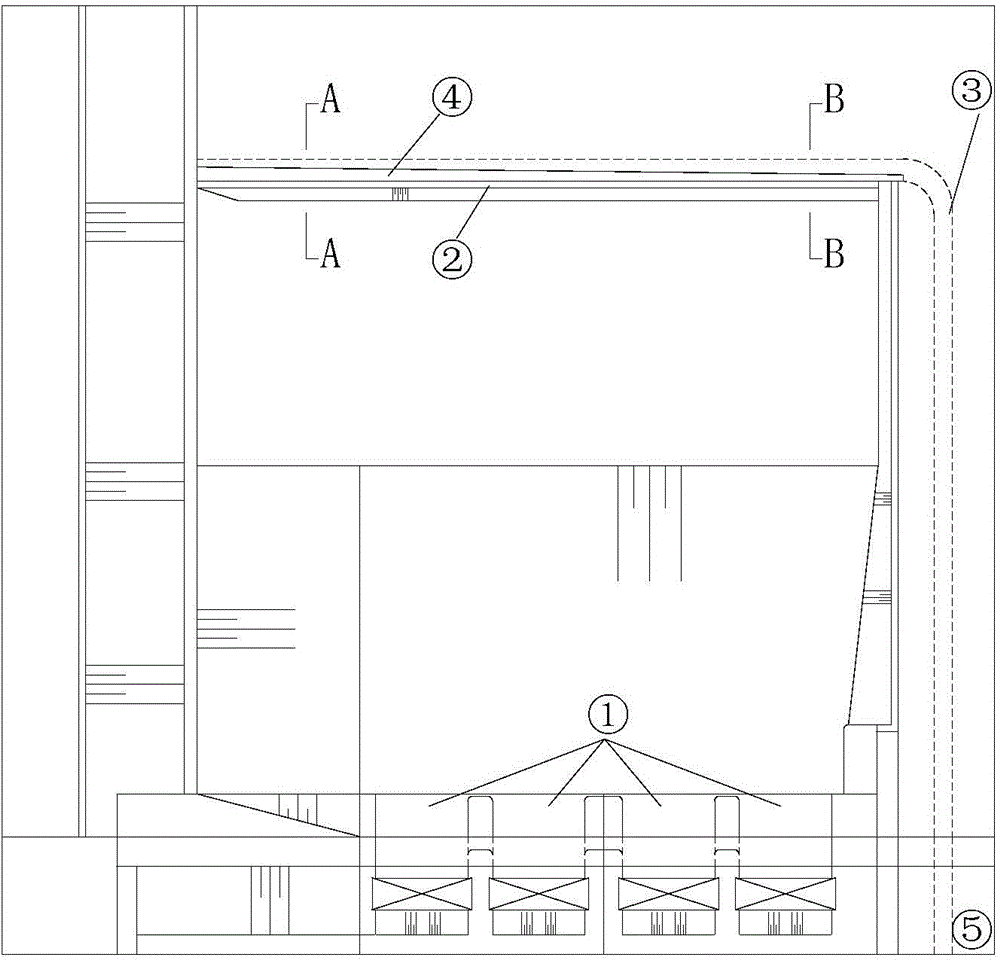

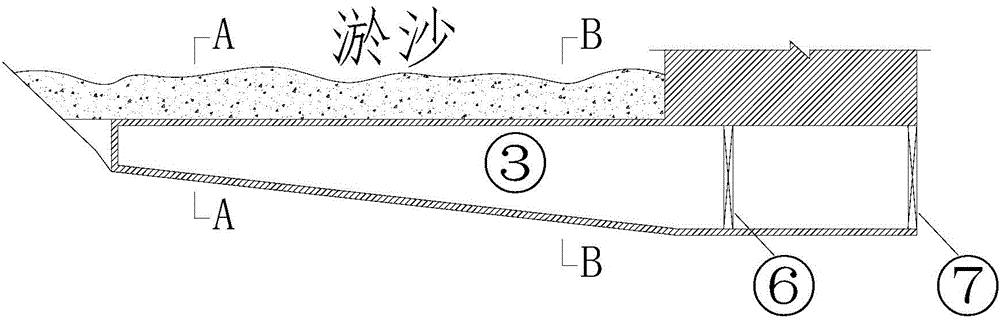

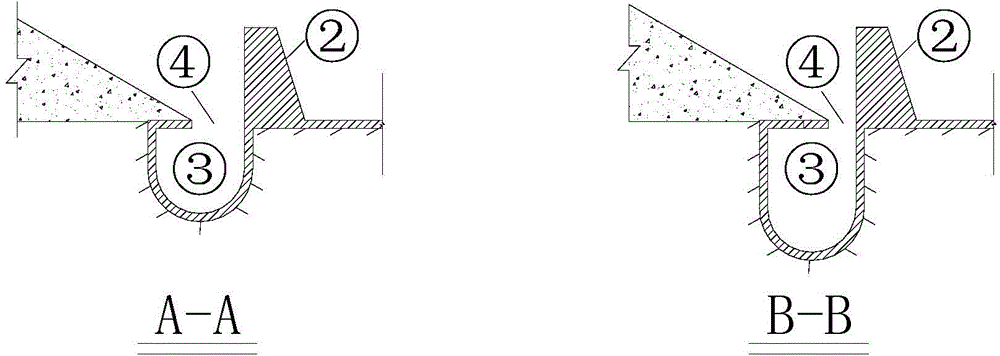

[0014] Below in conjunction with embodiment and attached Figure 1-3 The present invention is described further:

[0015] The sand discharge system of the power station water inlet of the present invention includes a sand retaining ridge 2, a sand delivery corridor 3 and a dam foundation sand discharge hole 5, and the dam foundation sand discharge hole 5 is arranged on the right side of the power station water inlet 1, and the The sand discharge tunnel 5 of the dam foundation is provided with a sand discharge tunnel maintenance door 6 and a sand discharge tunnel working door 7; The sand delivery corridor 3, the sand delivery corridor 3 is connected to the dam foundation sand discharge hole 5, and a horizontal seam sand discharge port 4 is provided on the top of the sand conveyance corridor 3, and the horizontal seam sand discharge port The width of 4 gradually narrows from the upstream, and the cross-section of the sand delivery corridor 3 gradually increases from the upstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com