A sand discharge method for the water inlet of a low-head riverbed-type pivotal power station

A water inlet, low head technology, applied in the direction of hydropower station, hydropower, traditional hydropower energy, etc., can solve the problems of small flow capacity of lasha hole, small range of scouring funnel, small flow rate at the entrance, etc. The sand effect is obvious, the construction is convenient, and the water consumption is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

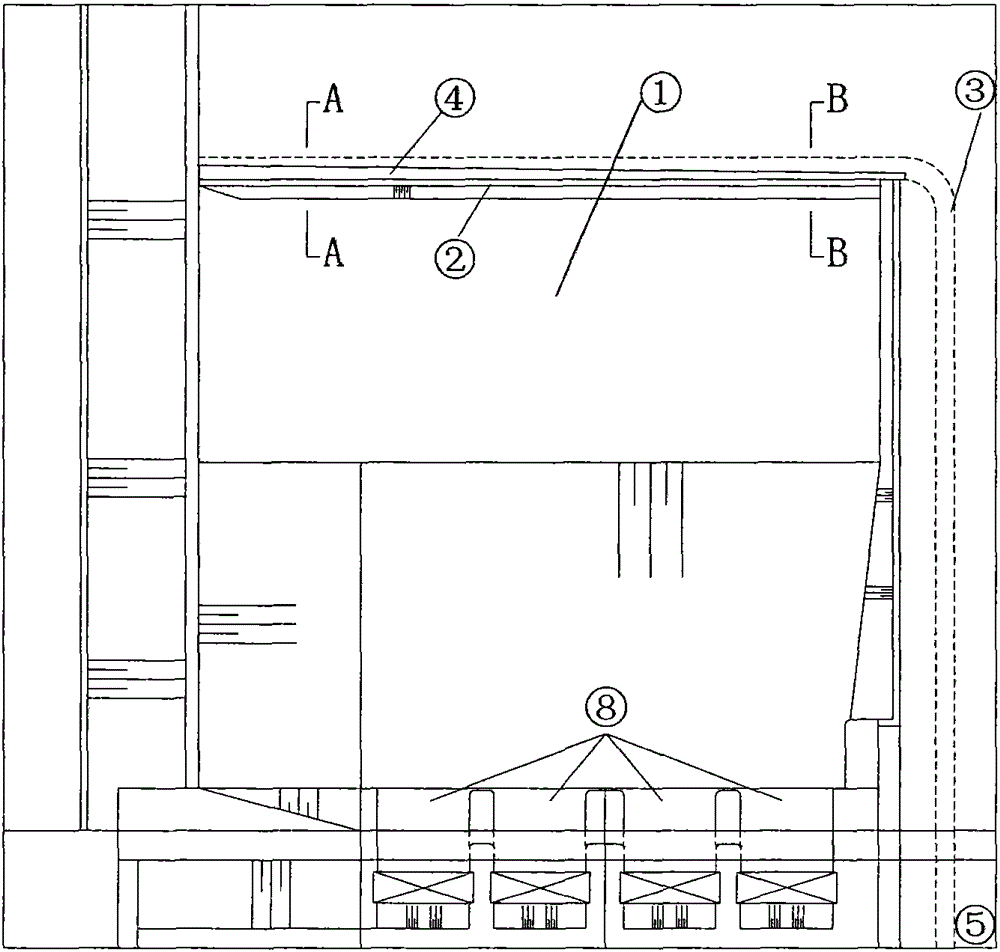

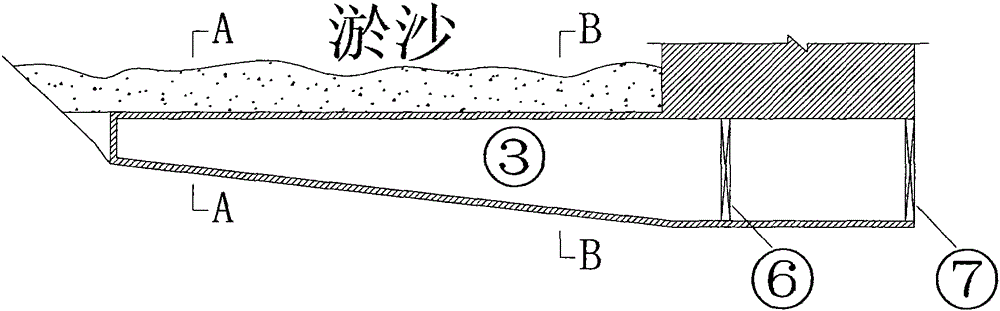

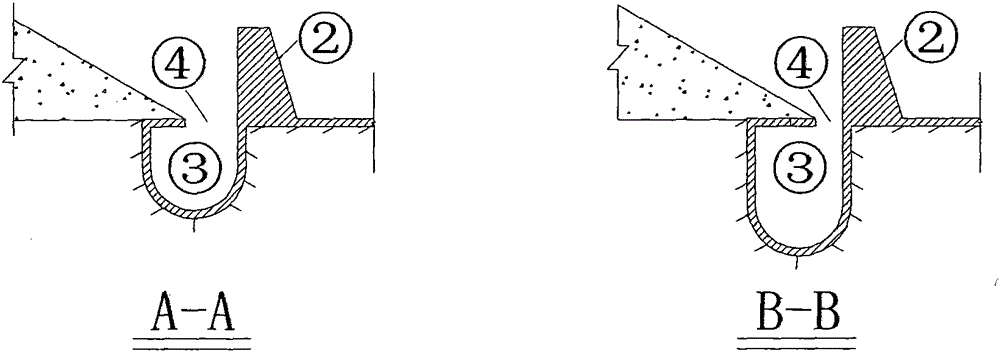

[0017] The following examples and attachments are combined Figure 1-3 To further explain the present invention:

[0018] The method for discharging sand at the water inlet of a low-head riverbed junction power station of the present invention includes building layout and operation modes:

[0019] (1) Building layout: a dam foundation sand discharge tunnel 5 is set on the right side of the power station water inlet 1, and the dam foundation sand discharge tunnel 5 is provided with a sand discharge tunnel inspection door 6 and a sand discharge tunnel working door 7. A sand barrier 2 is arranged along the front edge of the water inlet 1 of the power station, and a sand conveyance corridor 3 is arranged in front of the sand barrier 2. The sand conveyance corridor 3 is connected to the dam foundation sand discharge tunnel 5. A horizontal seam sand discharge port 4 is provided on the top of the sand conveyance corridor 3, and the width of the horizontal seam sand discharge port 4 gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com