Sediment transport device

A technology for transporting and discharging sand, which is used in hydropower stations, marine engineering, coastline protection, etc. It can solve the problems of easy silting in corridors, small sand removal range, and long front edge of water inlets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

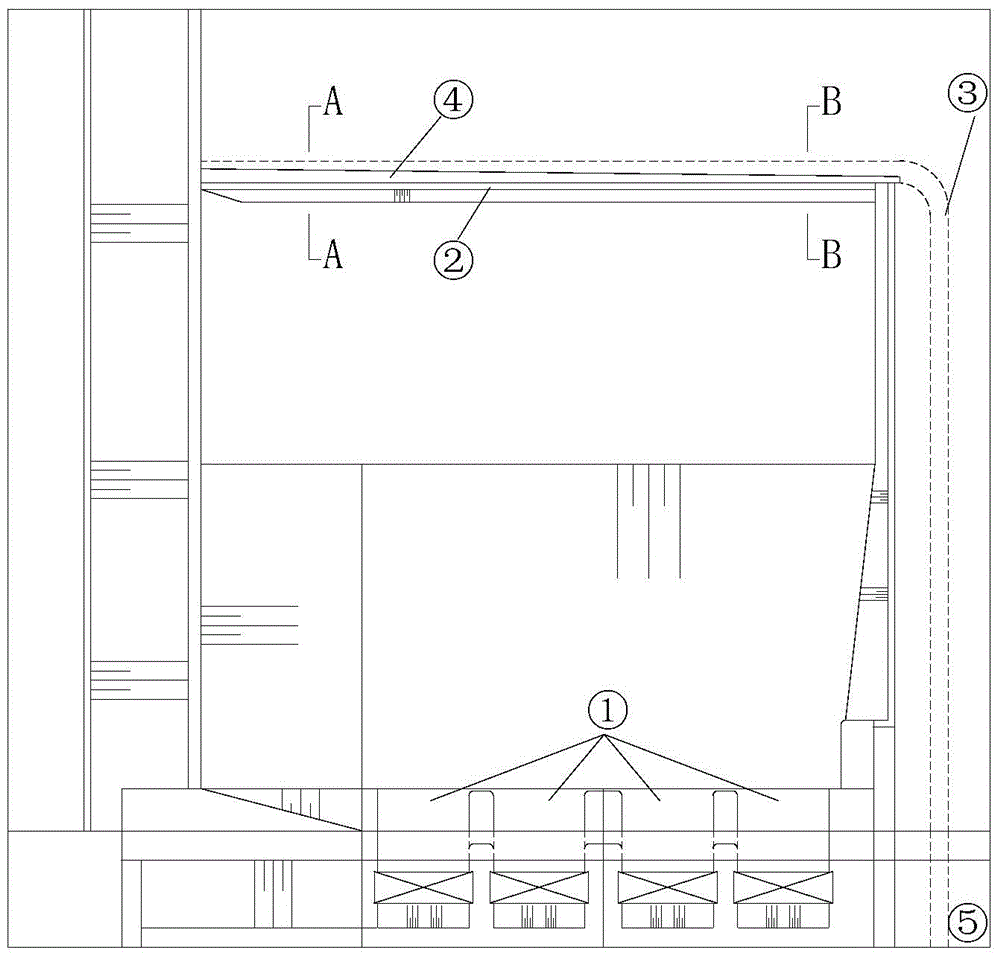

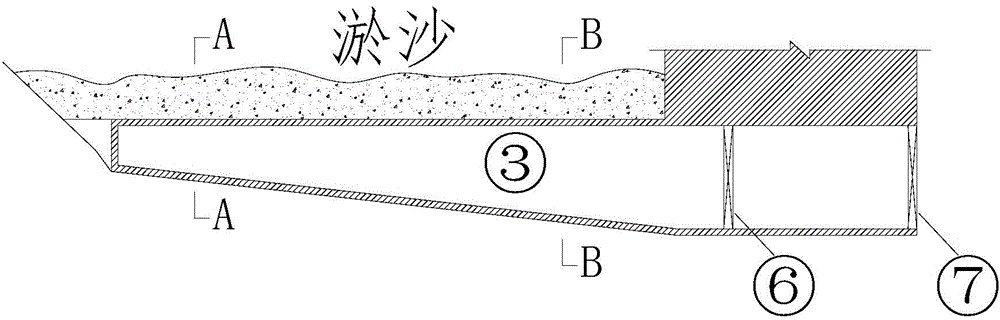

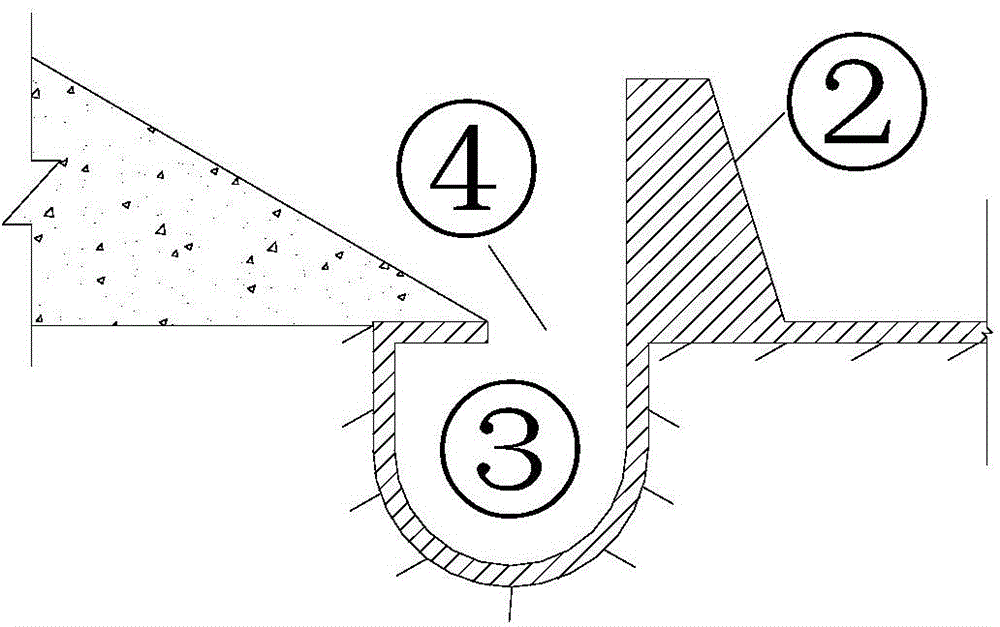

[0011] Below in conjunction with embodiment and attached Figure 1-3 The present invention is described further:

[0012] A sand transport device, comprising a sand retaining ridge 2, a sand transport corridor 3 and a dam foundation sand discharge tunnel 5, the dam foundation sand discharge tunnel 5 is arranged on the right side of the water inlet 1 of the power station, and the dam foundation sand discharge tunnel 5 is provided with There are inspection doors 6 and working doors 7 for the sand discharge tunnel; the sand barrier 2 is set at the front edge of the water inlet 1 of the power station, and the sand transport corridor 3 is set in front of the sand barrier 2. The sand delivery corridor 3 is connected with the sand discharge hole 5 of the dam foundation, and a horizontal seam sand discharge outlet 4 is provided on the top of the sand transportation corridor 3, and the width of the horizontal seam sand discharge outlet 4 gradually narrows from the upstream, The cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com