Semi-automatic water pump performance test platform

A water pump performance and test platform technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as multiple equipment specifications, electrical failures, height and dimension changes, etc., to avoid electrical failures and solve vibration problems , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

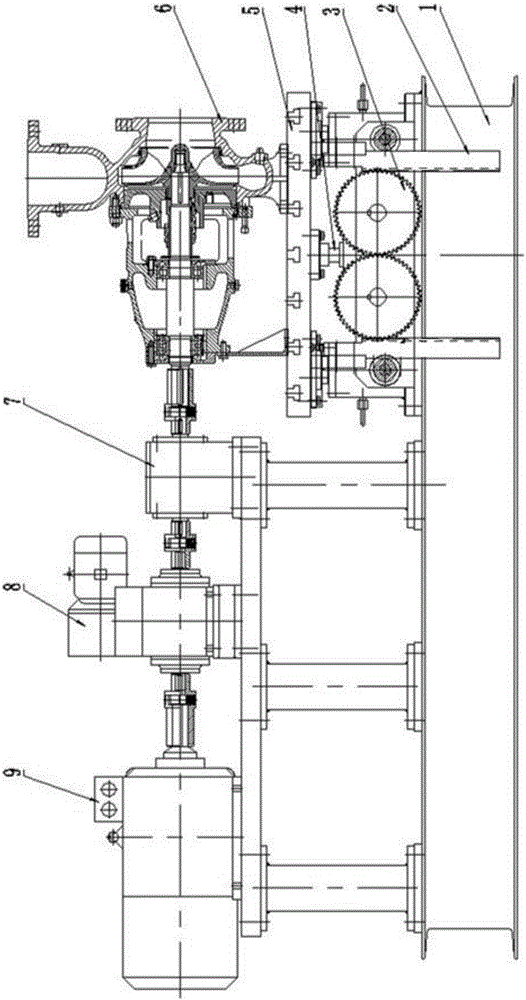

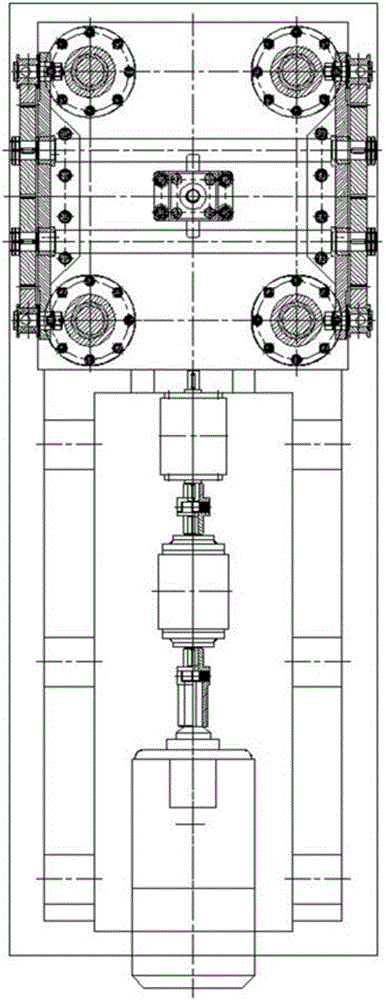

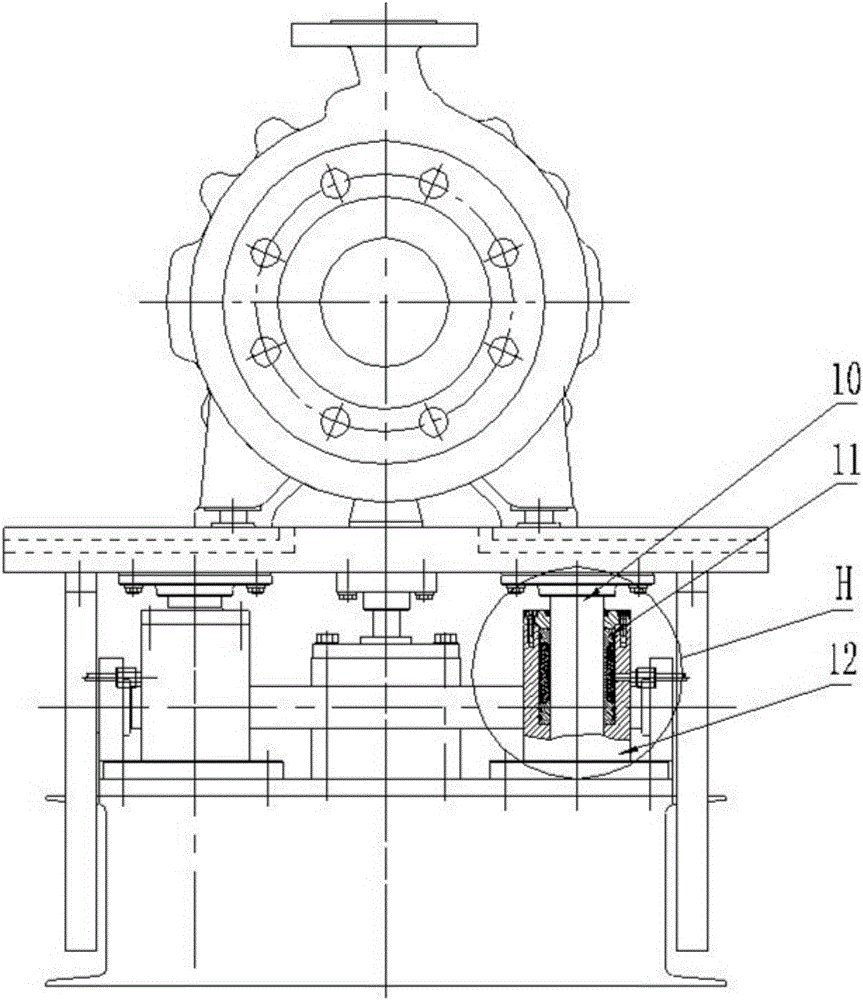

[0021] Such as Figure 1-Figure 5 As shown, the semi-automatic water pump performance test platform includes a base 1, a platform 5, a water pump 6, and a motor 9. The water pump 6 is installed on the platform 5, and the motor 9 is installed on the base 1. It also includes a rack 2, a gear 3, and an oil cylinder 4. Torque meter 8, guide post 10, thin-walled sleeve 11, support sleeve 12 and pressurized oil cylinder, four racks 2 are fixed around the bottom of platform 5 and are located on both sides of base 1 in pairs, between the racks 2 on each side There are two gears 3 meshed between them. The gears 3 are used to prevent the platform 5 from tilting, so that the racks 2 can rise and fall at the same time. A gear shaft is installed between the opposite gears 3 on both sides. Adjusting bolts are provided on each rack 2. First adjust the positions of the two gears 3, then adjust the positions of the two racks 2, and tighten the adjusting bolts to ensure the meshing gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com