Hydrostatic drive system to regulate demand flow

A technology for hydrostatic drive and adjustment requirements, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve problems such as power loss of unloading valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

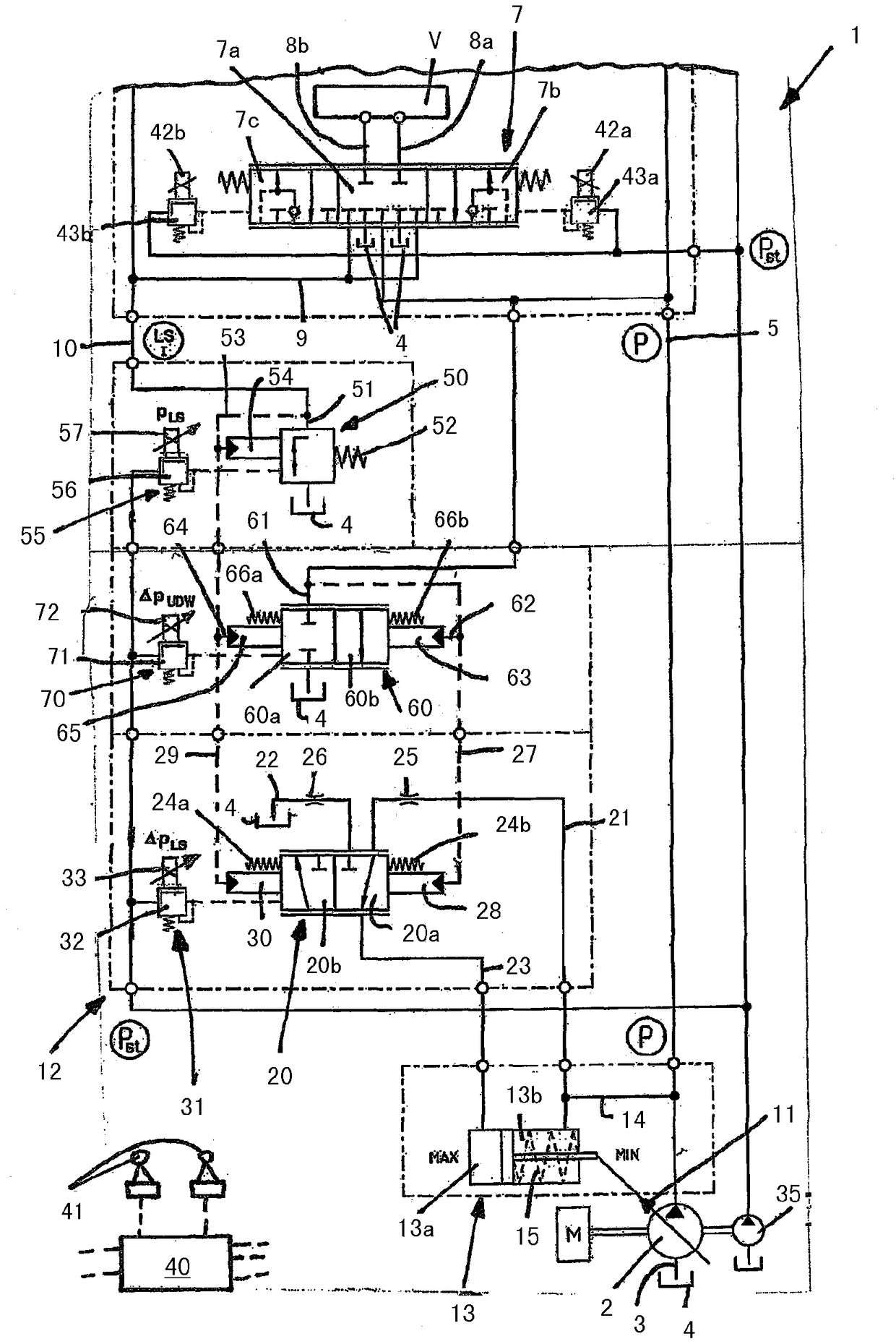

[0033] The pump 2 is designed as a pump whose delivery volume can be adjusted steplessly, which operates in an open circuit and can be unilaterally switched between the position "MIN" with the minimum delivery volume and the position "MIN" with the maximum delivery volume with respect to the delivery volume. MAX” to adjust. The pump 2 is connected with a line 3 to a container 4 for sucking in the pressure medium and feeds it into a delivery line 5 . In order to control the direction of movement and the speed of movement, a control valve 7 is provided for each consumer V of the hydrostatic drive system 1 , which is designed as a directional control valve that throttles in the middle position. Only one control valve 7 for one consumer V is shown in the drawing. Of course, other control valves 7 can be similarly provided for other consumers V.

[0034] The control valve 7 shown in the drawing is connected to the delivery line 5 , the container 4 and the pressure medium lines 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com