Vertical gyro tester

A tester and gyro technology, applied in the field of avionics test, can solve problems such as failure to reproduce faults on the ground, vertical gyro function and detailed technical index testing, etc., to avoid repeated construction, avoid direct installation, and improve efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

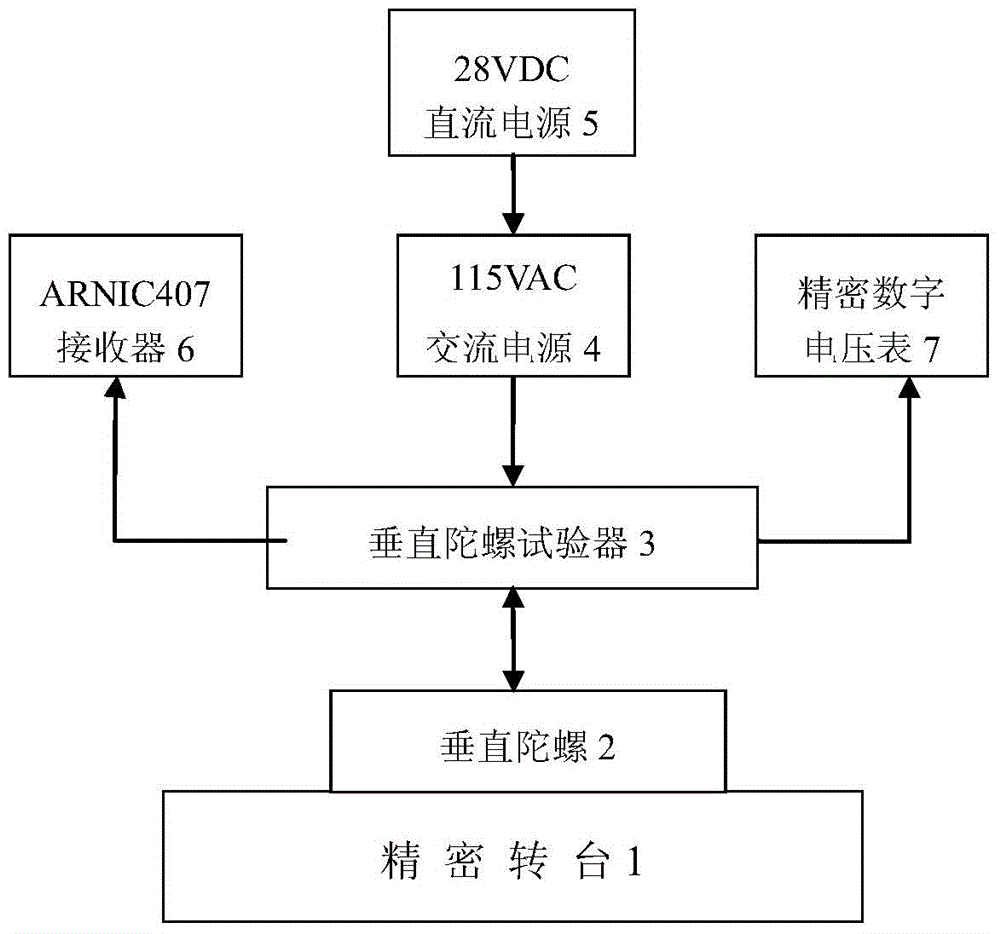

[0013] The present invention will be described in detail below by taking the 332D-11 vertical gyroscope as an example in conjunction with the accompanying drawings.

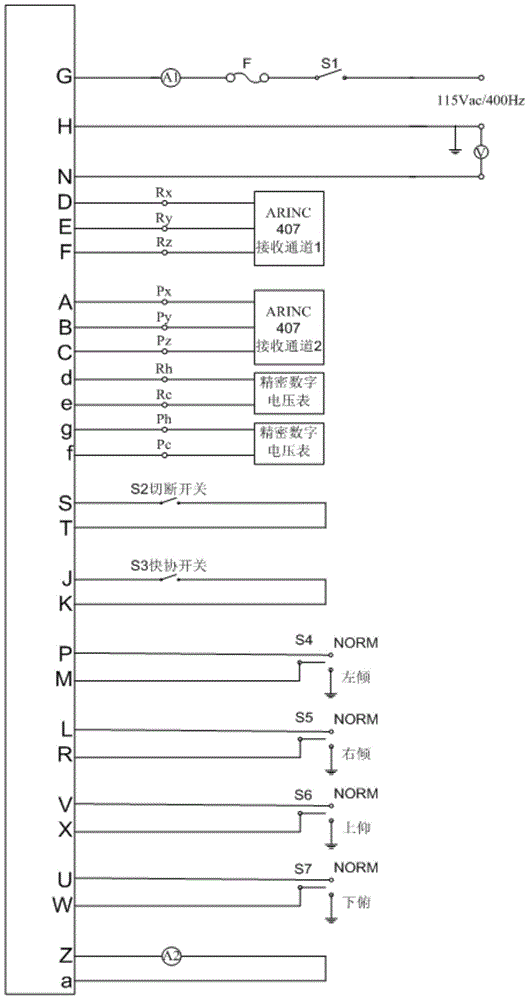

[0014] like figure 1 As shown, the vertical gyro tester is composed of a first single-pole single-throw switch S1, a cut-off switch S2, a fast association switch S3, a first single-pole double-throw switch S4, a second single-pole double-throw switch S5, a third single-pole double-throw switch S6, and a second single-pole double-throw switch S6. Four SPDT switches S7, fuse F, first ammeter A1, second ammeter A2, voltmeter V, test holes Rx, Ry, Rz, Px, Py, Pz, Rh, Rc, Ph, Pc.

[0015] The high end of the 115VAC, 400Hz AC power supply is connected to the power input terminal G of the vertical gyro plug through the SPDT switch S1 and the fuse F through the ammeter A1; the low end of the 115VAC, 400Hz AC power supply is connected to the ground H of the vertical gyro plug power supply; The gyro plug is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com