Measurement apparatus and method for minimum vacuum leak rate

A leak rate measurement and vacuum technology, applied in the measurement field, can solve problems such as large measurement uncertainty, large measurement uncertainty, and inability to complete measurement, and achieve the effect of eliminating outgassing effect and avoiding large measurement uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

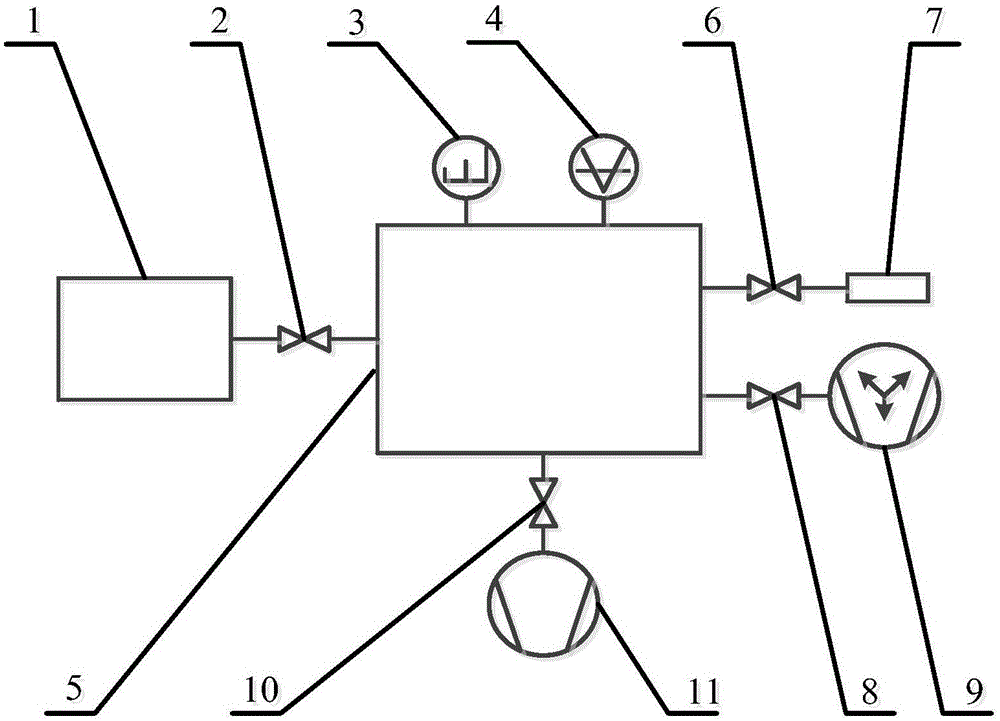

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

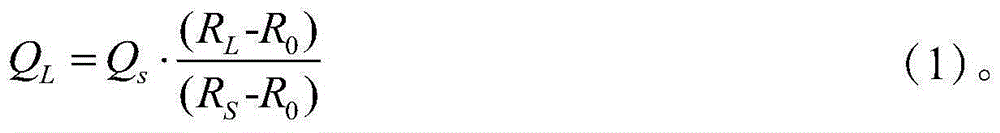

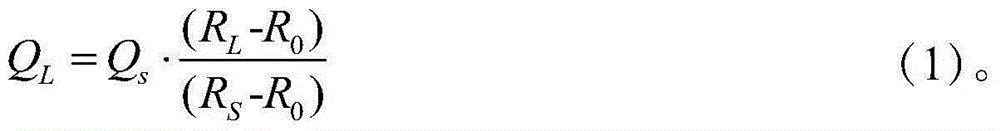

[0029] The idea of the present invention is: considering that it is difficult to identify the ion flow of the hole to be corrected from the background, the present invention finds a new way to use the rate of increase of the ion flow for processing. Specifically, the background pressure is maintained by baking and continuous pumping, so that the increase rate of the background ion current is very small, and it is basically a constant value, which is convenient for measurement. And considering that the order of magnitude of the ion current rise rate of the hole to be checked and the background is very different, it is possible to obtain the rate of rise of the ion current containing the background and the hole to be checked by measuring, and subtract the known background from the data The fixed value of the ion current rising rate can obtain the ion curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com