Device and method for calibrating vacuum gauge for work

A technology of a calibration device and a calibration method, applied in the field of measurement, can solve the problems of increased calibration uncertainty, inability to achieve, and low accuracy of a vacuum gauge, and achieve the effect of reducing measurement uncertainty and improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

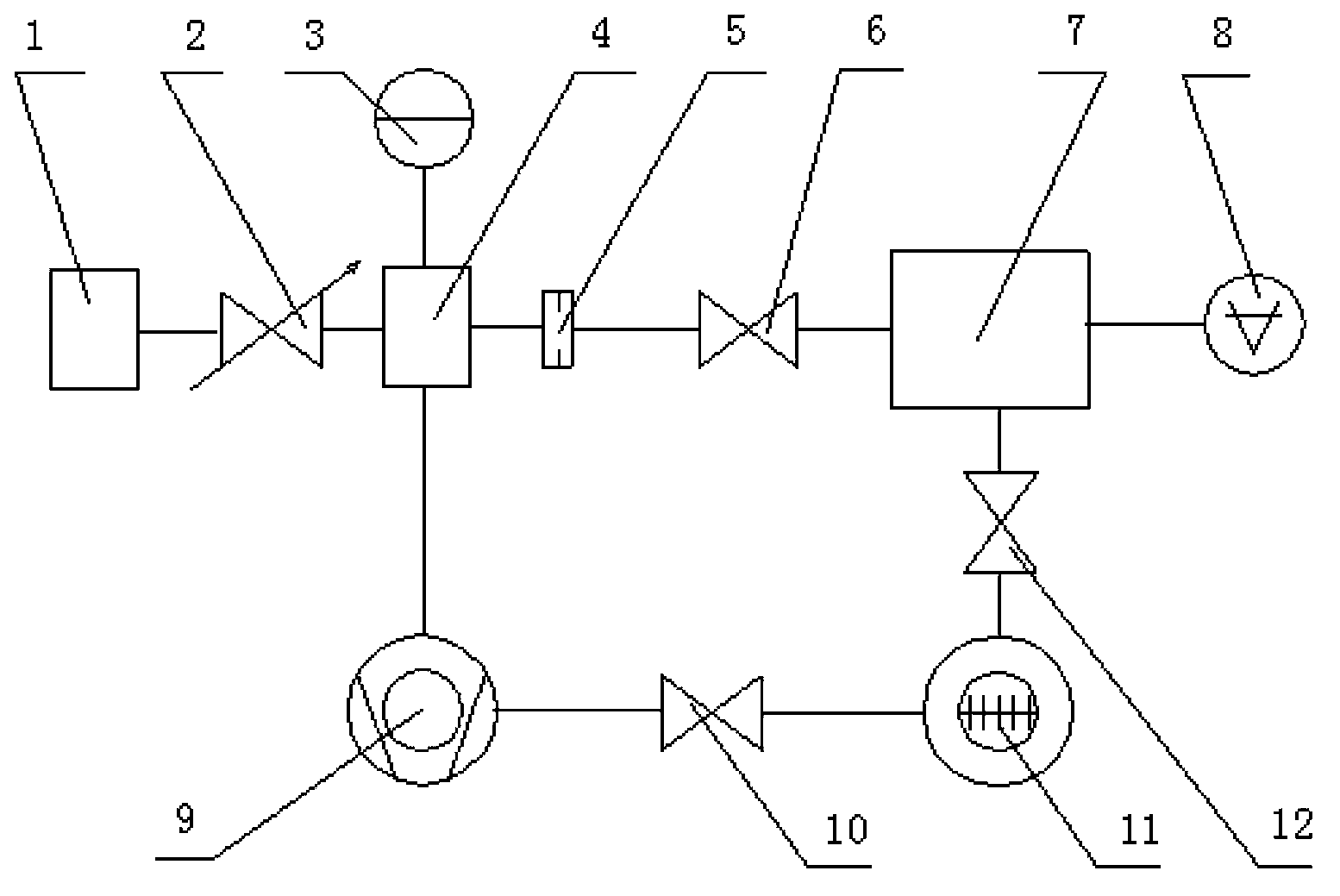

[0028] Such as figure 1 As shown, a working vacuum gauge 8 calibration device, said device includes: gas supply system 1, fine-tuning valve 2, standard vacuum gauge 3, standard container 4, small hole 5, bellows stop valve 6, calibration chamber 7, Working vacuum gauge 8, mechanical pump 9, isolation valve 10, molecular pump 11, all metal flapper valve 12;

[0029] Gas supply system 1, fine-tuning valve 2, standard container 4, small hole 5, bellows stop valve 6, calibration chamber 7, working vacuum gauge 8 are connected in sequence, standard vacuum gauge 3 is connected to standard container 4, mechanical pump 9 is connected to standard The container 4 is connected, the molecular pump 11 is connected with the calibration chamber 7 through the all-metal flapper valve 12, one end of the isolation valve 10 is connected with the mechanical pump 9, and the other end is connected with the molecular pump 11;

[0030] Among them, the gas supply system 1 is a gas cylinder or an air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com