Static sampling introduction device and method of calibrating pressure leak hole

A positive pressure leak and calibration device technology, applied in the field of measurement, can solve the problems of low helium partial pressure, long accumulation time, large measurement uncertainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

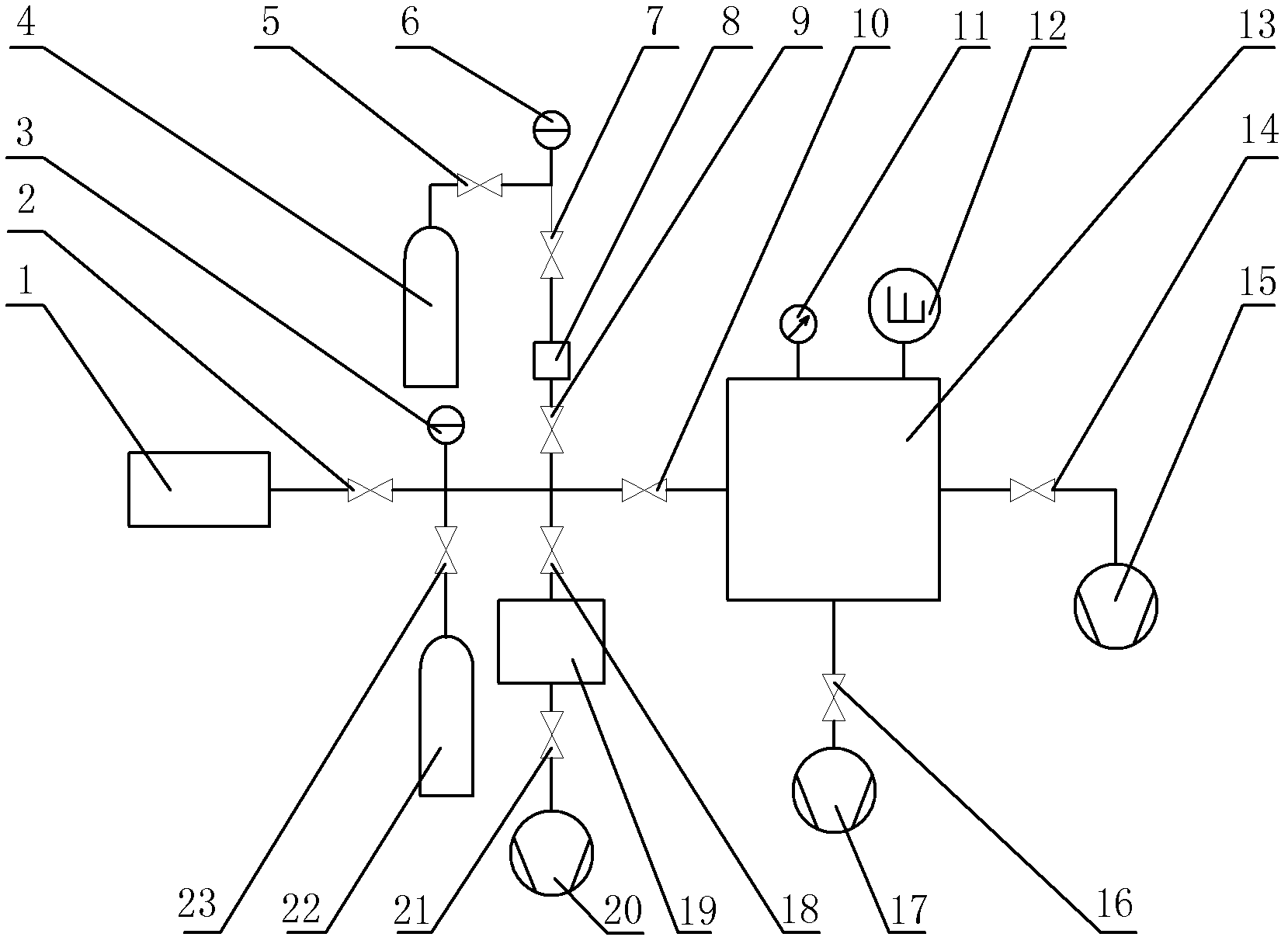

[0041] Such as figure 1 As shown, a positive pressure leak calibration device for static sampling, said device includes: calibrated leak hole 1, valve one 2, capacitance film gauge one 3, helium cylinder 4, valve two 5, capacitance film gauge two 6. Valve three 7, standard volume one 8, valve four 9, valve five 10, monitoring gauge 11, quadrupole mass spectrometer 12, calibration chamber 13, valve six 14, getter pump 15, valve seven 16, molecular pumping Gas unit one 17, valve eight 18, standard volume two 19, molecular pump exhaust unit two 20, valve nine 21, nitrogen cylinder 22, valve ten 23.

[0042] Among them, the calibrated leak hole 1 is connected to the calibration chamber 13 through the valve one 2 and the valve five 10; Atmospheric pressure dry nitrogen is provided at the outlet; capacitive film gauge 13 is connected with valve 12 and valve 1023 for measuring the pressure at the outlet of calibrated leak hole 1; helium cylinder 4 passes through valve 25 and valve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com