Device for testing comprehensive performance of round wire concentric lay overhead electrical stranded conductor

A technology for comprehensive performance testing and overhead wires, applied to measuring devices, using stable tension/pressure to test material strength, measuring electrical variables, etc., can solve the problems of wasting wires, low efficiency, poor precision, etc., and achieve saving wires, Check the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

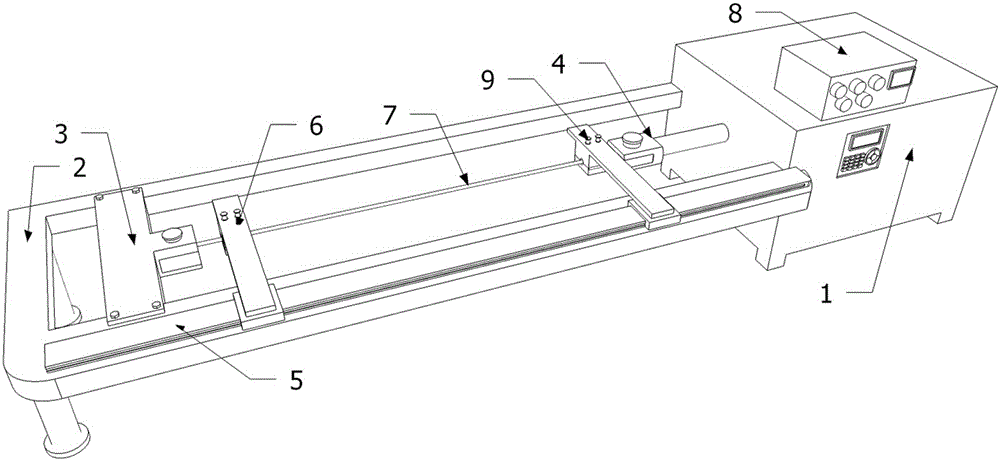

[0019] see figure 1 , a round wire concentric stranded overhead conductor comprehensive performance testing device, including a horizontal tensile testing machine and a conductor direct current resistance testing device.

[0020] The horizontal tensile testing machine includes a main machine 1, a truss 2, a beam 3 and a jaw joint; one side of the truss 2 is provided with a guide rail 5; the beam 3 is fixed on the truss 2 and is perpendicular to the guide rail 5; the jaw joint includes a beam jaw joint And the proximal jaw joint 4, the beam jaw joint is fixed on the middle part of the beam 3, and the proximal jaw joint 4 is fixedly connected to the piston of the host machine 1.

[0021] The conductor DC resistance testing device includes a bridge main unit 8 and two bridge test arms 6 .

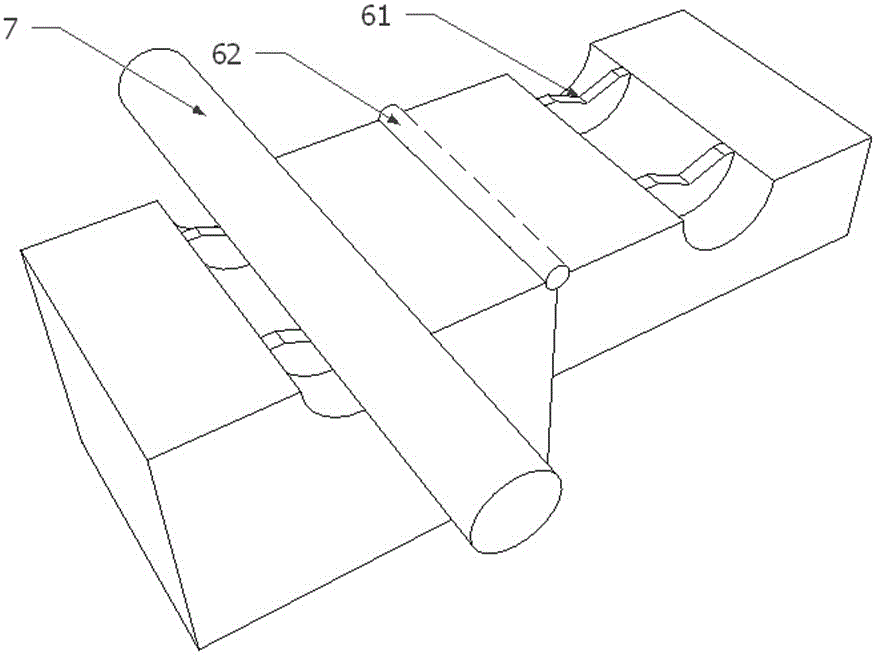

[0022] The improvement is that one end of the bridge tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com