Safety protecting system for belt conveyor

A belt conveyor and safety protection technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of complex wiring, short transmission distance, easy to be interfered, etc., to reduce wires and anti-interference ability. Strong, interference-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

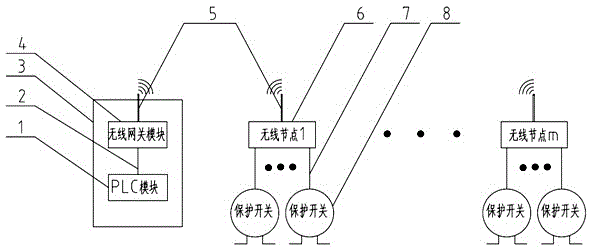

[0027] Such as figure 1 As shown, a belt conveyor safety protection system includes a control module and a signal acquisition module; the control module includes a PLC unit and a wireless gateway module connected to it; the signal acquisition module includes a deviation signal acquisition module and is connected to it The wireless signal transmitting antenna; when the belt deviates, the deviation signal acquisition module sends the deviation signal through the wireless signal transmitting antenna; the wireless gateway module receives the belt deviation signal sent by the wireless signal transmitting antenna.

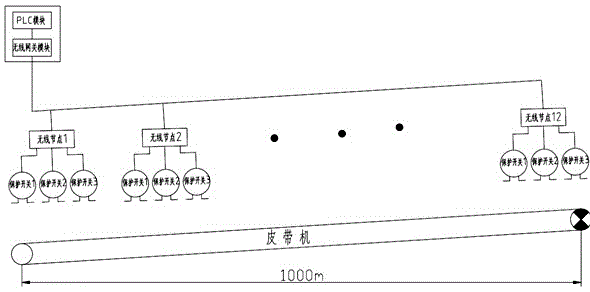

[0028] This specific embodiment is described in detail with a 1000-meter belt conveyor as an example, as figure 2 shown.

[0029] Each wireless signal transmitting antenna is a wireless node, and in this specific embodiment, each wireless node is equipped with a joint adapter line and a lightning protector. The power supply of wireless node and wireless gateway module...

specific Embodiment 2

[0035] The difference with Embodiment 1 is only that: on the basis of Embodiment 1, the signal acquisition module also includes an accident signal acquisition module. When an accident occurs and the accident signal acquisition module is triggered, the accident signal acquisition module will The accident signal is sent out through the wireless signal sending antenna; the wireless gateway module receives the accident signal sent by the wireless signal sending antenna.

[0036] The accident signal acquisition module is a pull rope switch, and every three to five pairs of pull rope switches define an accident address.

[0037] The pull rope switches are arranged in pairs on both sides of the belt, and a pair is arranged at intervals of 30 meters to 50 meters from one end of the belt to the other end. In this specific embodiment, a pair of pull rope switches is arranged every 30 meters along the belt conveyor, a total of 34 pairs. Define 3 pairs of pull rope switches as an address...

specific Embodiment 3

[0039] The difference with specific embodiment 1 and specific embodiment 2 is only that, in this specific embodiment, the signal acquisition module only includes the accident signal acquisition module, when an accident occurs and the accident signal acquisition module is triggered, the accident signal The acquisition module sends the accident signal through the wireless signal sending antenna; the wireless gateway module receives the accident signal sent by the wireless signal sending antenna. In this specific embodiment, a pair of pull rope switches is arranged every 30 meters along the belt conveyor, a total of 34 pairs. Define 3 pairs of pull rope switches as an address, and install 1 wireless node for address coding, a total of 12 wireless nodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com