A wet etching device

A technology of wet etching and resistive pressure, which is applied in the direction of displaying liquid level indicators through pressure measurement, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems of inaccurate detection results, wrong liquid level signals, and easy sticking housing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

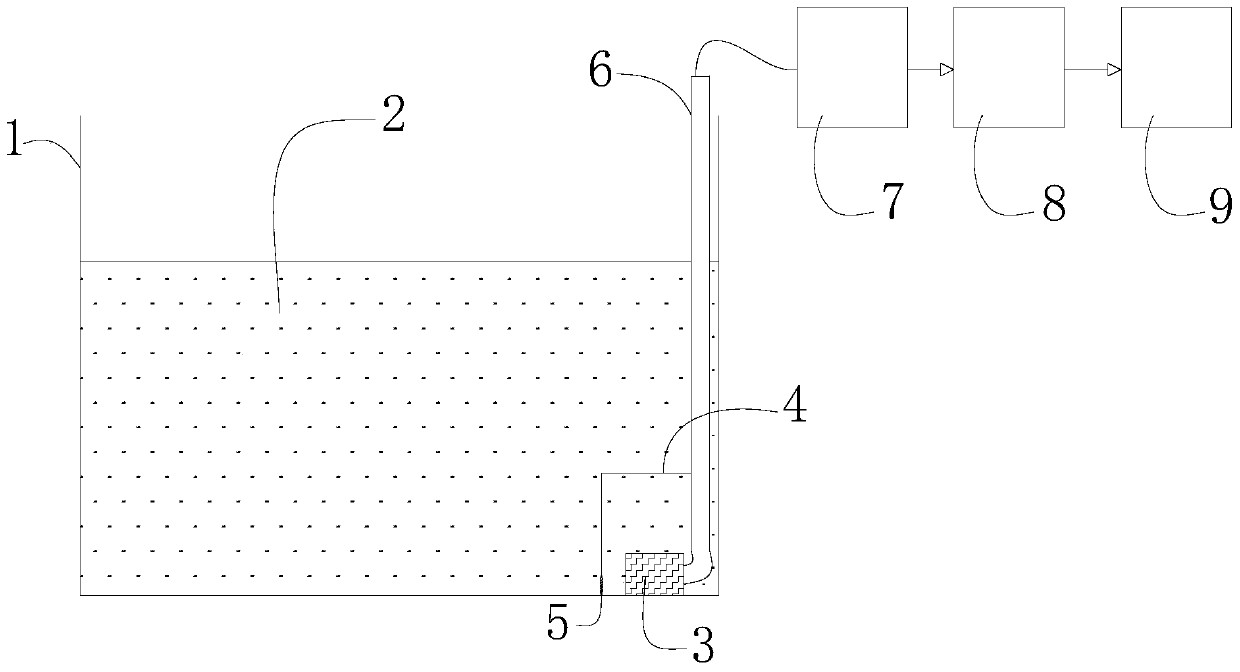

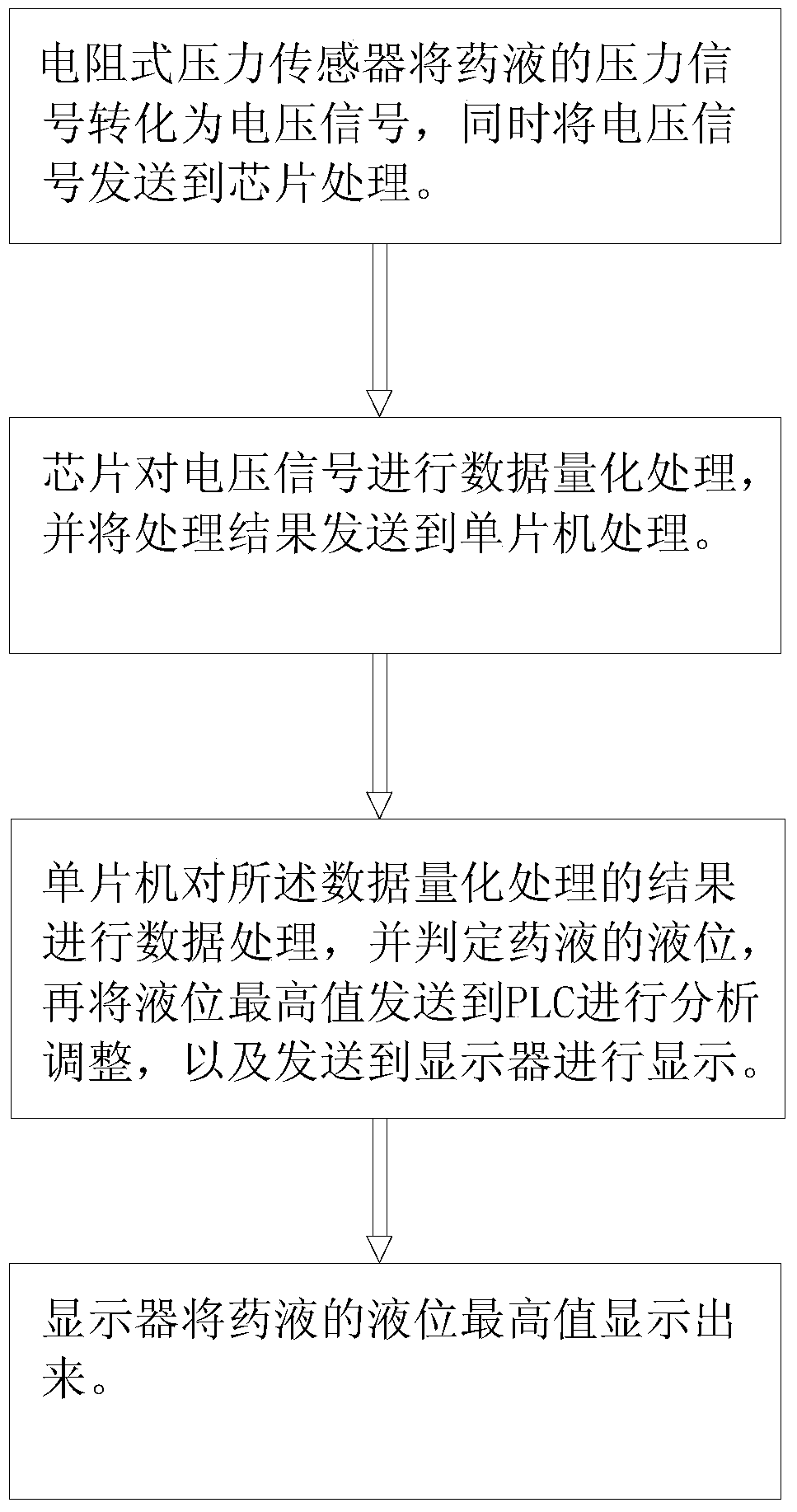

[0027] Such as figure 1 Shown is a schematic diagram of the composition framework of a wet etching device of the present invention. Such as figure 2 Shown is a schematic diagram of the workflow of a wet etching device of the present invention. from figure 1 As can be seen from the figure, a wet etching device of the present invention includes a chemical tank 1, a resistive pressure sensor 3, a chip 7, a single-chip microcomputer 8 and a display 9, wherein the chip 7 communicates with the The resistive pressure sensor 3 is connected, the chip 7 is connected to the single-chip microcomputer 8 by wires, the single-chip microcomputer 8 is connected to the display 9 by wires, and the resistive pressure sensor 3, the chip 7 and the single-chip microcomputer 8 are all connected to the power supply connect.

[0028] Below, each part of a kind of wet etching device of the present invention is introduced:

[0029] The chemical tank 1 of the present invention is used to contain a c...

Embodiment 2

[0038] This embodiment is substantially the same as Embodiment 1, except that the number of the resistive pressure sensors 3 in this embodiment is two. In order to obtain more accurate measurement results, in this embodiment, two resistive pressure sensors 3 are installed on the side of the bottom of the chemical tank 1, so that two sets of measurement data can be obtained, and if the difference between the two sets of data is small, it means that the measurement results are normal , and their average value can be taken as the measured value. If there is a big difference between the two sets of data, it means that at least one of the resistive pressure sensors 3 has a problem, and the resistive pressure sensor 3 must be inspected and repaired.

[0039] Another reason for installing two resistive pressure sensors 3 in the chemical tank 1 in this embodiment is that once one of the resistive pressure sensors 3 is broken, the other can continue to work normally, ensuring the conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com