Semiconductor packaging structure and packaging method

A technology of packaging structure and packaging method, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components and other directions, can solve the problems of unequal volume, open-circuit pillow effect failure, vertical chip fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

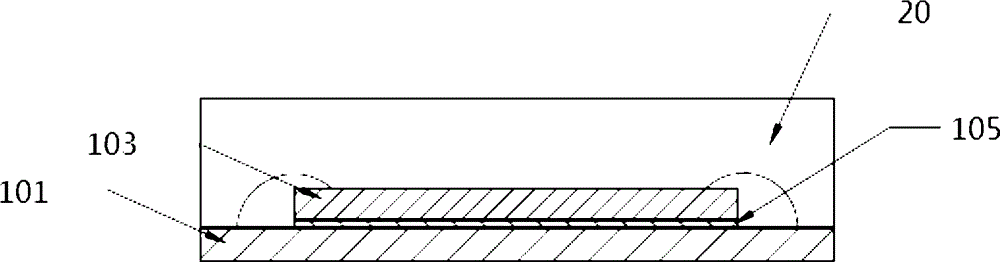

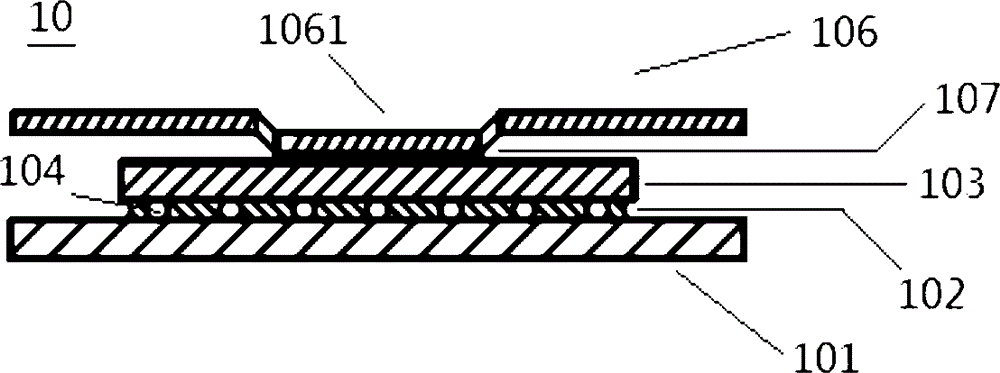

[0044] figure 2 and image 3 A schematic structural diagram of a semiconductor package structure according to two implementations of the present invention is shown. Such as figure 2 and image 3 As shown, the semiconductor package structure 10 may include: a substrate 101, a chip 103 located on the substrate 101 and electrically connected to the substrate 101, and a packaging layer for packaging the chip 103 (although in figure 2 and image 3 It is not shown in , but it can be understood that the encapsulation layer can be, for example, the encapsulation layer 20 shown in FIG. 1).

[0045] figure 2 An example of realizing the electrical connection bet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap