High-strength hedgerow cutter

A high-strength, hedgerow technology, used in hedge trimming equipment, cutting equipment, agricultural machinery and implements, etc., can solve problems such as blade deformation, blade collision, etc., to achieve strong pruning strength, avoid mutual collision, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

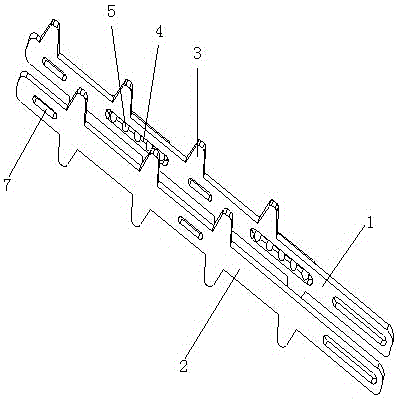

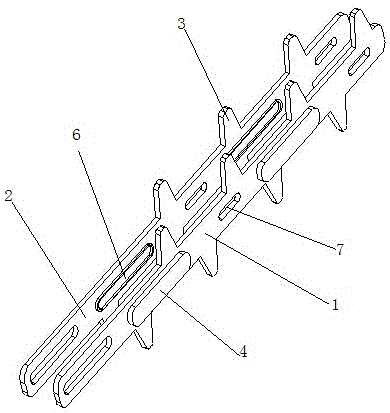

[0012] As shown in the figure, the present invention provides a high-strength hedge knife, including a first blade 1 and a second blade 2, both of which have a blade 3 on the first blade 1 and the second blade 2, and the first blade 1 and the second blade 2 The blades 3 on the first blade 1 and the blades 3 on the second blade 2 are arranged alternately;

[0013] There are multiple sets of supporting units on the face of the first blade 1 facing the second blade 2, the supporting units include a ball bearing box 4 and a plurality of ball bearings 5 limited in the ball housing box 4, and the ball bearings are accommodated One side of the box 4 is open, the inner cavity of the ball storage box 4 is connected with the surface of the first blade 1 facing the second blade 2, and each ball 5 in the ball storage box 4 is partially exposed to the Bead holding box 4 exterior.

[0014] When in use, the part of the ball 5 exposed to the ball housing box 4 has a certain gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com