Hot-pot pan with electric lifting structure

A lifting structure and hot pot technology, applied to cooking utensils with water bath devices, plug-ins, etc., can solve the problems of easy boiled food, sticky pot, and direct contact of food with the bottom of the pot, so as to avoid the production of harmful substances and the loss of nutrients , to avoid the effect of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

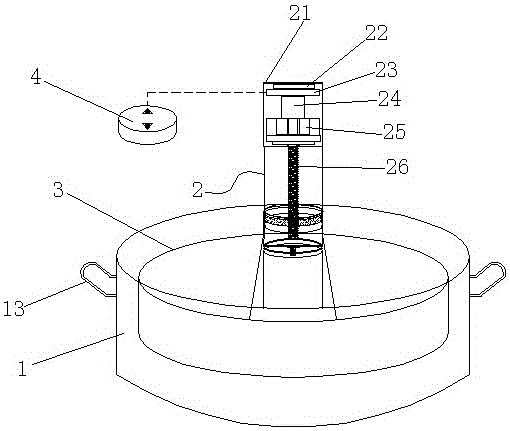

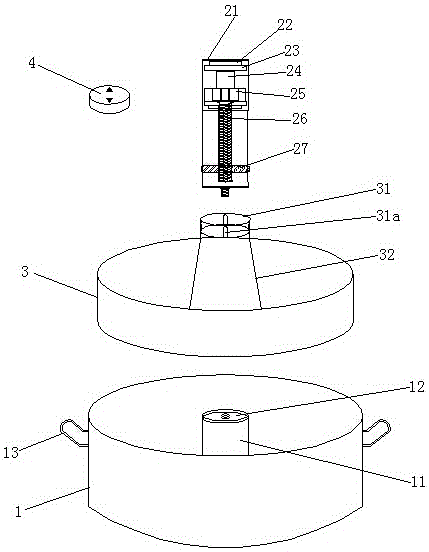

[0032] Such as Figure 1 to Figure 5 The example shown,

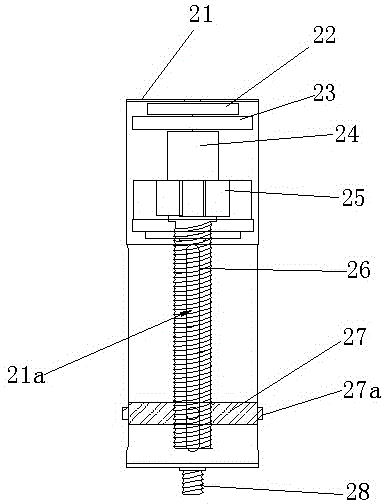

[0033] Description of icon numbers: outer pot body 1, mounting column 11, connecting nut 12, handle 13, lifting assembly 2, shell 21, guide rail 21a, battery 22, circuit board 23, motor 24, reducer 25, screw rod 26, lifting nut 27. Fixed pin 27a, connecting screw 28, inner pot body 3, first soup leakage hole 3a, second soup leakage hole 3b, guide post sleeve 31, connection hole 31a, connection sleeve 32, rib 33, controller 4.

[0034] Such as Figure 1 to Figure 5 as shown,

[0035] A hot pot pot with an electric lifting structure in the present invention includes an outer pot body 1, and a lifting assembly 2 is vertically arranged in the center of the outer pot body 1, and the lifting assembly 2 includes a casing 21, which is arranged in the casing 21 The battery 22, the circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com