A New Separation Micro Grinder

A grinder and separate technology, which is applied in the field of new separate micro grinder, can solve the problems that the grinder cannot be sterilized by high temperature and high pressure steam, the grinder is expensive, and cannot be fully ground, so as to improve the grinding efficiency and simple structure , The effect of material selection safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

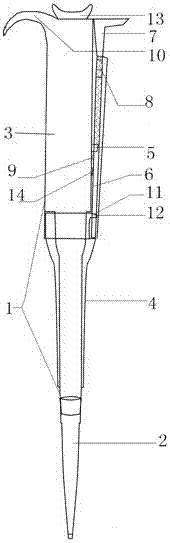

[0015] Embodiment of the present invention: a new type of separate micro grinder, as shown in the accompanying drawings, including a grinder body 1 and a grinder head 2, the length of the whole grinder after assembly is 26 cm, and the grinder body 1 includes a grinding pestle 3 and the remover 4 set in the middle of the grinding pestle 3, the remover 4 moves up and down along the grinding pestle 3, and the ring-shaped clamping table 5 is fixed in the middle of the grinding pestle 3, and the connecting rod 6 is vertically inserted into the ring-shaped clamping table 5 And the bottom of the connecting rod 6 is connected with the upper edge of the remover 4, the connecting mode of the connecting rod 6 and the remover 4 adopts that a connecting groove 11 is set at the lower end of the connecting rod 6, and a boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com