Pipe bender

A pipe bender and pipe bending technology, which is applied in the field of pipe benders, can solve problems such as difficulty in applying force by the operator and affect the efficiency and quality of pipe bending processing, and achieve the effects of convenient and quick angle adjustment, simple structure, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

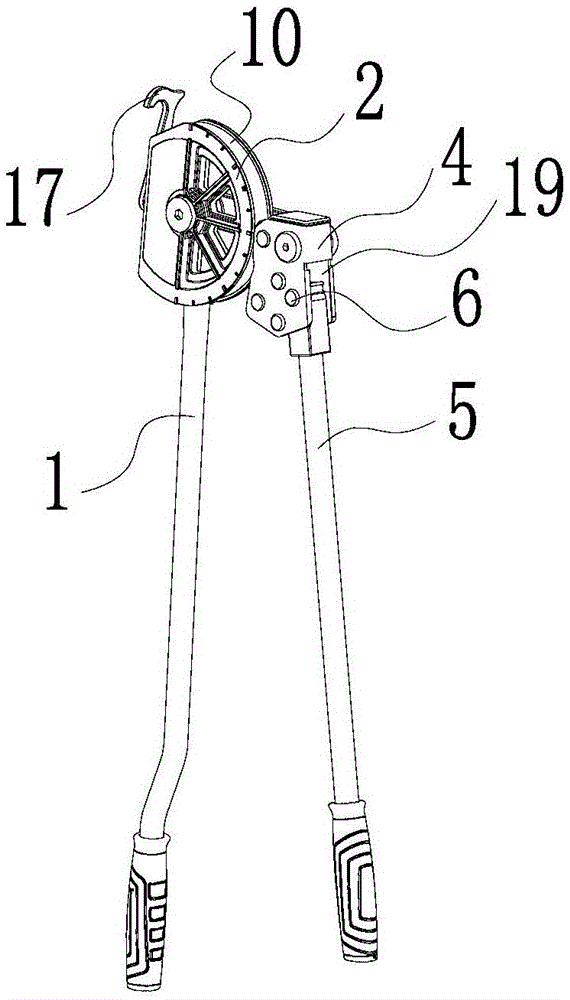

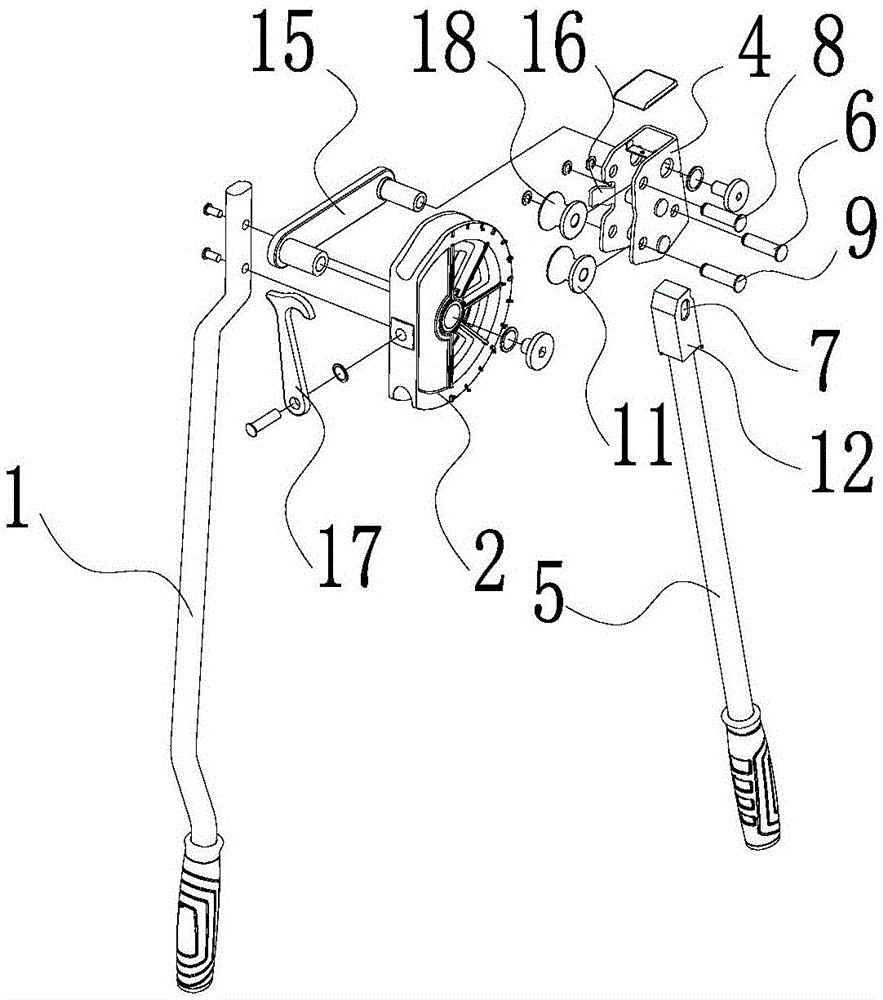

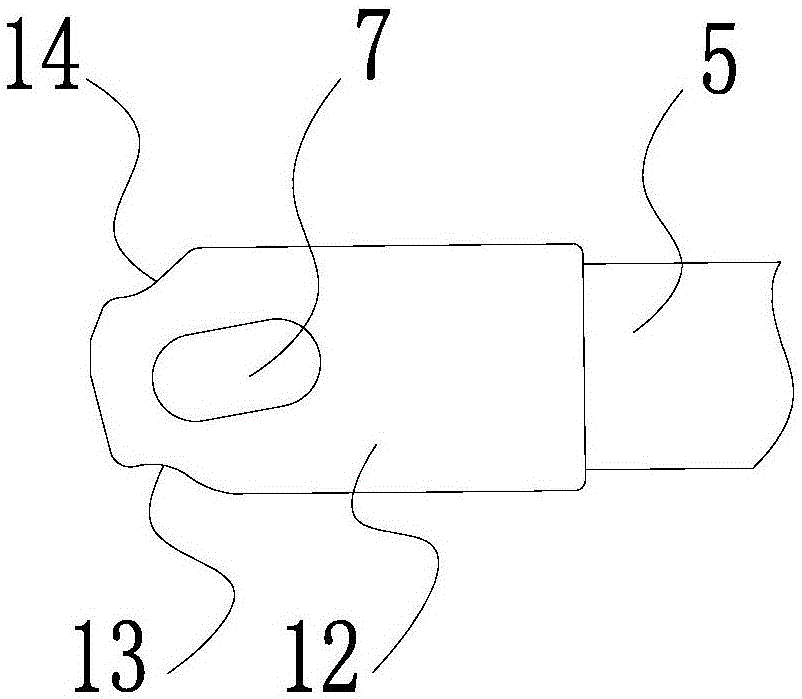

[0023] Such as figure 1 and figure 2 As shown, a pipe bender of the present invention includes a fixed handle 1 and a semicircular pipe bender 2 fixed at one end of the fixed handle 1 by screws, and a U-shaped biaxial connecting rod 15 is passed on the bender 2 Rotatingly connected with the pressure tube head 4 that can hold the copper tube 3 and rotate along its outer ring surface, one end of the biaxial connecting rod 15 is connected in the middle hole of the bending tube disc 2, and the other end is rotated on the pressure tube head 4 , the crimping head 4 is a U-shaped structure that is rollingly connected to the outer ring surface of the elbow disc 2, and the opening faces the center of the elbow disc 2, and a rotating shaft is fixed laterally between the two side walls of the bottom of the U-shaped crimping head 4 6. The inner end of the pressure tube handle 5 is rotatably connected to the corresponding rotating shaft 6 between the openings through the long arc hole 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com