Self-suction injection pump movable sheet type check-valve

A jet pump and flap type technology, which is applied in the field of self-priming jet pump flap type check valve, achieves the effects of labor-saving processing, low cost and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

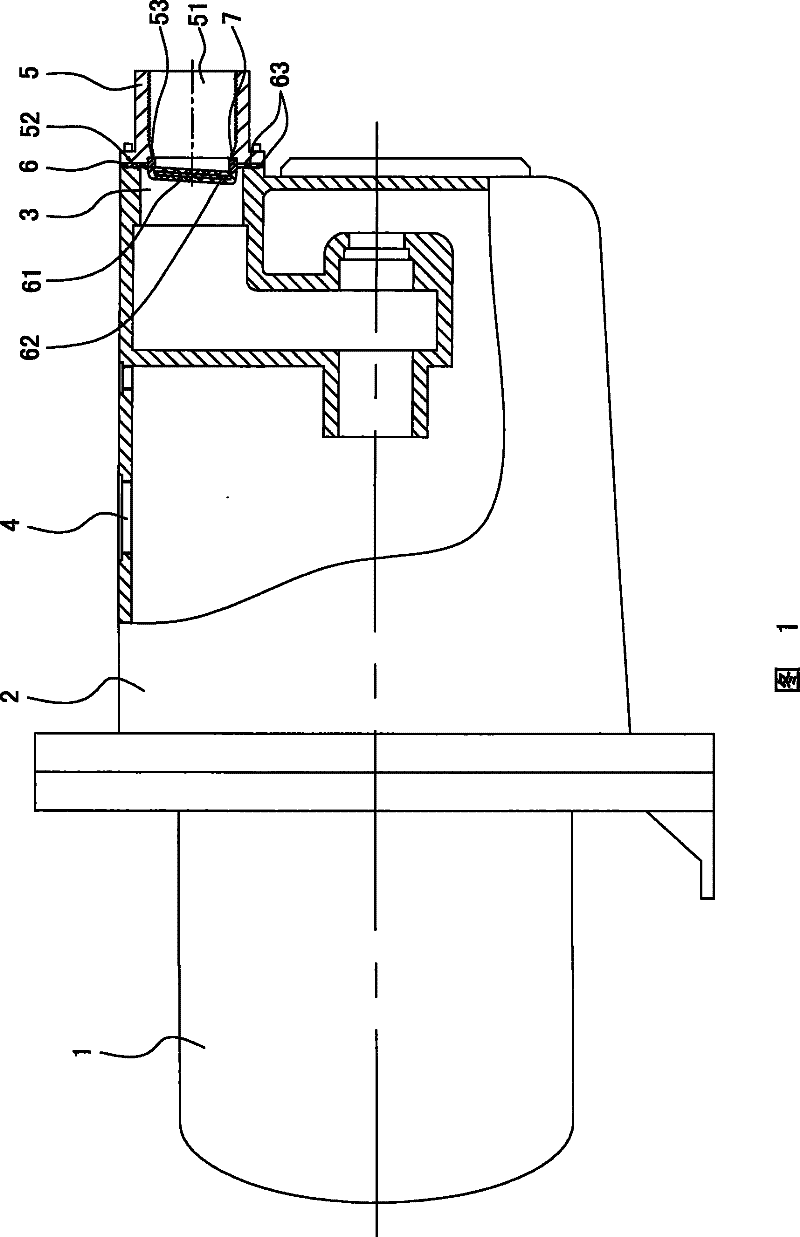

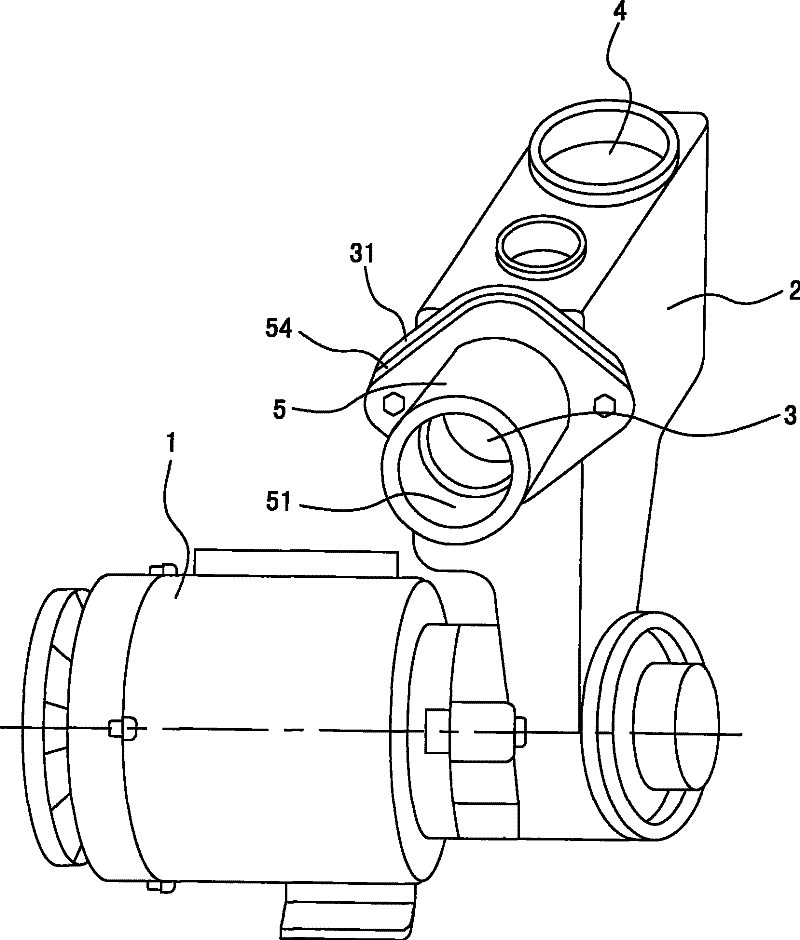

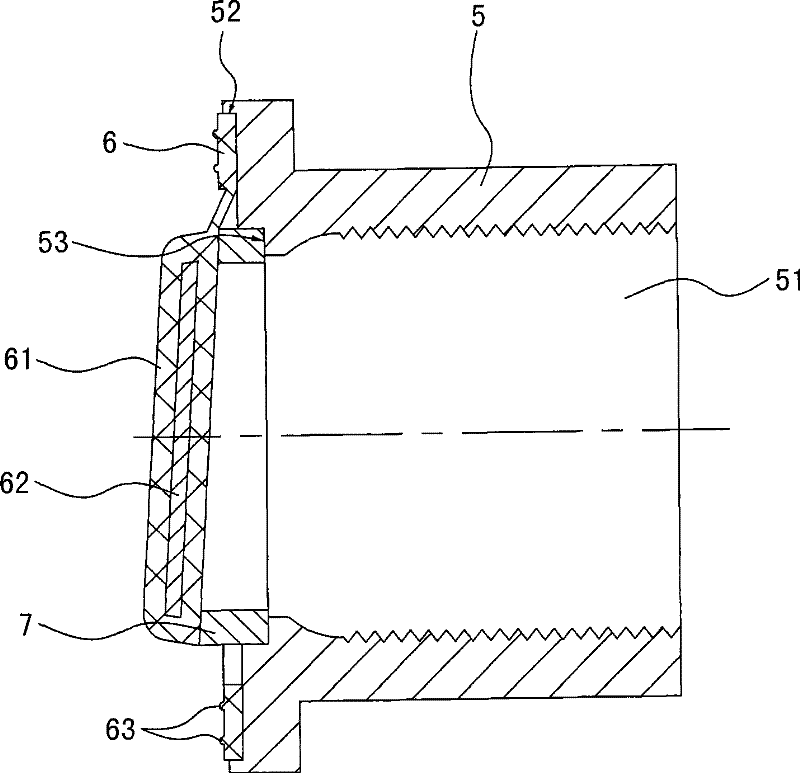

[0017] The present invention relates to self-priming jet pump flap type check valve, such as figure 1 — Figure 6 As shown, there is a motor 1, the motor is connected to the pump body 2, and the pump body has a water inlet 3 and a water outlet 4. Its main technical feature is that the water inlet 3 is connected to the valve seat 5, and the valve seat 5 has a valve hole 51 connected to the valve hole. Inlet pipe, valve seat is shaped on circular dimple 52, and rubber sheet seat 6 is installed in the dimple 52, and rubber sheet seat 6 connects rubber valve disc 61, and rubber valve disc 61 matches with the valve hole 51 of valve seat. Compared with the prior art, this technical solution has the following advantages: 1. The valve seat is connected to the water inlet of the pump body, and there is a shallow dimple in the valve seat to install the rubber sheet seat. First, the positioning of the rubber sheet seat is conducive to assembly , the second is beneficial to the determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com