Welding process for oil pipe of main transformer of electric locomotive

A technology for main transformers and electric locomotives, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor seal durability and leakage of transformer oil pipe welds, and achieve good weld seal durability and good promotion function, ensure functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

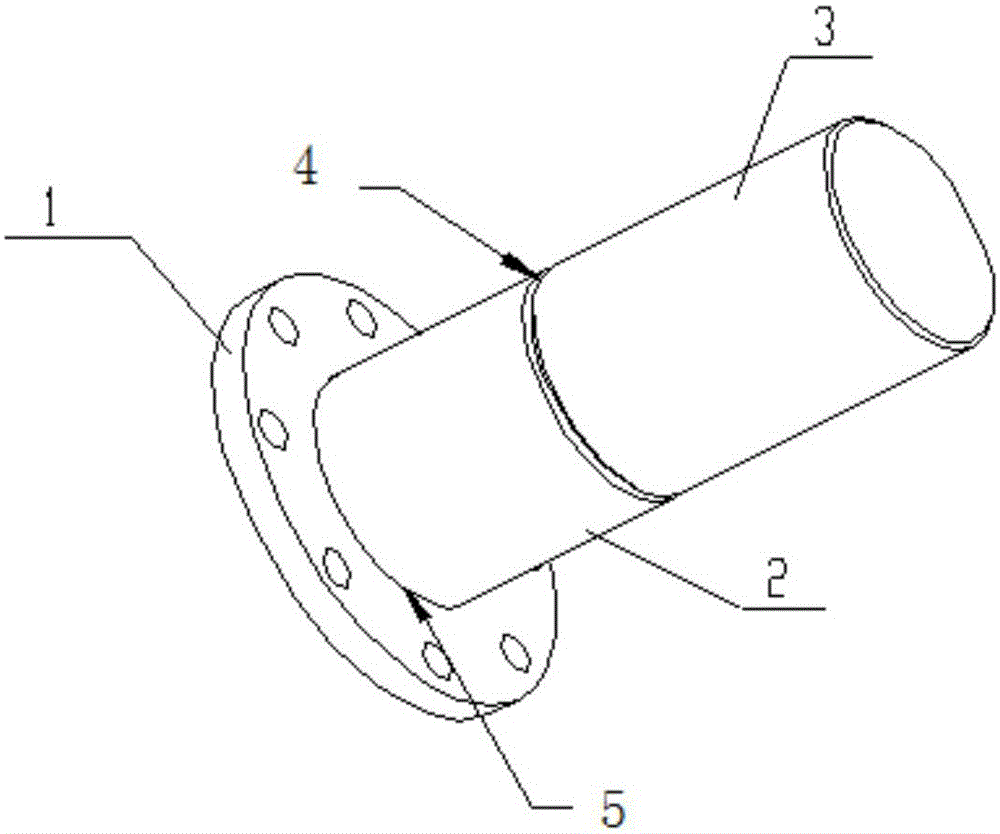

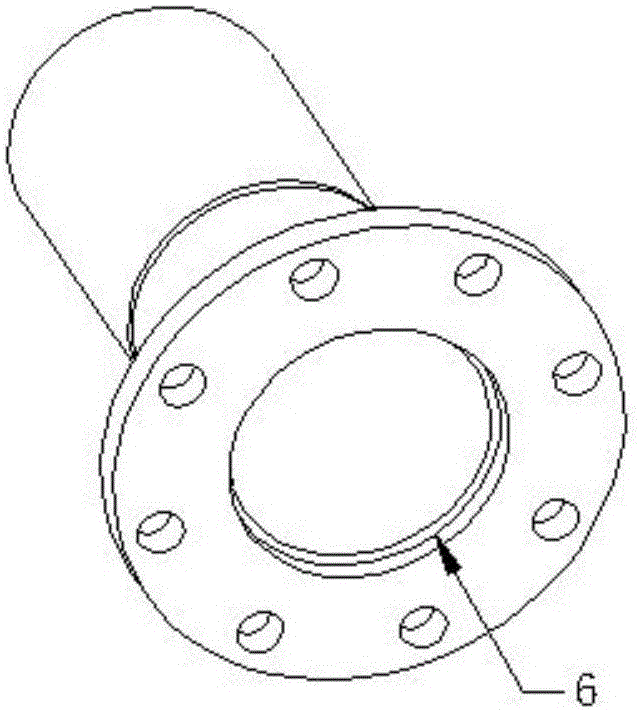

[0026] now attached figure 1 to attach figure 2 , to further explain the present invention: the present invention mainly uses a new welding process for the welds between pipe fittings, the main transformer cooling oil pipeline is mainly composed of flanges and pipelines, and the pipelines are connected by welding, and the welding includes pipelines Butt joint welding with pipelines, joint welding between pipelines and flanges, the structure and weld position of pipelines refer to figure 1 , figure 2 , the specific content of the process is as follows:

[0027] It is mainly explained from the aspects of welding method selection, setting specifications of welding parameters, weld seam inspection and treatment after welding, hydraulic test, etc. The specific process flow is: pre-weld preparation—position welding—pipe fitting welding—weld seam treatment— hydrostatictest.

[0028] The first step, preparation before welding;

[0029] 1) The carbon steel chemical electrode use...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap