Formwork and bracket combining structure of vase pier of viaduct and application method

A technology of combined structure and vase piers, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of affecting the appearance, damaging the concrete, and low bearing capacity, and achieves high economic and social benefits, standardized construction, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

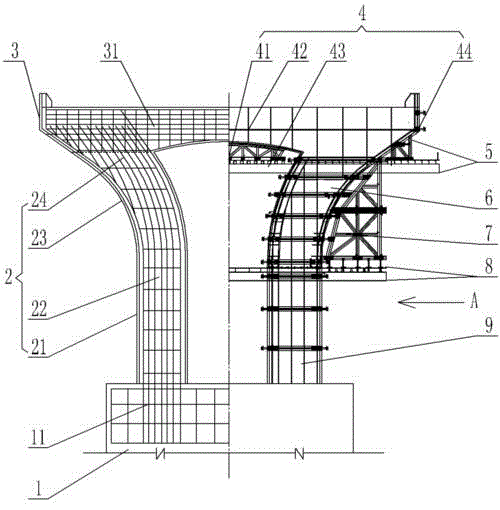

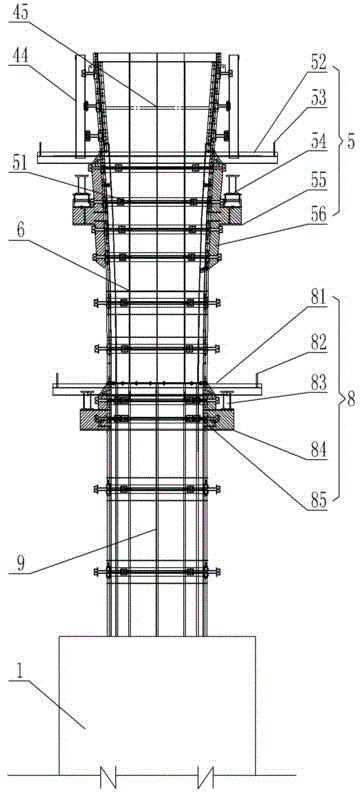

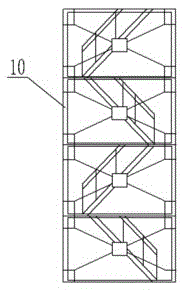

[0055] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

[0056] Such as Figure 1~Figure 5 As shown, 1. cap, 11. cap reinforcement, 2. pier column, 21. straight section pier column, 22. straight section steel skeleton, 23. curved section pier column, 24. curved section steel skeleton, 3. cover Beam, 31. Cover beam steel skeleton, 4. Cover beam formwork, 41. Cover beam bottom formwork support, 42. Cover beam elevation formwork, 43. Cover beam bottom formwork, 44. Cover beam side formwork support, 45. Cover beam Side formwork, 5. Upper bracket, 51. Upper bracket pull rod, 52. Upper bracket platform, 53. Upper bracket railing, 54. Upper bracket longitudinal beam, 55. Upper bracket beam, 56. Upper bracket bottom bracket, 6. Curved section Formwork support, 7. Curve section formwork, 8. Lower support, 81. Lower support platform, 82. Lower support railing, 83. Lower support longitudinal beam, 84. Lower support be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com