Cable well lid assembly

A technology for cable manhole covers and components, applied in construction, artificial island, infrastructure engineering, etc., can solve problems such as hidden dangers, people are easily injured, and pedestrians or vehicles are not easy to travel, so as to improve the working environment, improve safety, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

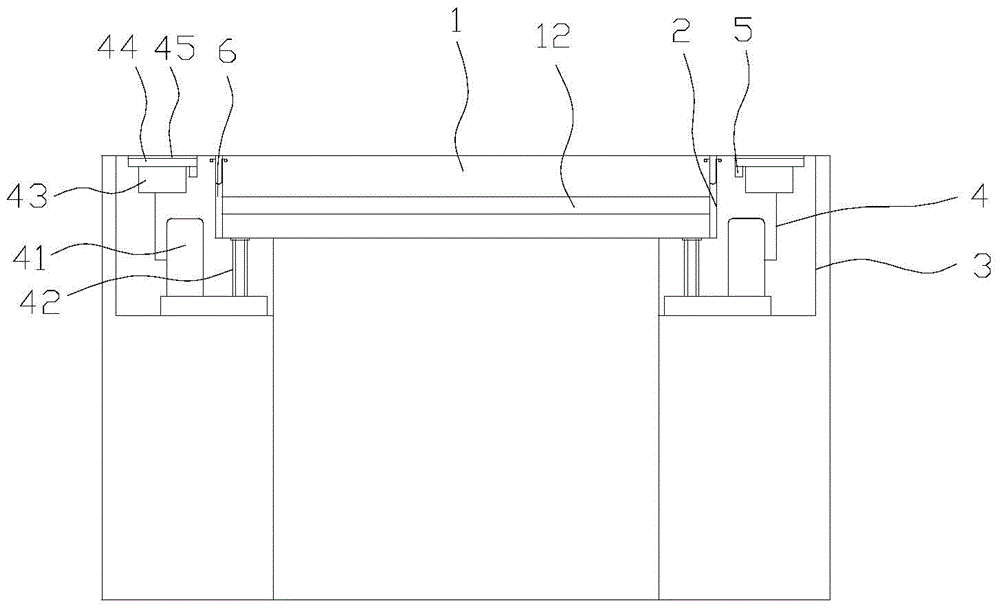

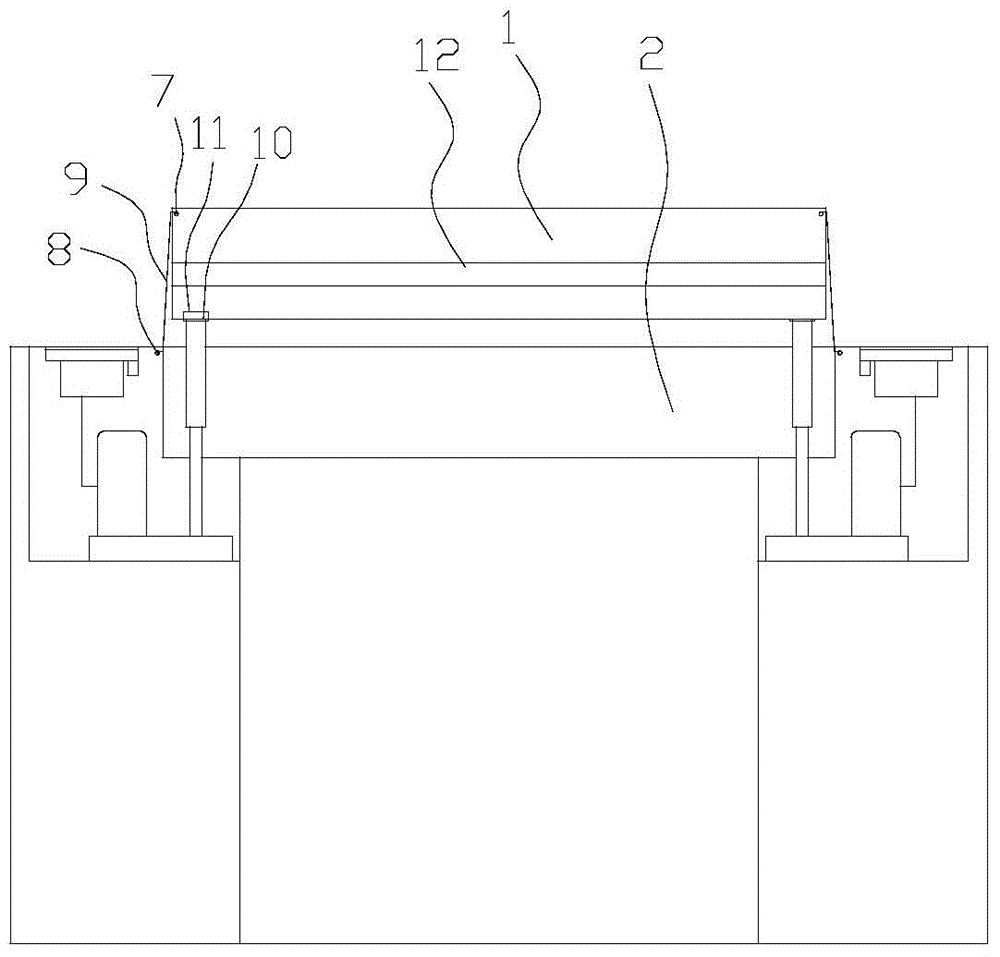

[0017] The present invention as Figure 1-2 As shown, it includes a cover body 1, and the cover body 1 is arranged on the wellhead 2 of the cable well; it also includes an opening device, and the opening device includes four sets of lifting mechanisms 4, and the two sides of the wellhead 2 are respectively equipped with accommodating Hole 3, four groups of lifting mechanisms are symmetrically arranged in the containing hole 3 (two containing holes on one side, and four groups of lifting mechanisms are respectively arranged in the four containing holes); during work, the lifting mechanism is set at On both sides of the wellhead, the distance between the push rod and the cover body is shortened, the reliability and stability of the push rod work are improved; at the same time, the service life of the lifting mechanism is improved, and it is avoided to be installed at the bottom of the well.

[0018] The lifting mechanism includes an electric push rod assembly, a rain sensor 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com