Fiber welding method and device

An optical fiber fusion splicing and optical fiber technology, applied in the field of optical fiber, can solve the problems of fiber core dislocation, optical fiber transmission loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

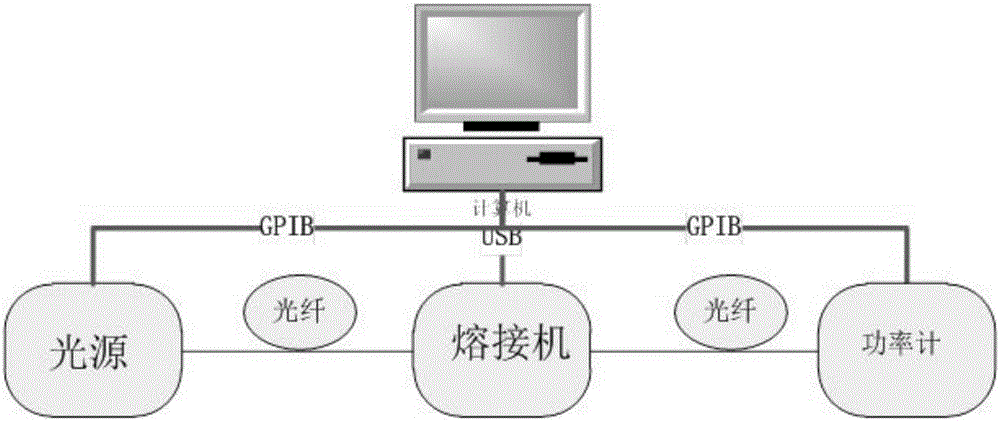

[0074] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0075] One of the core concepts of the embodiments of the present application is to determine the position of the maximum power value by scanning the end face of the optical fiber, then adjust the optical fiber to the position of the maximum power value, and perform fusion splicing on the optical fiber after the position adjustment is completed.

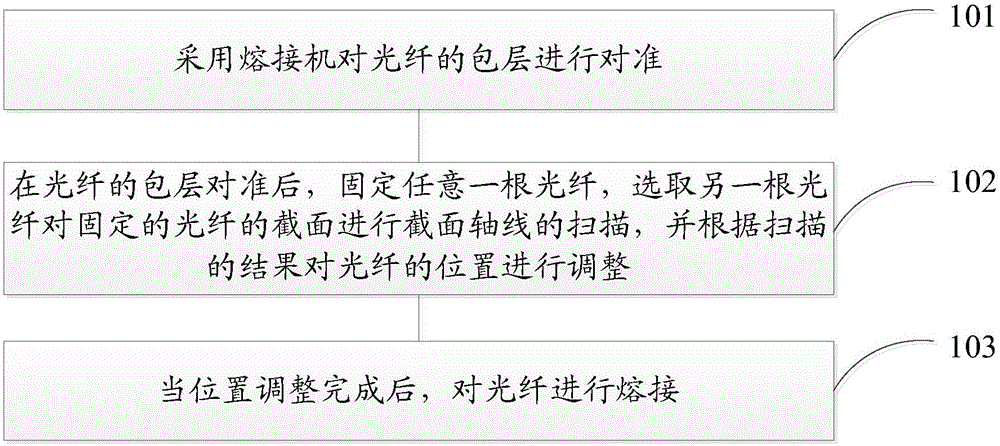

[0076] refer to figure 1 , which shows a flow chart of the steps of an embodiment of an optical fiber fusion splicing method of the present application, which may specifically include the following steps:

[0077] Step 101, using a fusion splicer to align the cladding of the optical fiber;

[0078] Step 102, after the cladding of the optical fiber is aligned, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com