Production method of saloon car transmission combination gear ring

A production method and technology of combining teeth, applied to components with teeth, wheels, vehicle parts, etc., can solve the problems of low production efficiency, reduced comprehensive mechanical performance, waste of metal materials and other problems of car transmissions combined with gear rings, and achieve easy large-scale The effects of mass production, improved bearing capacity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

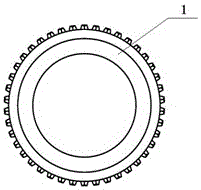

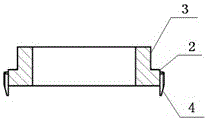

[0021] Example: see figure 1 , figure 2 and image 3 As shown, a combination gear ring of a car transmission includes a ring body 1 and outer teeth arranged on the outside of the ring body 1. The outer wall of the ring body 1 is a two-stage outer circle structure----a large outer circular wall 2 and a small outer circular wall. The circular wall 3, the large outer circular wall 2 is provided with a conical external tooth 4 with an inverted conical surface structure, the tooth width of the conical external tooth 4 is greater than the thickness of the large external circular wall 2, and the ring The body 1 and the tapered external teeth 4 are an integral structure, and the combined tooth ring has a maximum diameter of ≤100mm, a height of ≤30mm, and a weight of ≤600g.

[0022] see Figure 4 As shown, the production method of the car transmission combined with the ring gear comprises the following process steps:

[0023] Cutting material: 20CrMoH material, use a circular sawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com