Mechanical clamp

A fixture and mechanical technology, which is applied in the field of mechanical auxiliary tooling, can solve problems such as danger and safety accidents of locking parts, and achieve the effect of increasing the safety factor, firm installation method, and not easy to cause safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

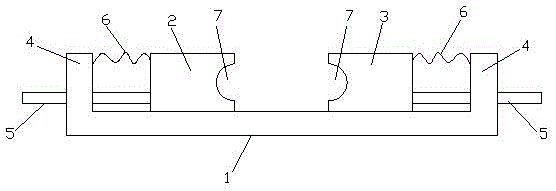

[0012] Such as figure 1 As shown, a kind of mechanical fixture comprises a base 1, a left clamp body 2 and a right clamp body 3; the left and right clamp bodies are respectively placed on the left and right sides of the base 1; and the left and right ends of the base 1 Both are provided with side plates 4; and a push rod 5 is installed on the two side plates 4, and the push rod 5 on the left side plate 4 is connected to the left clamp body 2; the push rod on the right side plate 4 5 is connected to the right clamp body 3.

[0013] Wherein, springs 6 are also connected to the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com