Clamping mechanism for micro-arc oxidation on top of aluminum alloy piston

A technology of micro-arc oxidation and clamping mechanism, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc. It can solve the problems of easily damaged aluminum alloy pistons, falling in the electrolyte, and easy breakage, etc., to achieve fixed The method is stable and firm, avoids electrical conductivity, and improves operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

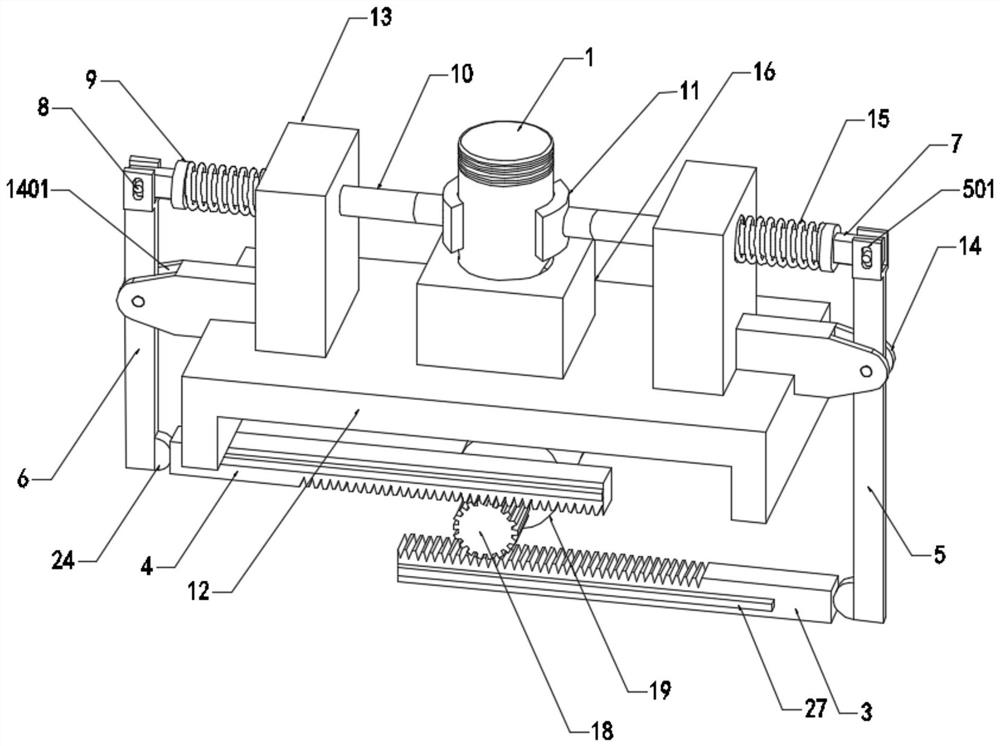

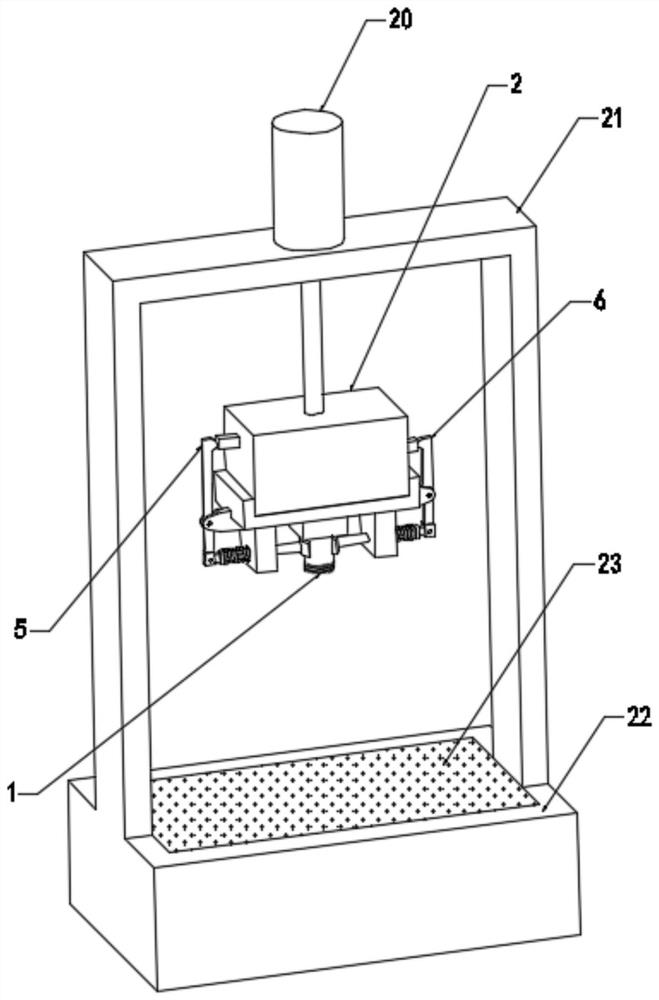

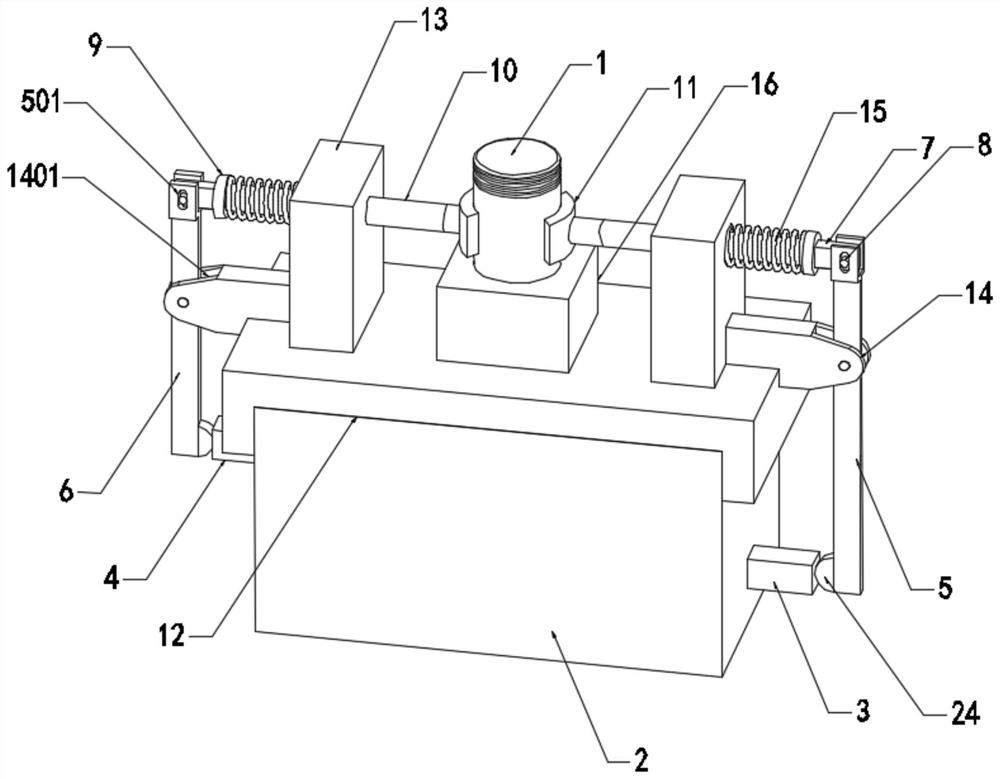

[0046] see Figure 1-10, the present invention provides a technical solution: a clamping mechanism based on micro-arc oxidation on the top of an aluminum alloy piston, including a mounting base 2, a fixing plate 12 is fixedly installed on the top of the mounting base 2, and a fixing plate 12 is fixedly installed on the top of the fixing plate 12 The base 16 is provided with a placement groove 1601 in the base 16, and the conductive rod 17 is fixedly installed in the base 16. Two fixed seats 13 are fixedly installed on the top of the fixed plate 12, and the second mobile slot 1301 is provided in the fixed seat 13. The fixed seat 13 A clamp bar 10 that moves in the second moving groove 1301 is provided inside. A clamp hand 11 is installed on one end of the clamp bar 10. The inner surface wall of the clamp hand 11 is bonded with a rubber layer 26. The other end of the clamp bar 10 is fixedly installed in a limited position. Block 9, the limit block 9 and one end of the second mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com