Wall grinding device for building construction

A technology for building construction and walls, applied in the fields of grinding and polishing, which can solve the problems of wall grinding intensity changes and uneven grinding, and achieve the effect of improving the stability of the fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

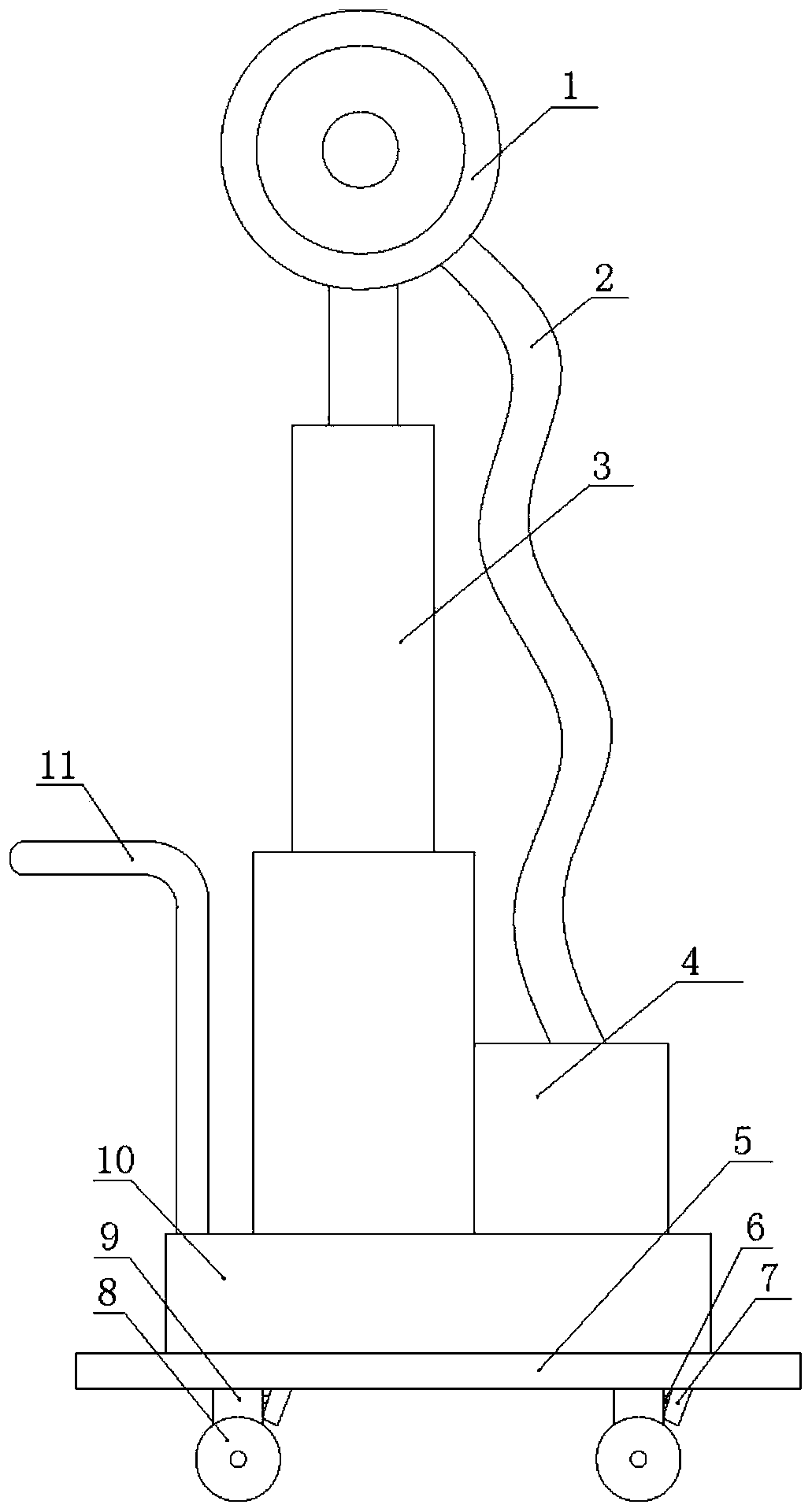

[0026] Such as figure 1 As shown, the wall grinding device for building construction includes a base 10 on which a telescopic rod 3 is vertically installed, and the telescopic rod 3 adopts an electric telescopic rod in the prior art. The top of telescopic rod 3 rotates and is equipped with grinding disc, and grinding disc is connected with motor. The grinding disc outer cover is provided with a dustproof cover 1, a dust collector 4 is installed on the base 10, and a conduit 2 is communicated between the dust collector 4 and the dustproof cover 1, and the conduit 2 adopts a flexible pipe in the prior art.

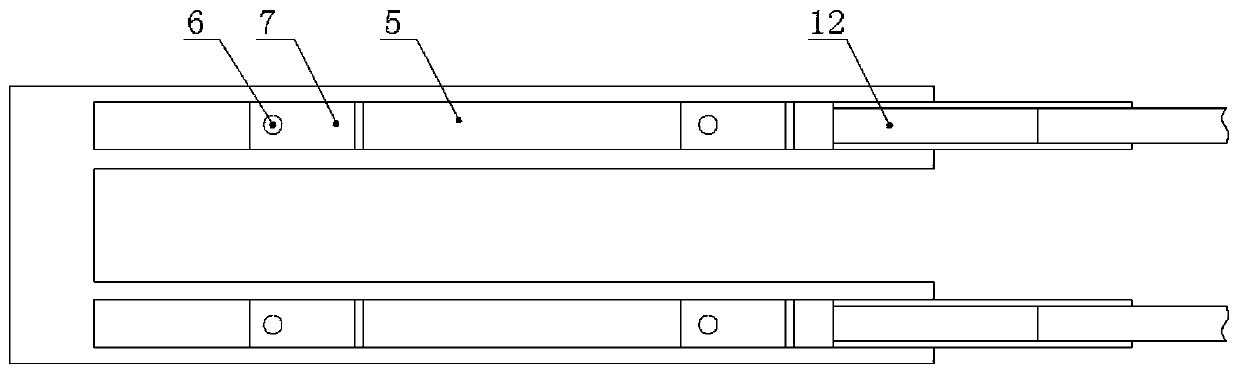

[0027] The bottom of the base 10 is vertically welded with a support column 9, and the bottom of the support column 9 is rotatably connected with a pulley 8, and a push handle 11 is also installed on the base 10 to promote the whole device to move. A guide rail is horizontally installed below the base 10, combined with figure 2 It can be seen that the guide rail includes ...

Embodiment 2

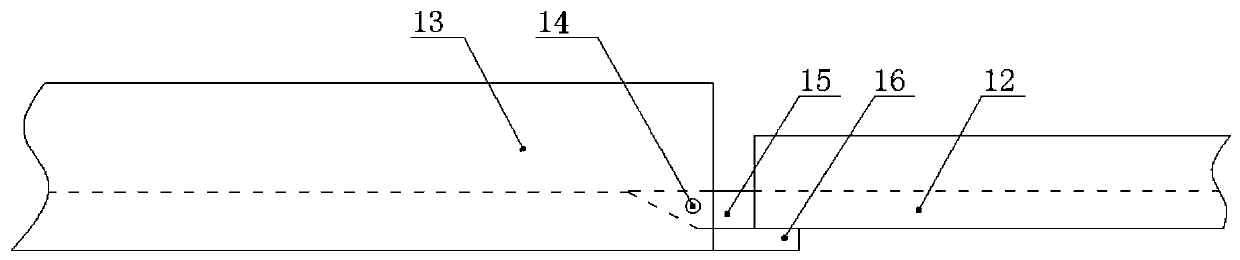

[0039] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that the movable section is hinged at the right end of the fixed section 5 , and the movable section can be folded outwards until it fits with the outer surface of the fixed section 5 . When not in use, the movable section is folded to be attached to the outer surface of the fixed section 5, which can reduce the volume of the present invention and is convenient for placement and carrying. During use, a complete guide rail can be formed for the pulley 8 to slide by turning over the movable section until the fixed section 5 is horizontally connected.

[0040] In order to increase the fixing stability of the movable section, in this embodiment, a first magnet is installed at the free end of the movable section, and a second magnet 17 for being attracted to the first magnet is installed on the fixed section 5 . The fixing stability of the movable section is improved by usi...

Embodiment 3

[0042] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that a calibration rod 19 is installed horizontally at both ends of one side of the base 10 , and the calibration rod 19 is perpendicular to the side of the base 10 . Calibration rod 19 adopts existing telescopic rod 3, and scale is engraved on the calibration rod 19. In practice, the calibration rod 19 can be pulled out to be against the wall, and the base 10 can be made parallel to the wall by making the lengths of the two calibration rods 19 the same, thereby realizing the calibration of the position of the base 10 . This embodiment is applicable to the situation where a certain distance is required between the base 10 and the wall, and the calibration cannot be achieved by attaching the base 10 to the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com