Exposed frame grooved hollow glass curtain wall mounting structure

A glass curtain wall and installation structure technology, applied to walls, building components, building structures, etc., can solve problems such as hidden dangers in use and maintenance, glass curtain wall falling off, etc., and achieve the effects of improving safety, preventing glass damage, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

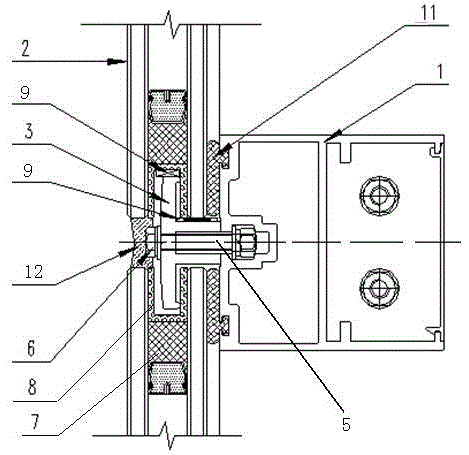

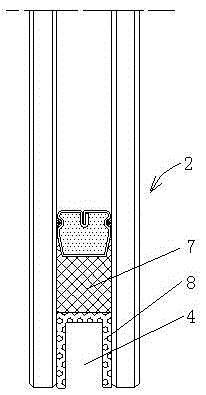

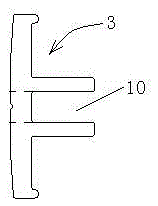

[0019] like figure 1 , 2 1. The installation structure of the hollow glass curtain wall with grooves in the exposed frame shown in 3, including a number of beams 1 fixed on the building wall, two pieces of hollow glass 2 arranged up and down are laid on the same beam 1, and the two pieces of hollow glass 2 are arranged There is a T-shaped pressing block 3. The T-shaped pressing block 3 includes the main rod and the left and right arms fixedly connected to the top of the main rod. In the U-shaped installation groove 4 of the U-shaped installation groove 4 and the inner sides of the left and right side arms are against the inner side wall of the U-shaped installation groove 4, the main rod of the T-shaped pressure block 3 extends inwardly against the beam 1, and the T-shaped pressure block 3 is provided with An axial through hole, the fastening bolt 5 preset in the beam 1 passes through the through hole and is connected with the nut 6 in cooperation. The T-shaped pressing bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com