Positioning tool for welding of high-pressure oil track support

A technology for positioning tooling and high-pressure oil, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of wrong spot welding position, easy misjudgment, etc., and achieve good welding quality and convenient maintenance and replacement , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

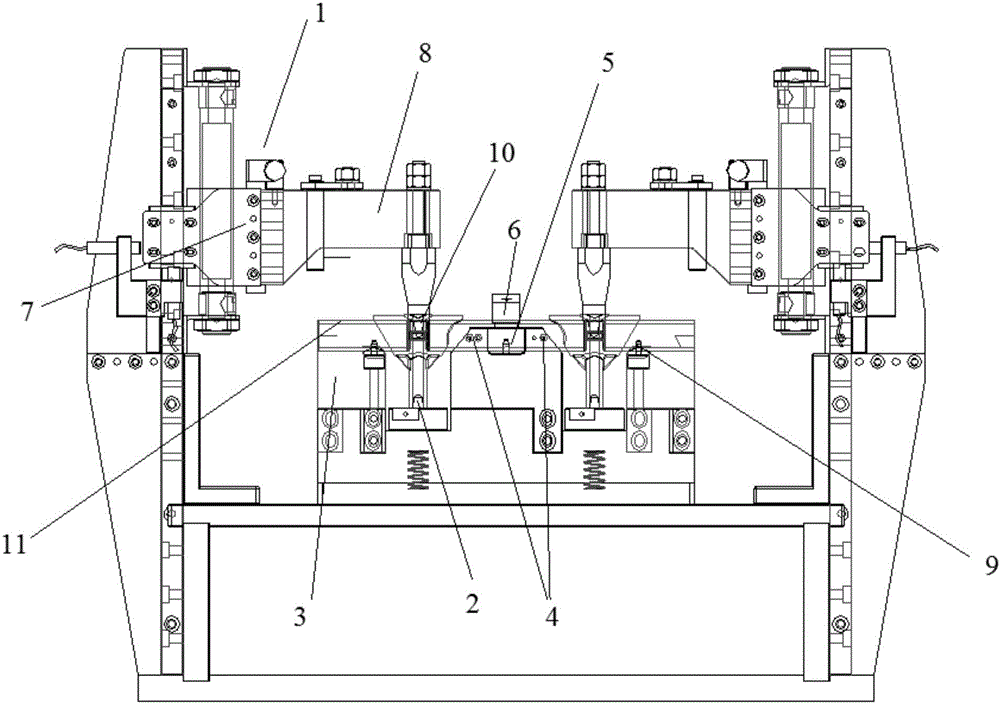

[0028] A positioning tool for welding of high-pressure oil rail brackets, its structure is as follows figure 1 As shown, the high-pressure oil rail includes a main pipe 11, and a column support arranged in the middle of the main pipe 11 and passing through the main pipe 11. Both ends of the main pipe 11 are provided with injector seat holes, and there are column through holes in the column support, positioning tooling It includes a workbench and a supervisor positioning platform 3 arranged on the workbench, and the workbench is a work turntable freely rotating around a central axis. The main pipe positioning platform 3 is provided with a main pipe positioning groove for placing the main pipe 11, and the main pipe positioning groove has seat hole positioning pins 9 for matching and inserting into the seat holes of the fuel injector and lower openings for matching and inserting into the through holes of the column column positioning pin a2.

[0029] The workbench is also equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com