A pay-off rack with automatic speed adjustment

A technology of automatic speed regulation and pay-off frame, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc. The effect of excessive force on the line body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the technical solution of the present invention will be described in detail through specific examples.

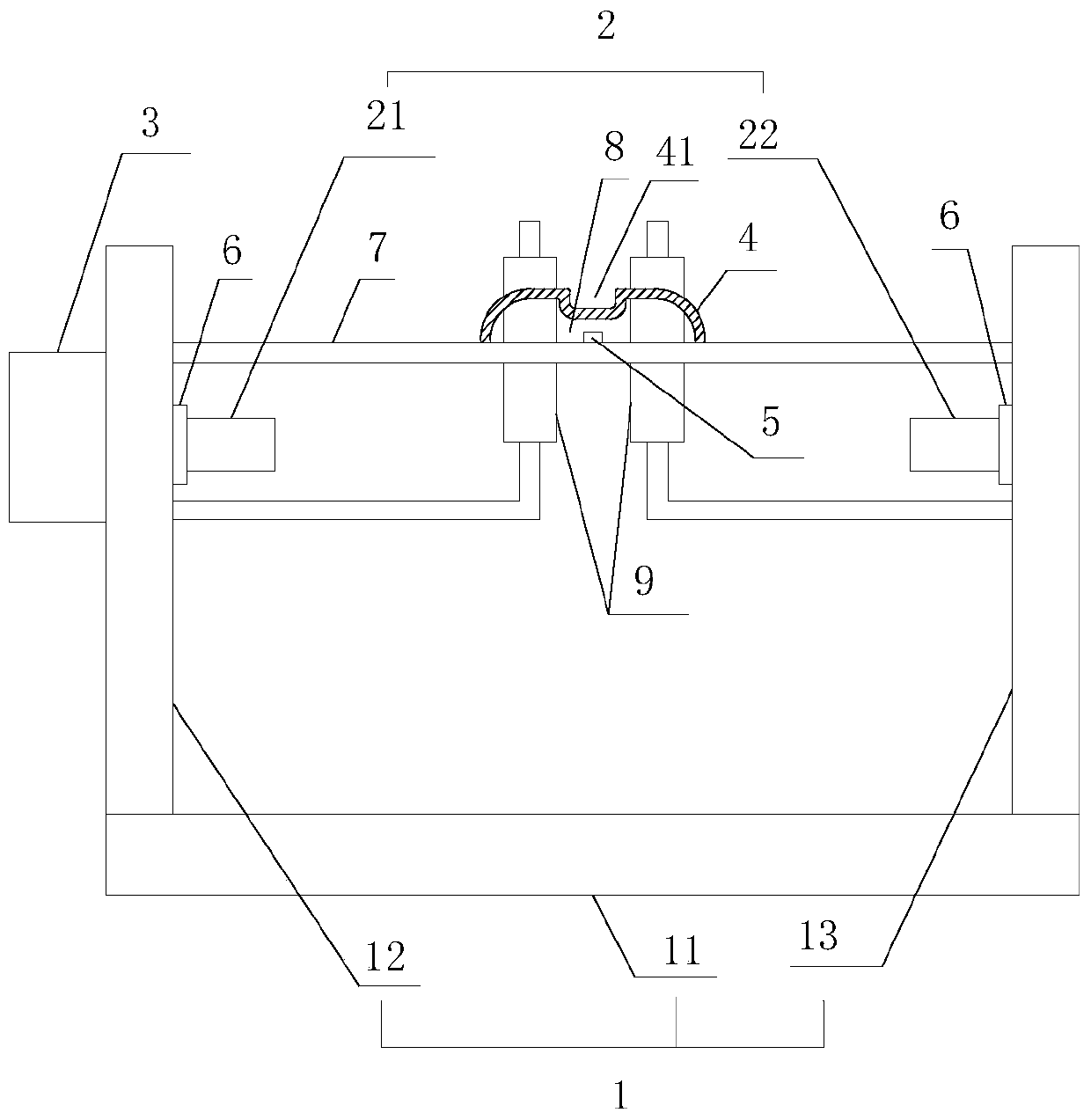

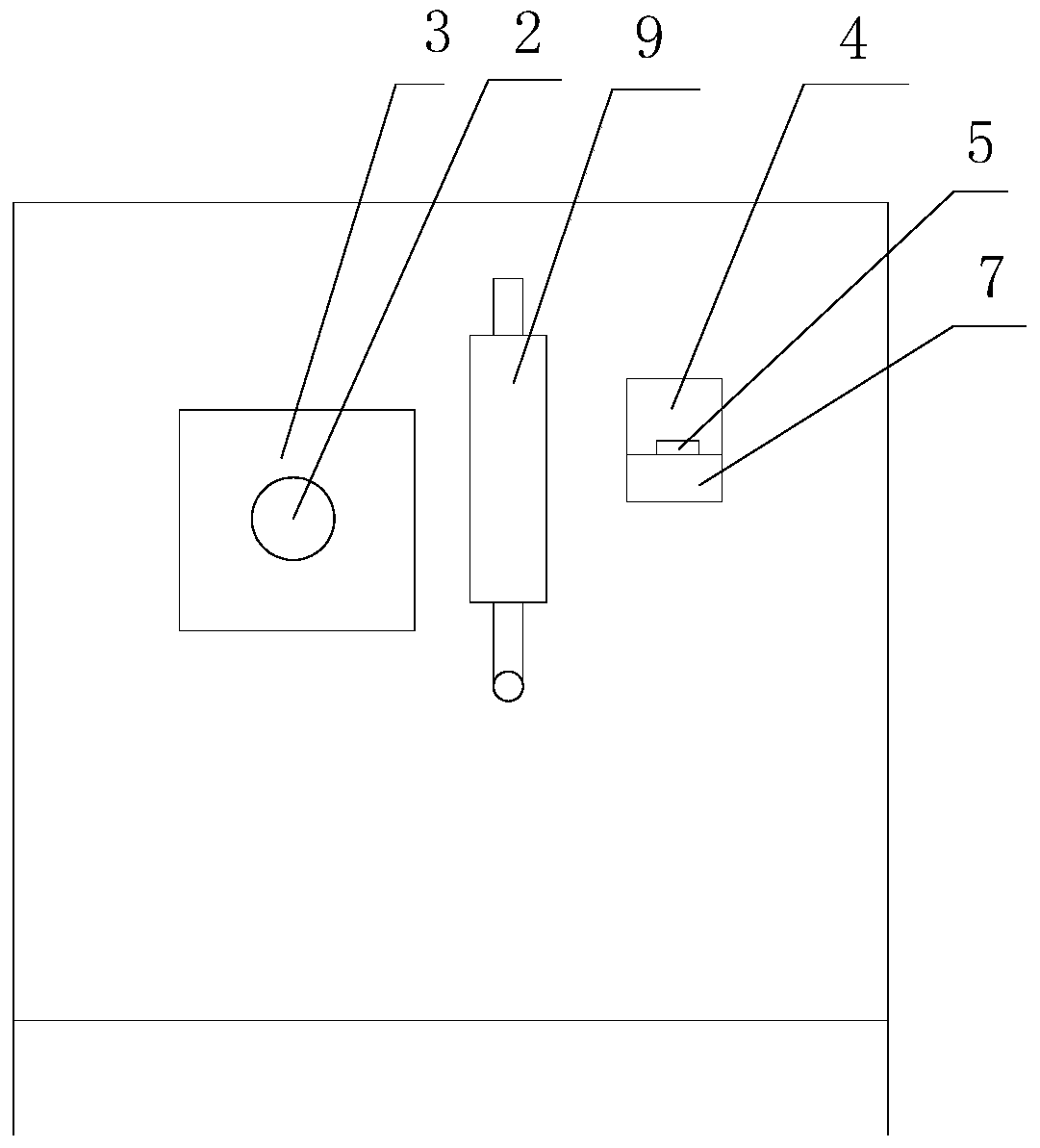

[0015] like Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a pay-off rack with automatic speed regulation proposed by the present invention; figure 2 It is a position relation diagram of each component in an automatic speed-regulating pay-off stand proposed by the present invention.

[0016] refer to Figure 1-2 , a pay-off rack with automatic speed regulation proposed by the embodiment of the present invention, comprising: a bracket 1, a pay-off shaft 2, a motor 3, an elastic diaphragm 4 and a sensor 5, wherein: the bracket 1 includes a base 11 and is relatively arranged on The left fixed mount 12 and the right fixed mount 13 of base 11 both sides; The output shaft is connected; the driven shaft 22 is fixed on the right holder 13 through the bearing 6, and in the working state, the driven shaft 22 is connected with the driving sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com