Drain valve based on safety improvement

A steam trap and safety technology, applied in steam traps, flange connections, passing components, etc., can solve the problems of low safety of steam traps, small fault tolerance space, pipeline deformation, etc., and achieve high disassembly and maintenance efficiency, High safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

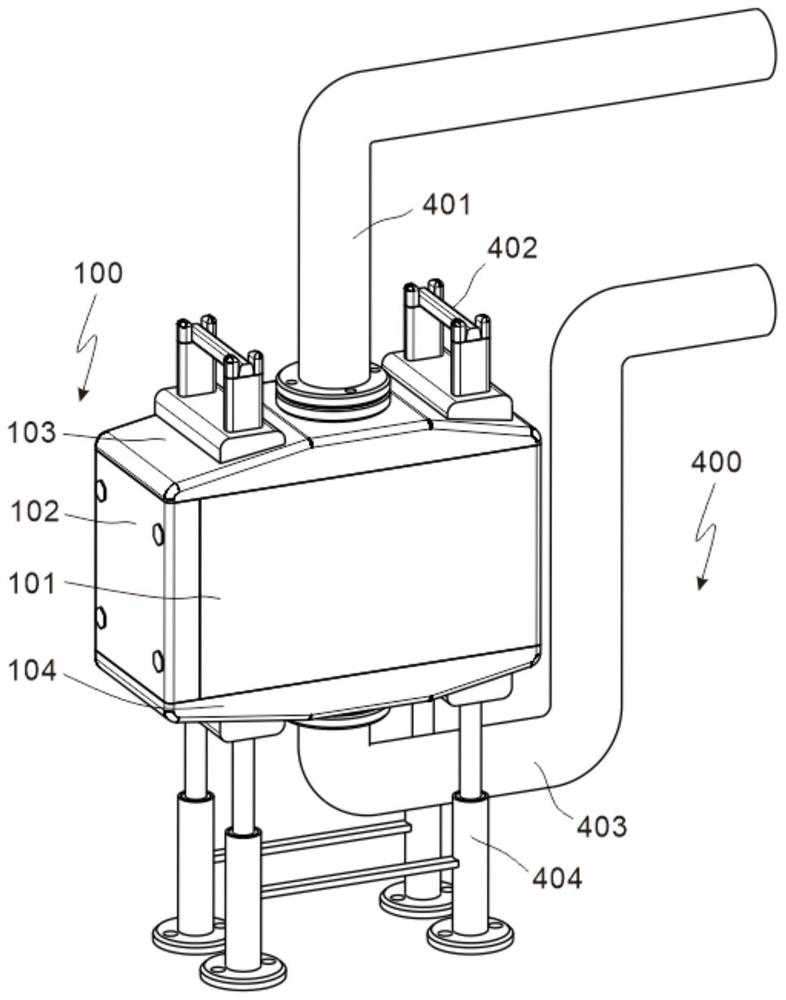

[0032] refer to figure 1 , 6 , 8 and 9 are the first embodiment of the present invention, which provides a safety-improving steam trap. The safety-improving steam trap includes a valve body assembly 100 , a control assembly 200 , an installation assembly 300 and The connection assembly 400, through the arrangement of the connection assembly 400, makes the steam trap more stable during use.

[0033] Specifically, the valve body assembly 100 includes a casing 101 , a fastener 102 disposed on one side of the casing 101 , a water inlet 103 disposed on the top of the casing 101 , and a water outlet 104 disposed at the bottom of the casing 101 . The valve body is provided with a water inlet 103 to improve the efficiency of water and steam inlet, thereby improving the efficiency of the valve in the working process.

[0034]The control assembly 200 is arranged inside the housing 101, and includes a valve seat 201 arranged on the inner bottom wall of the housing 101, a valve flap 202...

Embodiment 2

[0039] refer to Figures 2 to 5 , is the second embodiment of the present invention, which is based on the previous embodiment.

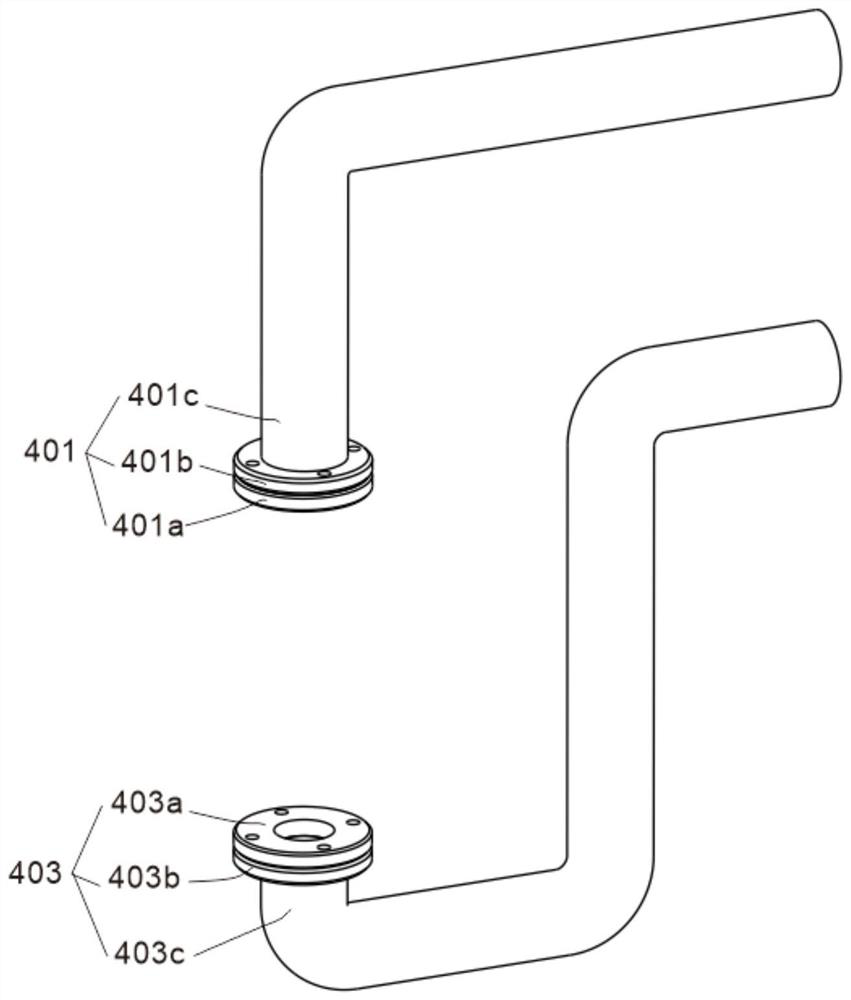

[0040] Specifically, the first connecting member 401 includes a first flange 401a disposed on the top of the water inlet member 103, a second flange 401b disposed on the top of the first flange 401a, and a first flange 401b disposed on the top of the second flange 401b In the pipeline 401c, the first flange 401a and the second flange 401b are screwed together, and the first pipeline 401c is connected with the water inlet pipe in the pipeline through the connection between the first flange 401a and the second flange 401b. The cooperation makes the connection between the first pipe 401c and the water inlet pipe 103b more convenient and stable.

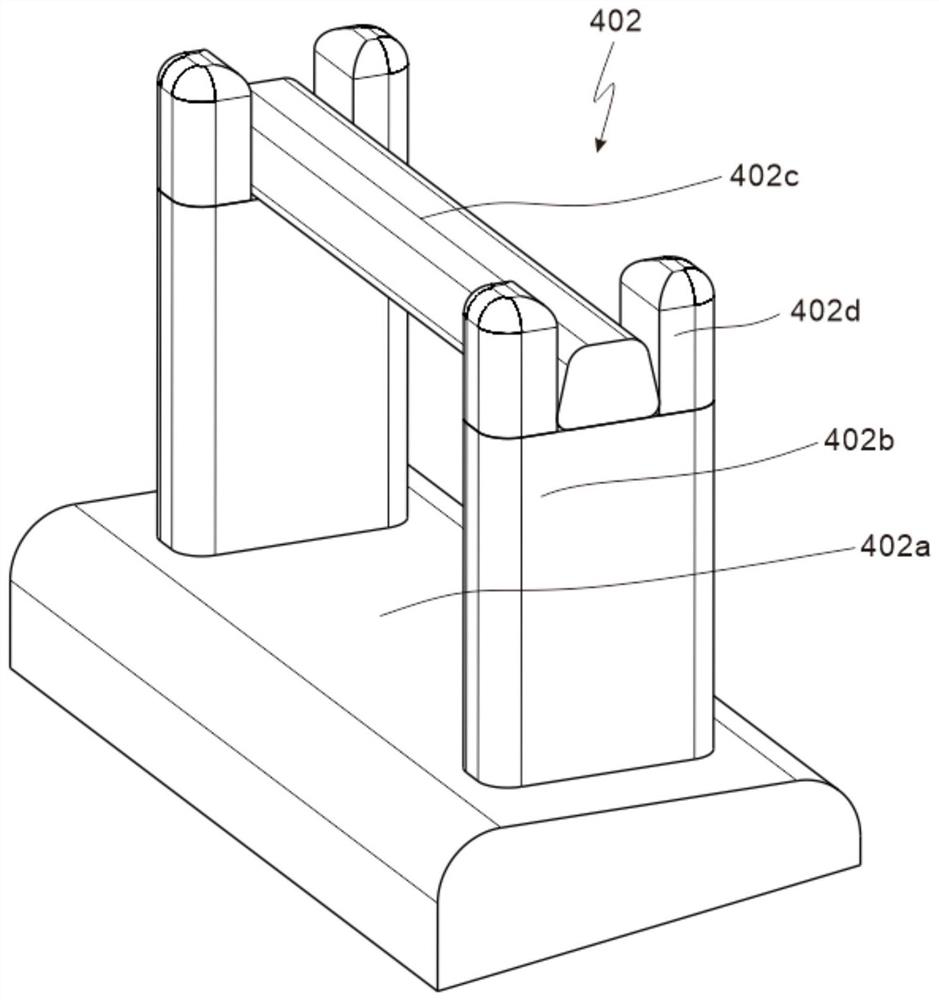

[0041] Preferably, the guard 402 includes a first plate 402a disposed on the top of the housing 101, a fixing block 402b disposed on the top of the first plate 402a, a handle 402c disposed on the top of the f...

Embodiment 3

[0046] refer to Figures 6 to 10 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0047] Specifically, the water inlet 103 includes a first fixing plate 103a arranged on the top of the casing 101, a water inlet pipe 103b arranged in the middle of the first fixing plate 103a, a fixing frame 103c arranged on the inner top wall of the casing 101, The guide plates 103d on both sides of the frame 103c, and the filters 103e arranged on both sides of the fixing frame 103c, the water inlet pipe 103b is arranged above the fixing frame 103c, and the water outlet 104 includes a second fixing plate 104a arranged at the bottom of the casing 101 , a water outlet pipe 104b arranged in the middle of the second fixed plate 104a, and a first emptying groove 104c arranged inside the second fixed plate 104a and communicated with the water outlet pipe 104b, when the condensed water enters the inside of the valve through the water inlet pipe 103b A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com