Time-pressure method accurate filling system applied to blowing, filling and sealing all-in-one machine

A time pressure, filling system technology, applied in the direction of liquid bottling, packaging, bottling machines, etc., can solve the problems of inaccurate control and low precision of the filling system, and achieve short stabilization time, compact installation space and easy disassembly Easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

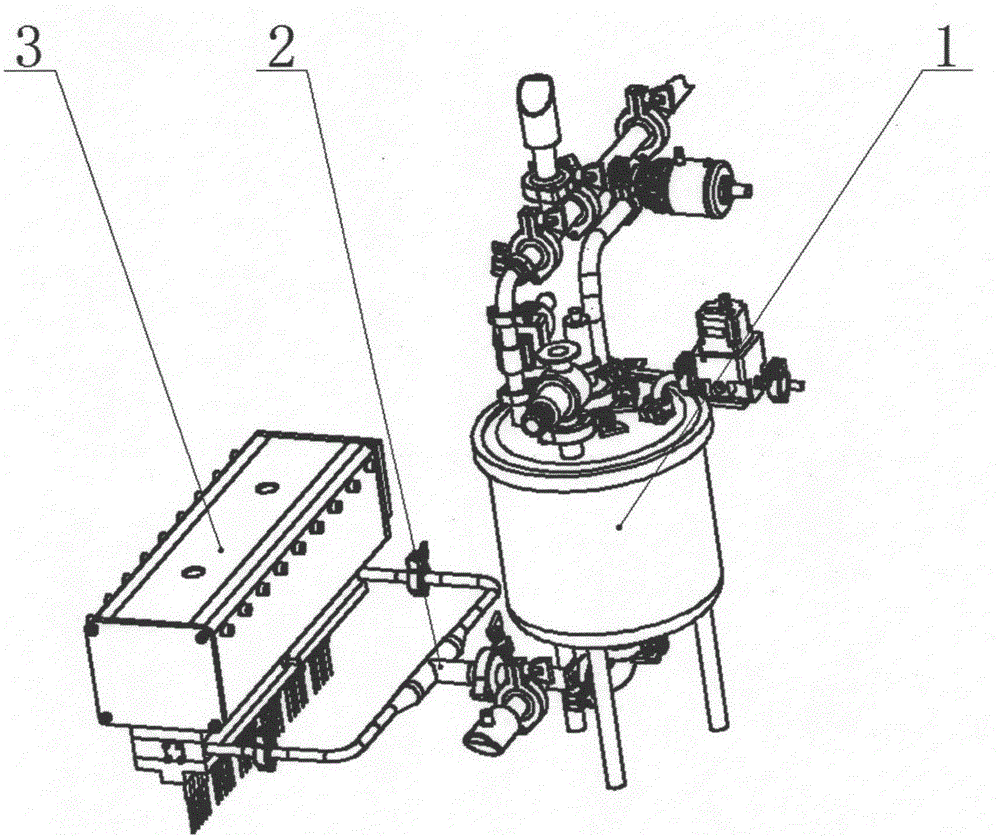

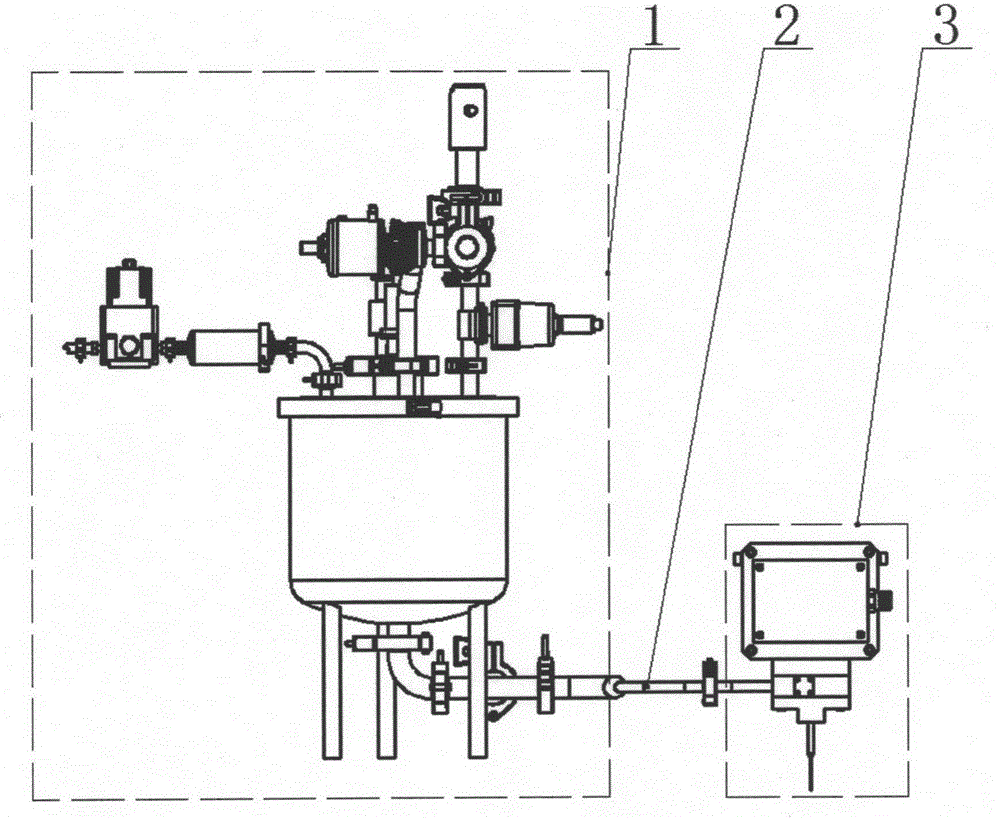

[0031] Such as Figure 1-2 As shown, a time-pressure method accurate filling system provided by the present invention includes a constant pressure system 1 and a filling head 3 connected through a distribution pipe 2 . The constant pressure system 1 is connected with the distribution pipe 2 through sanitary clamp joints, seals and clamps. The dispensing pipe 2 is connected with the filling head 3 through a sanitary clamp joint, a seal and a clamp. In the time pressure method filling system, the filling valve 3-6 in the filling head 3 can be controlled for filling after the constant pressure system 1 reaches pressure balance.

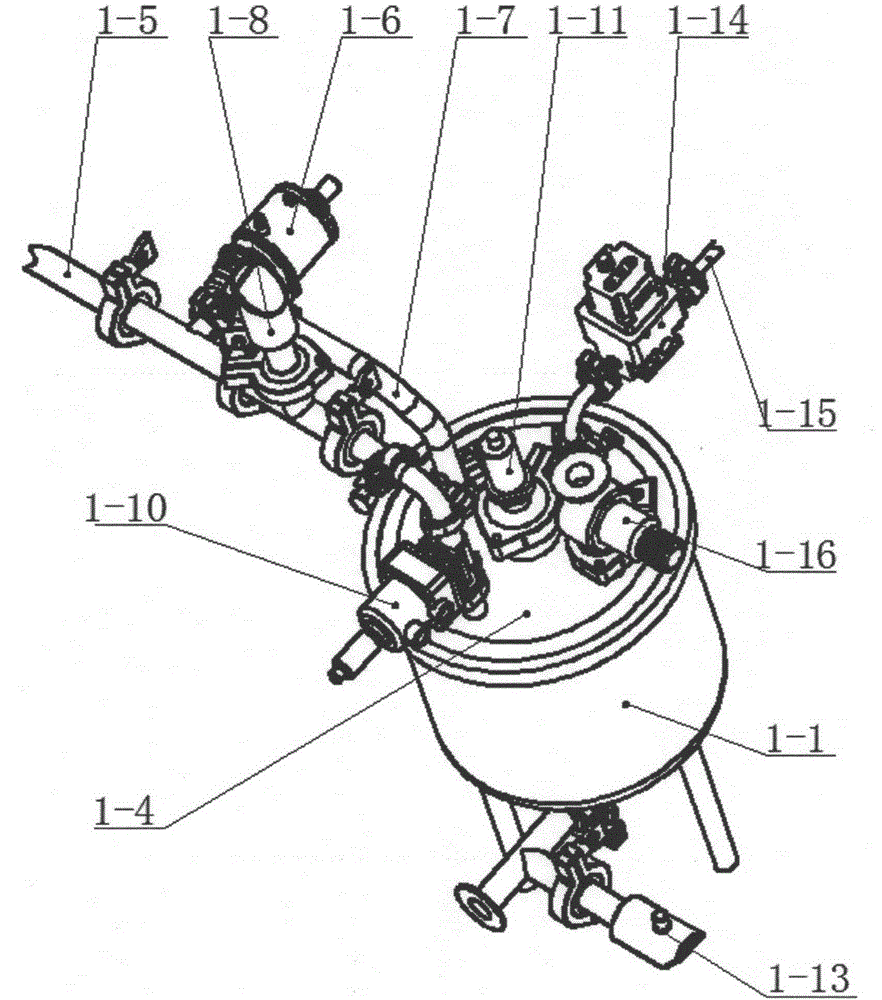

[0032] Such as Figure 2-4 As shown, the constant pressure system 1 includes a tank body 1-1 with a tank cover 1-4, a clamp seal 1-2 is provided between the tank body 1-1 and the filling cover 1-4 and passes through the clamp 1-3 Connect to form a buffer tank. The main components of the precise liquid replenishment control system in the constant pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com