Electric connector tinning device

A technology for electrical connectors and guide posts, which is applied in the field of tinning devices for electrical connectors, to achieve the effects of ensuring welding quality, simple operation, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

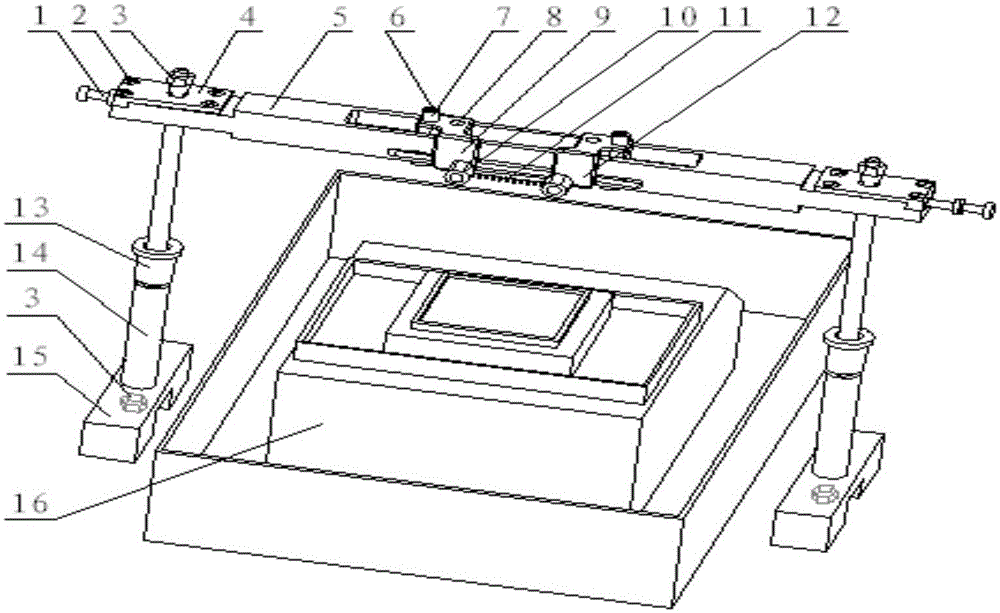

[0036] The embodiment of the present invention provides an electrical connector tinning device, such as Figure 1-7 As shown, it is used for tinning the solder pins of the electrical connector 11. The electrical connector 11 can be a rectangular electrical connector or a circular electrical connector. The tinning device for the electrical connector includes:

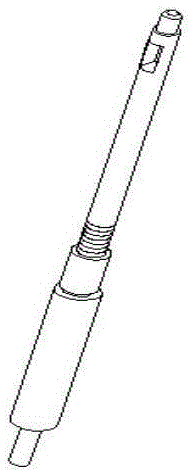

[0037] Guide post 14, two guide posts 14 are arranged on the base 15 in left and right distribution, and are fixed by nut 3;

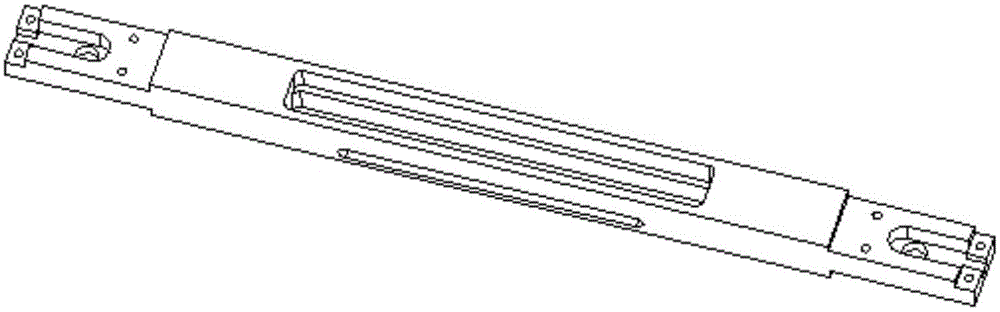

[0038] The positioning plate 5, the two ends of the positioning plate 5 are respectively sleeved on the guide post 14, and can move up and down along the guide post 14;

[0039] The handle 1 is arranged at both ends of the positioning plate 5, and is used to limit the position of the positioning plate 5 after it is lifted;

[0040] The left positioning block 9 and the right positioning block 12 are arranged on the positioning plate 5 for fixing the electrical connector 11;

[0041] The limit sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com