Strength testing system of speed changer shifting fork

A technology of shifting fork and strength testing, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of lack of quantifiable test methods for the deformation of transmission shifting fork, and achieves reduction of errors, high test accuracy, and practicality. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

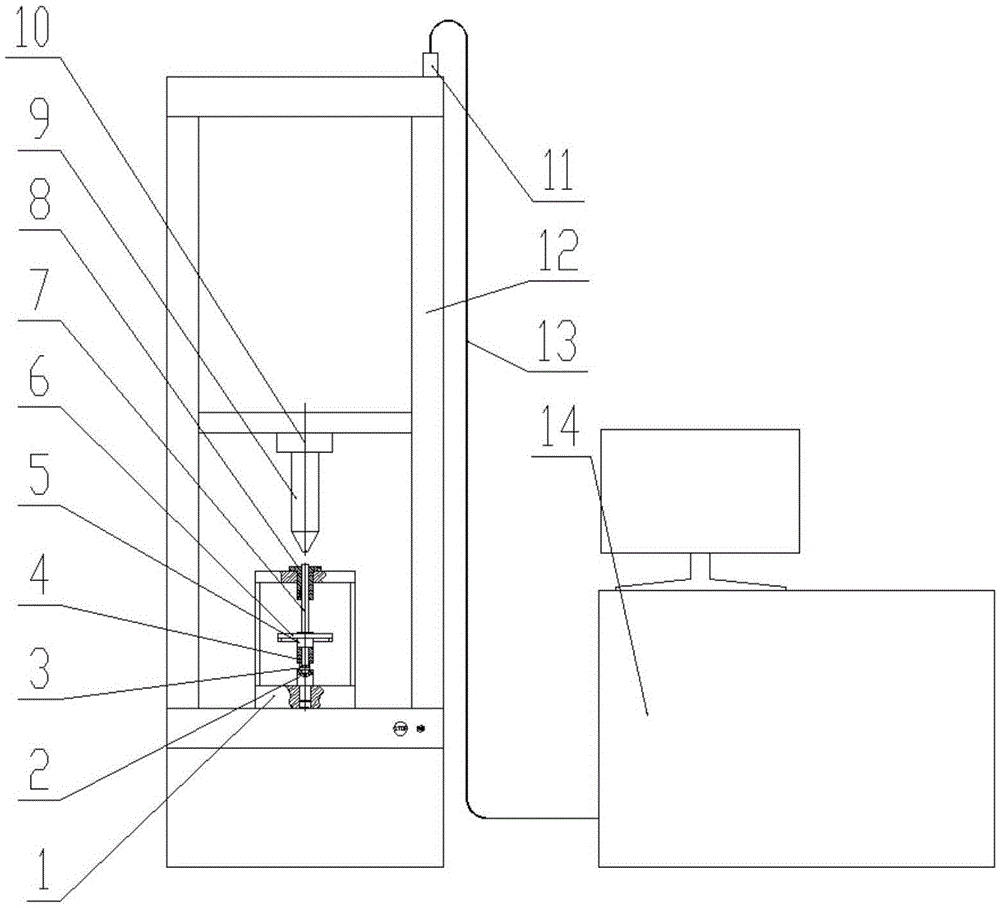

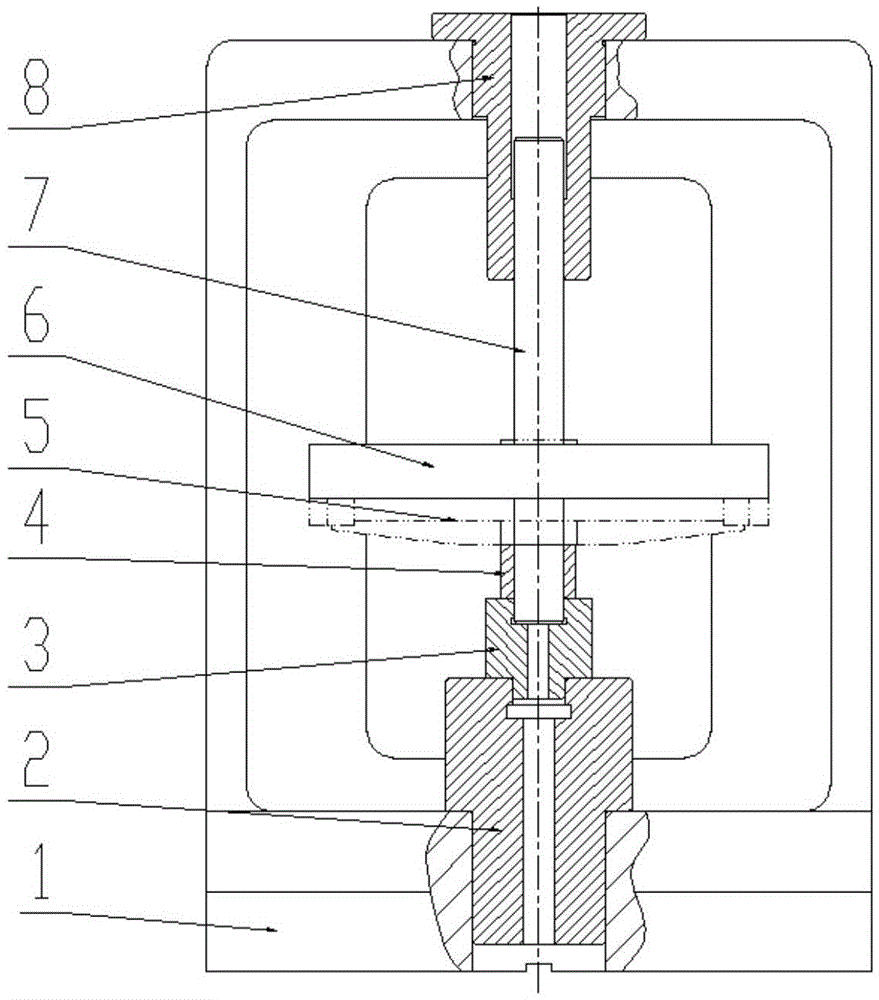

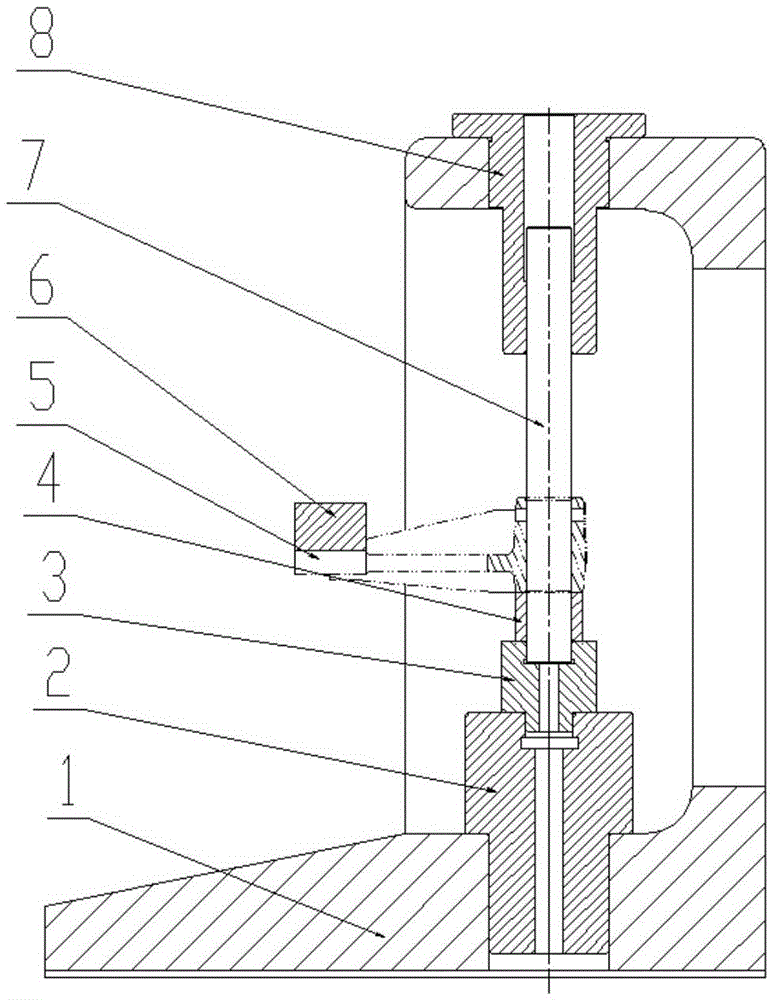

[0020] Such as Figure 1-3 As shown, a transmission shift fork strength test system includes an execution unit, a data acquisition unit, a working state simulation unit and a data processing unit, wherein the execution unit is a screw press 12, and the data acquisition unit is a Angular displacement sensor 11 and a pressure sensor 10, the working state simulation unit is composed of base 1, fixed guide rod 2, quick change pressure head 3, adjustment sleeve 4, pressure plate 6, shift fork shaft guide sleeve 8, pressure sensor 10, displacement The sensor 11 is installed on the screw screw press 12 , and the pressure head 9 is installed on the pressure sensor 10 . During the test, the tested shift fork 5 is installed in the working state simulation unit, the fixed guide rod 2 is fixed on the base 1, and the appropriate quick-change indenter 3, adjustment sleeve 4, and pressure plate 6 are selected according to the specification and model of the shift fork 5 , shift fork shaft 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com