Data processing method and apparatus and terminal

A data processing and data technology, applied in the field of data processing, can solve problems such as inconvenient verification of process card data, save manpower and time, and improve verification efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

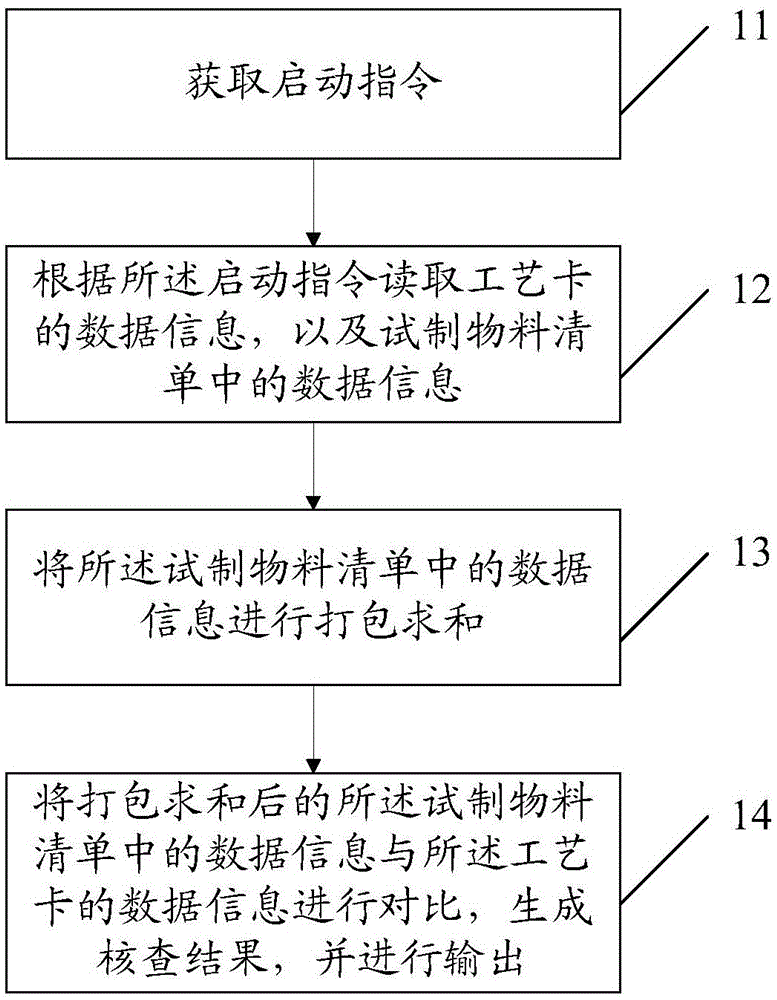

[0072] Such as figure 1 As shown, the data processing method in Embodiment 1 of the present invention is applied to the data verification of the process card, and the data processing method includes:

[0073] Step 11: Get the startup command;

[0074] Step 12: Read the data information of the process card and the data information in the trial-manufacturing bill of materials according to the start-up instruction;

[0075] Step 13: Pack and sum the data information in the trial-manufacturing bill of materials;

[0076] Step 14: Compare the data information in the trial-manufacturing bill of materials after packaging and summing with the data information in the process card, generate a verification result, and output it.

[0077] The data processing method provided by Embodiment 1 of the present invention directly reads the data information of the process card and the data information in the trial-manufacturing bill of materials after obtaining the start-up command, and process...

Embodiment 2

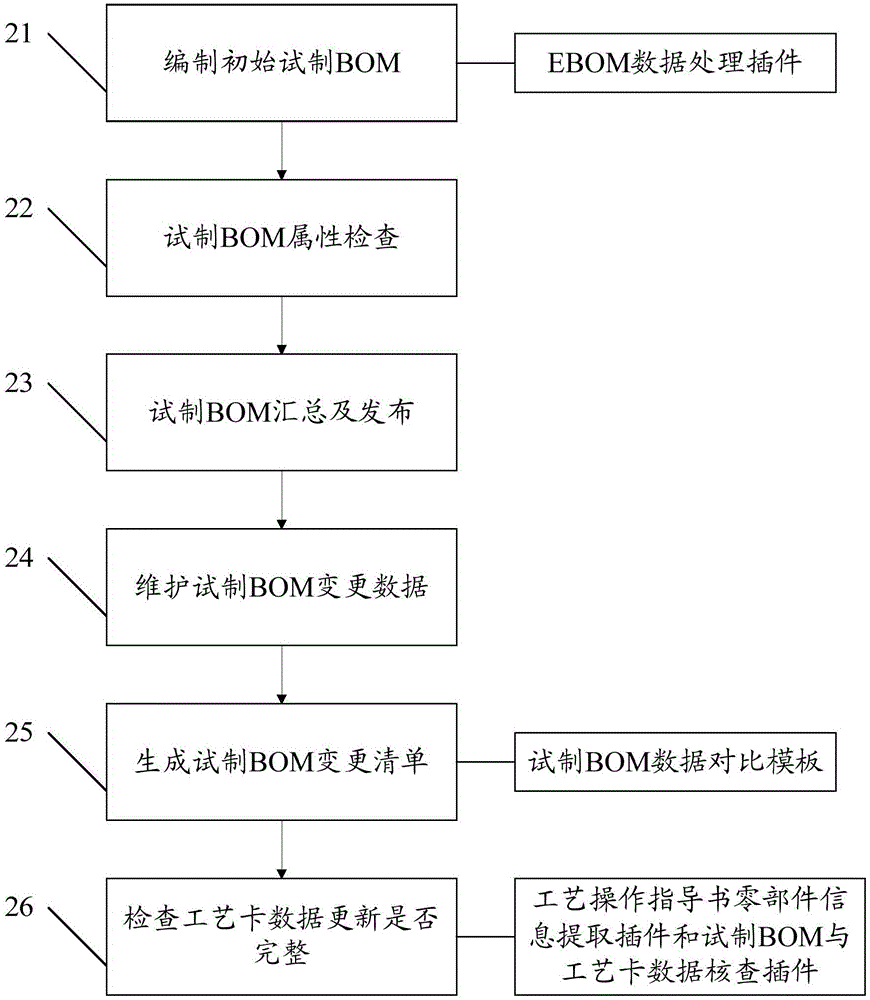

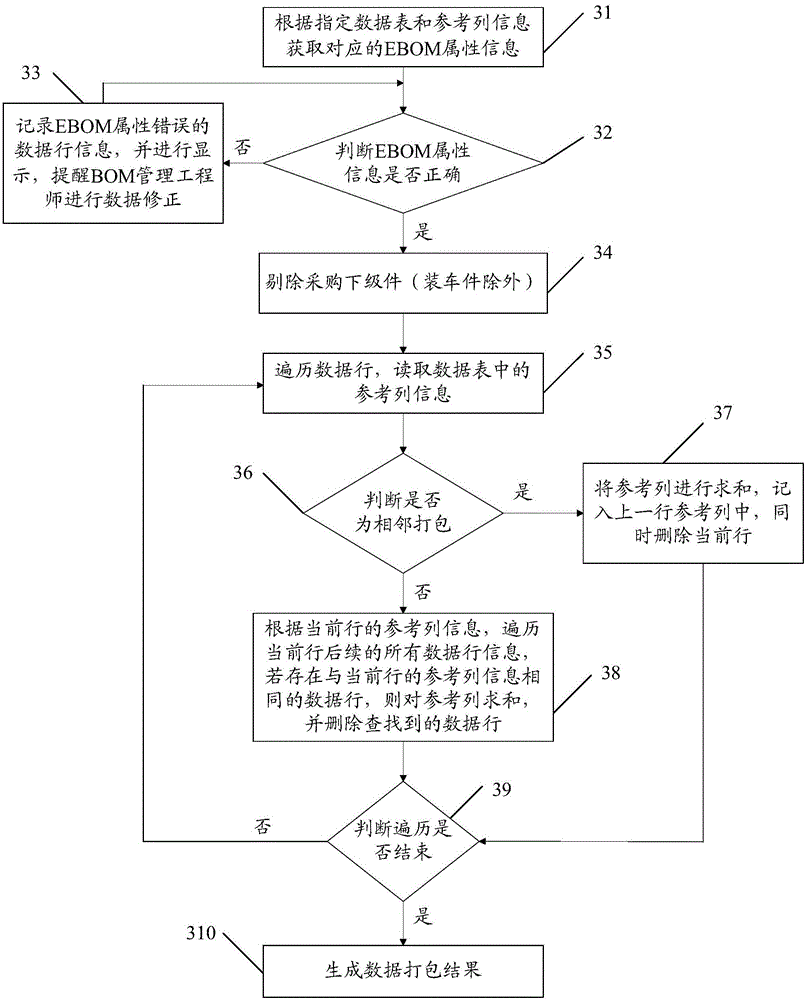

[0091] Embodiment 2 of the present invention develops the EBOM data processing plug-in (comprising the function of extracting the trial-manufactured BOM parts list and the function of parts packaging processing), in order to effectively remove the purchased lower-level parts, and can merge the EBOM data; the data based on the EXCEL macro The comparison plug-in template is applied to the comparison between the trial-production BOM versions: put the two different versions of the trial-production BOM data into the data comparison plug-in template to generate the data change information of the two versions before and after. The change information is based on the change content, according to different The color is displayed, which vividly shows the data changes in a certain period of time; the plug-in for extracting parts information from the process operation instruction is developed to extract the required data according to the requirements of the process operation instruction temp...

Embodiment 3

[0152] Such as Figure 8 As shown, the data processing device in the third embodiment of the present invention is applied to the data verification of the process card, and the data processing device includes:

[0153] An acquisition module 81, configured to acquire a startup instruction;

[0154] The reading module 82 is used to read the data information of the process card and the data information in the bill of materials for trial production according to the start instruction;

[0155] A summing module 83, configured to package and sum the data information in the trial-manufacturing bill of materials;

[0156] The first processing module 84 is configured to compare the data information in the trial-manufacturing bill of materials after packaging and summation with the data information in the process card, generate a verification result, and output it.

[0157] The data processing device provided in Embodiment 3 of the present invention directly reads the data information o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com