Novel AC contactor

An AC contactor, a new type of technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of affecting the mechanical life of the product, extending the moving distance, reducing the arc blowing magnetic field in the arc starting space, etc., and achieving a stable fastening effect Reliable, prevent phase-to-phase breakdown, and improve the effect of creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

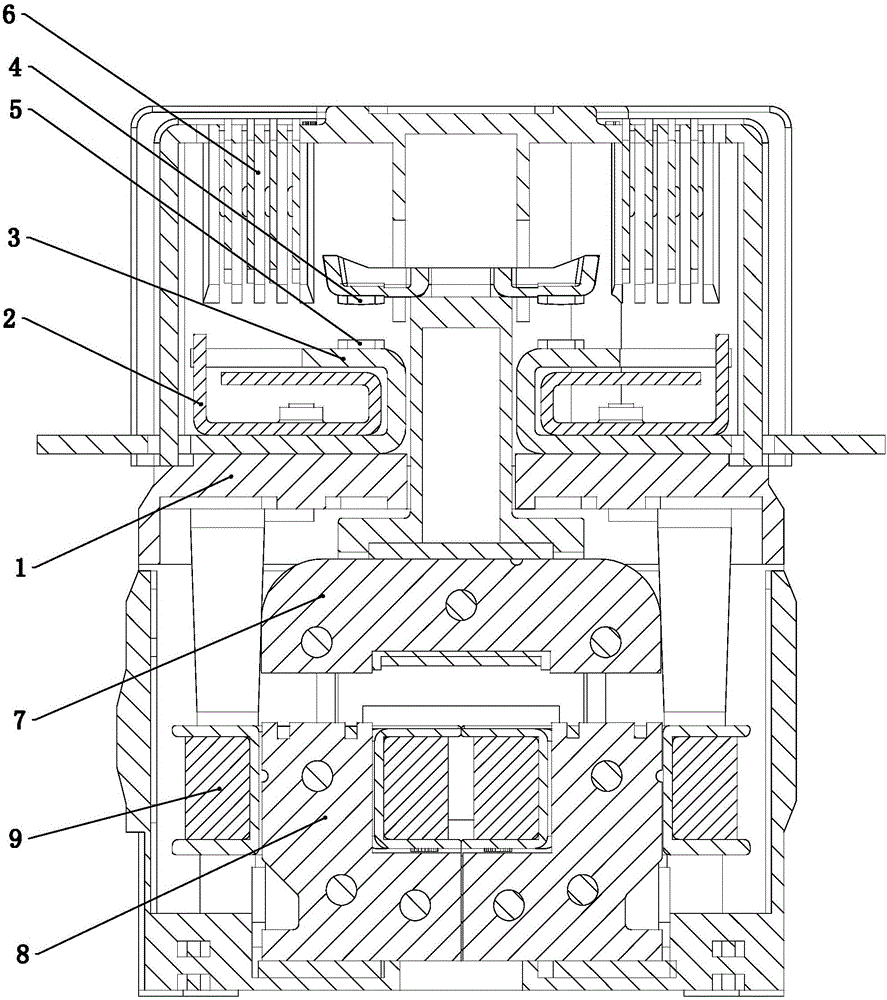

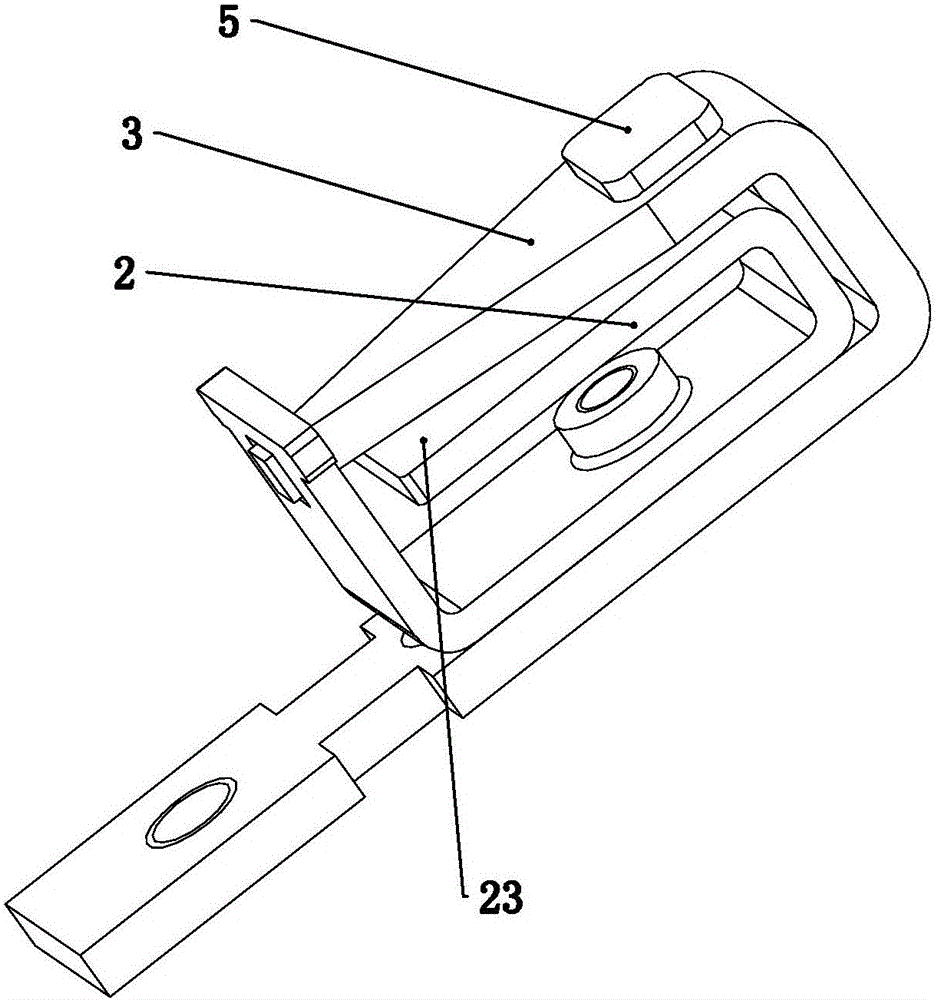

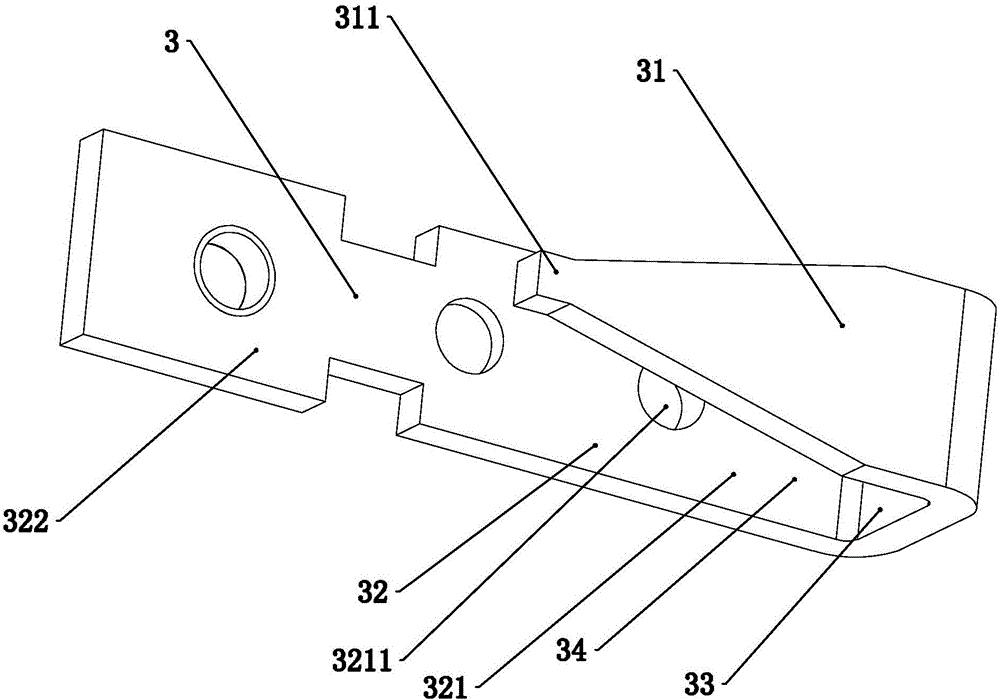

[0014] Such as figure 1 — Figure 5 As shown, a new type of AC contactor includes a bottom plate 1, a magnetic plate 2, a contact plate 3, a moving contact 4, a static contact 5, an arc extinguishing chamber 6, an armature 7, an iron core 8 and a coil 9. The moving contact 4 is set in linkage with the armature 7, the static contact 5 is set on the contact plate 3, and the armature 7 can drive the moving contact 4 to move to realize the conduction and disconnection with the static contact 5. The above technology is now It also exists in the existing technology, so it will not be described in detail in this embodiment. In this embodiment, the magnetic conductive plate 2 is formed by bending a metal plate, and the magnetic conductive plate 2 is generally frame-shaped. 2 includes two horizontal sides 211, 212 and two vertical sides 221, 222, the two horizontal sides are respectively the lower horizontal side 211 and the upper horizontal side 212, and the two vertical sides are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com